Aqueous zinc metal battery MXene-based diaphragm as well as preparation method and application thereof

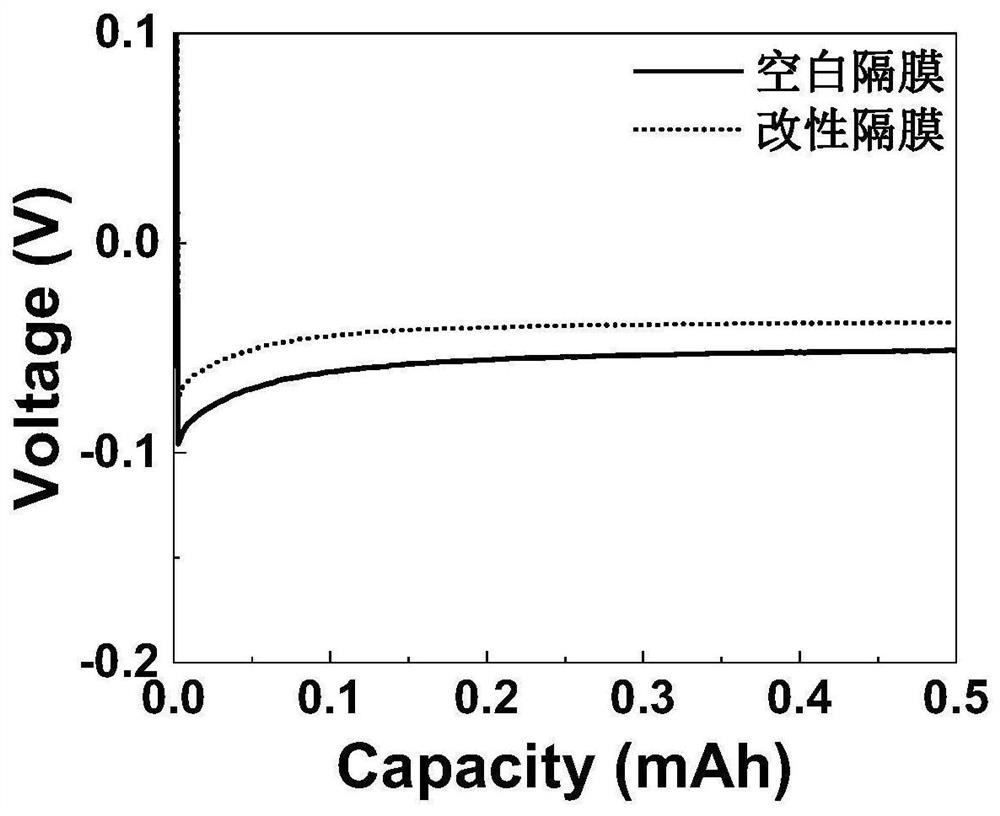

A zinc metal and zinc battery technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as poor cycle stability and dendrite growth, achieve dendrite growth inhibition, easy operation, and accelerated migration and transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the present invention provides a method for preparing an MXene-based diaphragm for a water-based zinc metal battery, comprising: soaking the diaphragm into a concentrated solution of an MXene colloidal solution.

[0037] In one or more embodiments of the present invention, the preparation step of the MXene colloidal solution includes: dissolving the powder of the MAX phase in a mixed solution of hydrochloric acid and fluoride, peeling off the MXene, and separating the obtained few-layer or multi-layer MXene Colloidal solution;

[0038]More specifically, the preparation step of the MXene colloidal solution is usually to stir the powder of the MAX phase in a mixed solution of hydrochloric acid and fluoride, then add water and centrifugally wash to remove excess acid and fluoride, and then peel off the multilayer MXene by Ultrasonic stripping or adding a layering reagent and centrifuging to separate the obtained few-layer or multi-layer MXene colloidal...

Embodiment 1

[0051] A highly stable MXene-based diaphragm, the preparation process includes the following steps:

[0052] (1) Preparation of MXene colloidal solution: Ti 3 AlC 2 The MAX phase was etched with hydrochloric acid and lithium fluoride to remove aluminum, washed to remove acid and other impurities, then added deionized water to disperse, shaken by hand, and centrifuged to obtain Ti 3 C 2 T x MXene colloidal solution;

[0053] (2) Preparation of MXene colloidal solution concentrate: the above-mentioned Ti 3 C 2 T x The MXene colloidal solution was centrifuged in a high-speed centrifuge at a speed of 9000r / min for 5 minutes, half of the clearer liquid in the upper part was removed, and the remaining liquid and the bottom sediment were shaken evenly to obtain a concentrated MXene colloidal solution.

