Sb2Se3 film and preparation method and application thereof

A sb2se3, thin film technology, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency of solar cells, and achieve the effect of reducing defect types and defect concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

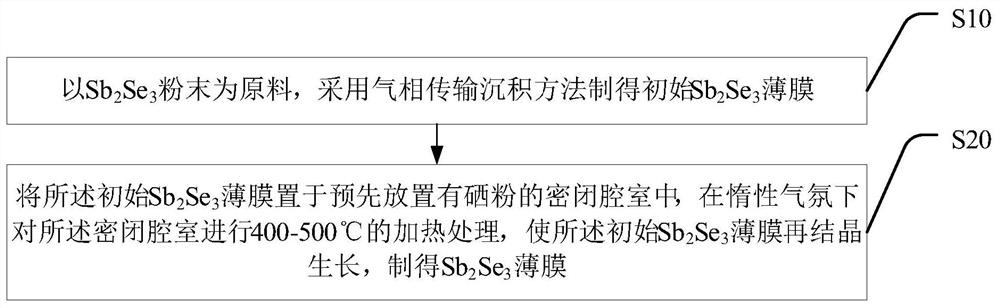

[0046] a Sb 2 Se 3 The preparation method of thin film, comprises the following steps:

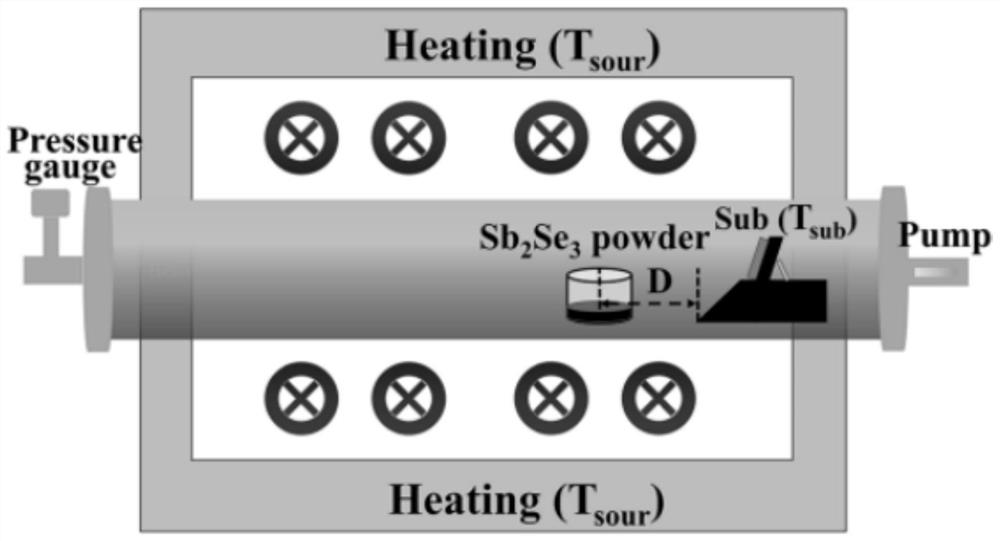

[0047] 1. Add Sb 2 Se 3 The powder was placed in a tube furnace with two temperature zones, and the initial Sb was prepared on the substrate by the vapor transport deposition method. 2 Se 3 film;

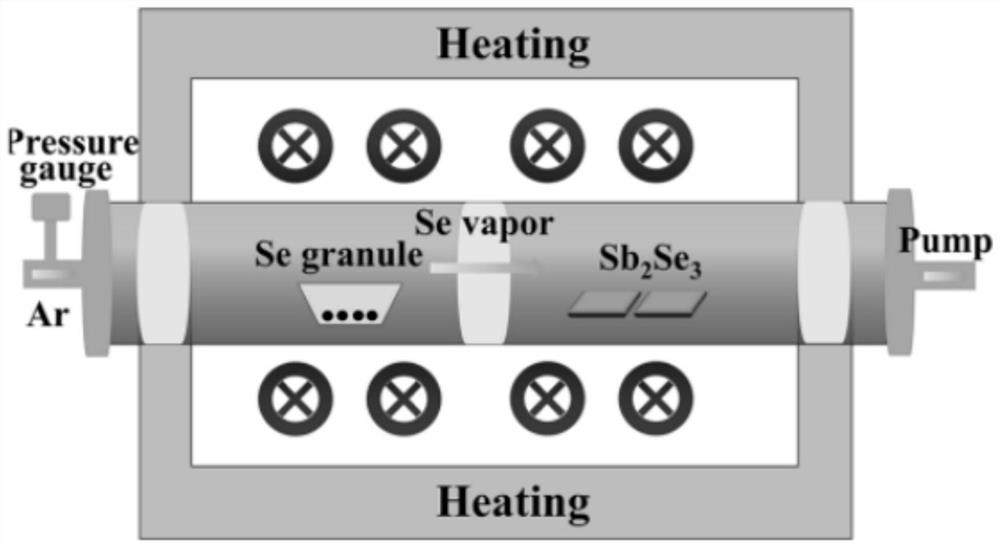

[0048] 2. Then the initial Sb 2 Se 3 The film was placed in a dual-temperature zone tube furnace with selenium powder placed in advance, and high-purity Ar gas was introduced into the dual-temperature zone tube furnace to stabilize the pressure in the furnace to 5×10 4 Pa, heat treatment at 420°C for 20 minutes in the dual temperature zone tube furnace to promote the initial Sb 2 Se 3 Film recrystallization and re-growth to produce high-quality Sb with closely packed micron-sized grains, benign grain boundaries, and high carrier mobility direction-preferential orientation growth 2 Se 3 film.

[0049] The Sb that comparative example 1 and embodiment 1 make respectively 2 Se 3 Film p...

Embodiment 2

[0051] a Sb 2 Se 3 The preparation method of thin film, comprises the following steps:

[0052] 1. Add Sb 2 Se 3 The powder was placed in a tube furnace with two temperature zones, and the initial Sb was prepared on the substrate by the vapor transport deposition method. 2 Se 3 film;

[0053] 2. Then the initial Sb 2 Se 3 The film is placed in a dual-temperature zone tube furnace with selenium powder placed in advance, and high-purity helium is introduced into the dual-temperature zone tube furnace to stabilize the pressure in the furnace to 6×10 4 Pa, heat treatment at 480°C for 25 minutes in the dual temperature zone tube furnace to promote the initial Sb 2 Se 3 Film recrystallization and re-growth to produce high-quality Sb with closely packed micron-sized grains, benign grain boundaries, and high carrier mobility direction-preferential orientation growth 2 Se 3 film.

Embodiment 3

[0055] a Sb 2 Se 3 The preparation method of thin film, comprises the following steps:

[0056] 1. Add Sb 2 Se 3 The powder was placed in a tube furnace with two temperature zones, and the initial Sb was prepared on the substrate by the vapor transport deposition method. 2 Se 3 film;

[0057] 2. Then the initial Sb 2 Se 3 The film is placed in a dual-temperature zone tube furnace with selenium powder placed in advance, and high-purity helium is introduced into the dual-temperature zone tube furnace to stabilize the pressure in the furnace to 4×10 4 Pa, heat treatment at 400°C for 15 minutes in the dual temperature zone tube furnace to promote the initial Sb 2 Se 3 Film recrystallization and re-growth to produce high-quality Sb with closely packed micron-sized grains, benign grain boundaries, and high carrier mobility direction-preferential orientation 2 Se 3 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com