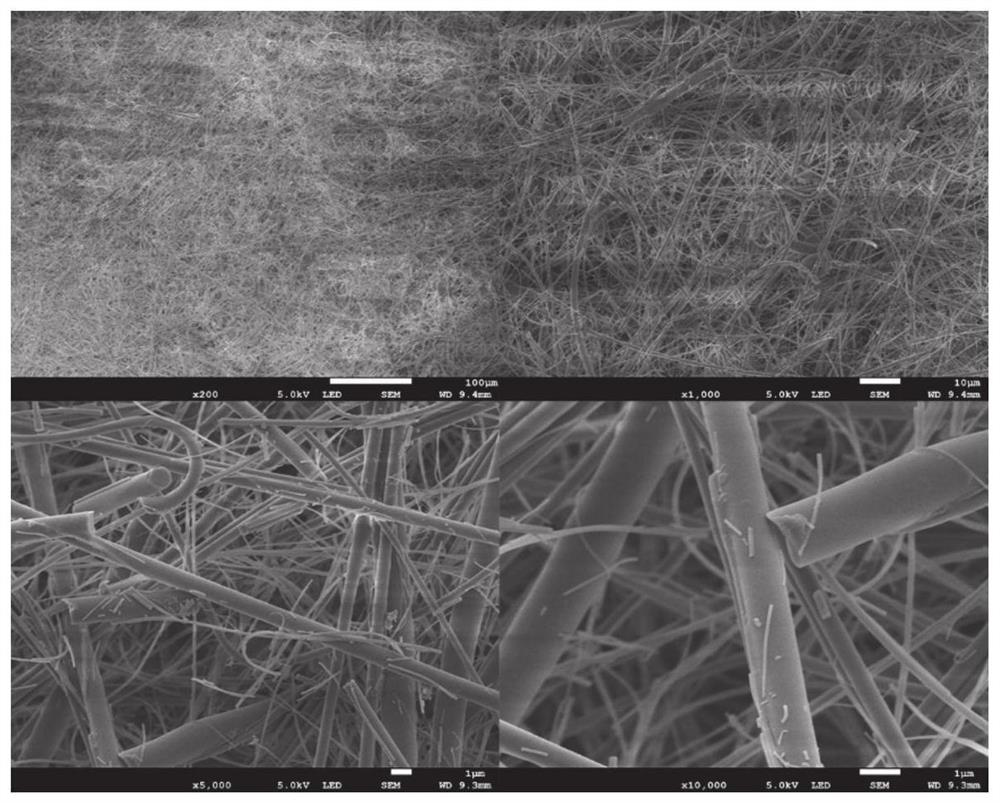

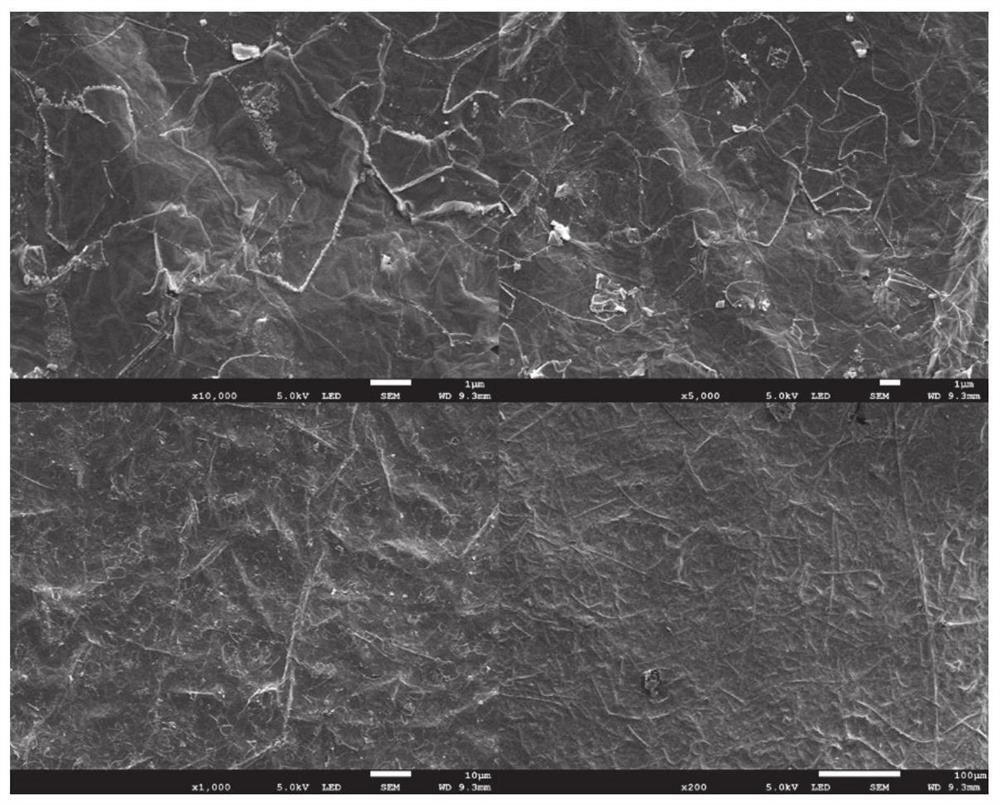

[0054] (3) Soak the Whatman glass fiber diaphragm in the above-mentioned concentrated MXene colloidal solution for 1 min, take out the sample, and dry it in a vacuum oven to o...

Embodiment 2

[0057] A highly stable MXene-based diaphragm, the preparation process includes the following steps:

[0058] (1) Preparation of MXene colloidal solution: Ti 3 AlC 2 The MAX phase was etched with hydrochloric acid and lithium fluoride to remove aluminum, washed to remove acid and other impurities, then added deionized water to disperse, shaken by hand, and centrifuged to obtain Ti 3 C 2 T x MXene colloidal solution;

[0059] (2) Preparation of MXene colloidal solution concentrate: the above-mentioned Ti 3 C 2 T x The MXene colloidal solution was centrifuged in a high-speed centrifuge at a speed of 9000r / min for 5 minutes, half of the clearer liquid in the upper part was removed, and the remaining liquid and the bottom sediment were shaken evenly to obtain a concentrated MXene colloidal solution.

[0060] (3) Put the concentrated MXene colloid solution in the spray gun, spray it on the surface of the Whatman glass fiber diaphragm, and then dry the sample in a vacuum ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com