Preparation method of modified carbon fiber/SiO2 aerogel composite material

A composite material and modified carbon technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of general mechanical properties of composite materials, weak bonding ability between fibers and matrix, etc. The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of airgel composite material is carried out according to the following steps:

[0059] Step 1: Carbon Fiber Modification:

[0060] (1) Desizing:

[0061] A carbon fiber (Toray T700 CF) fiber segment with a length of 2 m was selected, and the carbon fiber was dried in a vacuum oven to obtain a dry carbon fiber precursor. Then carry out desizing treatment to carbon fiber, put carbon fiber into the mixed solution of acetone and ethanol (volume ratio is 1:1), and carry out ultrasonic treatment desizing 6h, should pay attention to keep solution temperature below 56 ℃ in this process (acetone The boiling point is 56.53°C). After the desizing is completed, the acetone solution on the surface of the carbon fiber is rinsed with ethanol, and then the carbon fiber is put into a vacuum drying oven for drying treatment. The oven temperature is 80°C, and the drying time is 6 hours.

[0062] (2) surface oxidation:

[0063] After desizing the carbon fiber sur...

Embodiment 2

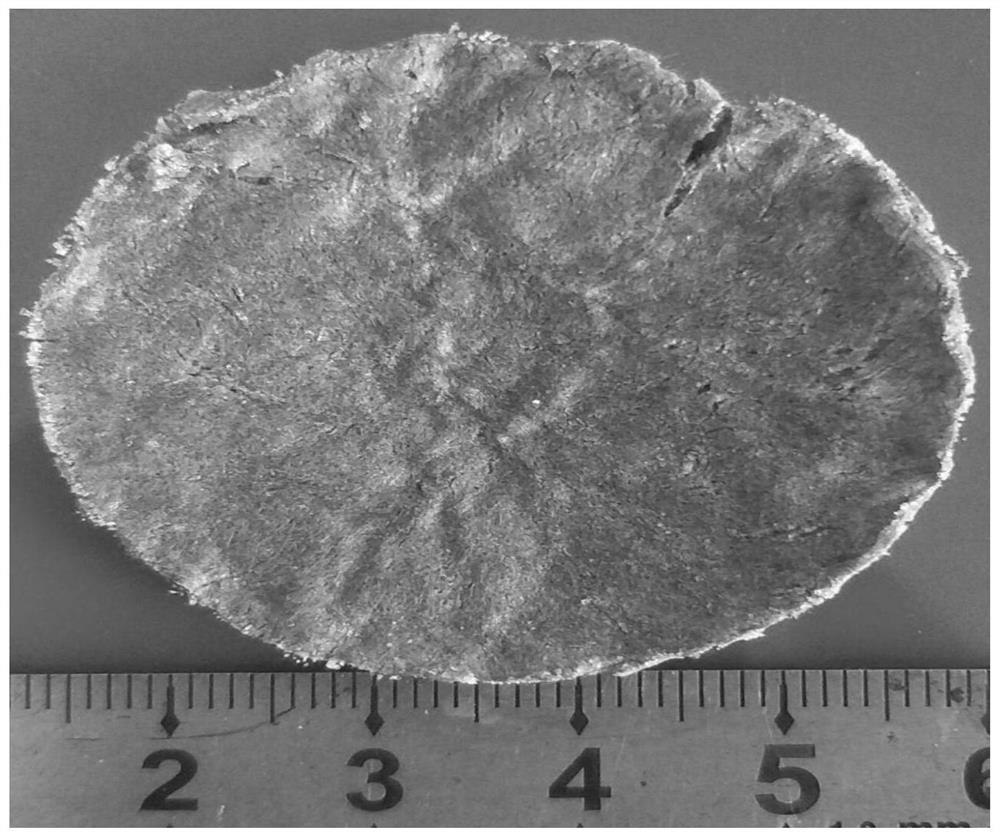

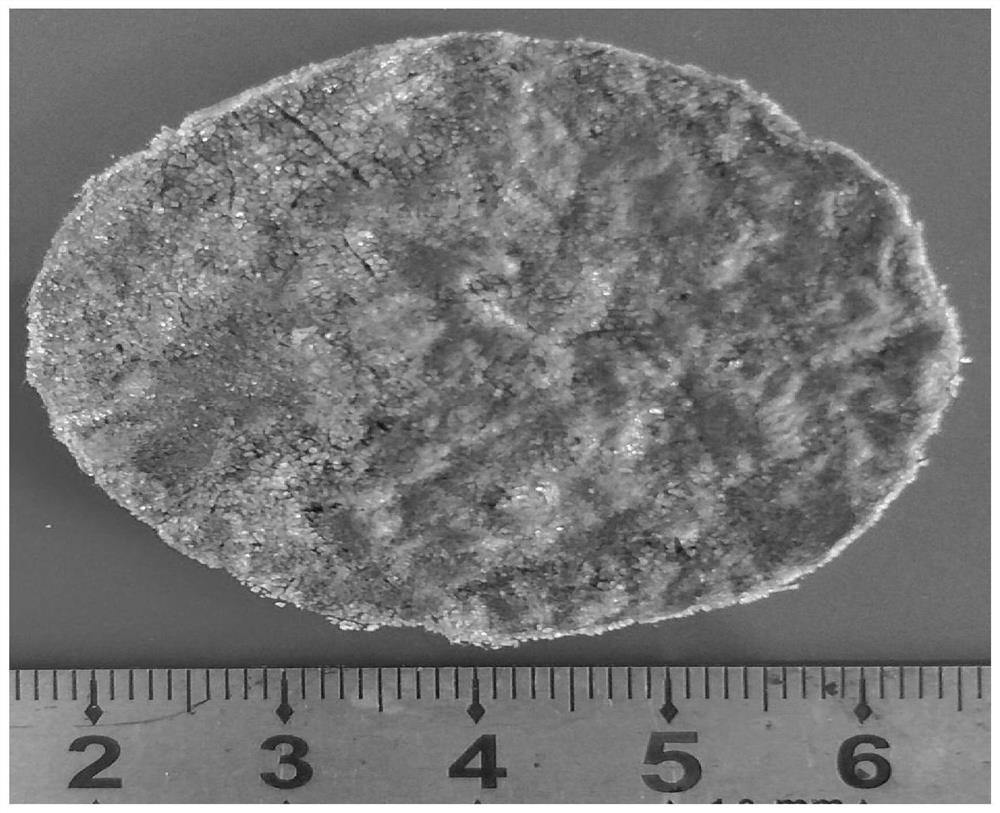

[0076] Other operating steps are the same as in Example 1, the difference is that the mass fraction of carbon fiber accounts for 2wt% of the total mass of carbon fiber and silica gel. For specific sample diagrams, see figure 2 shown.

Embodiment 3

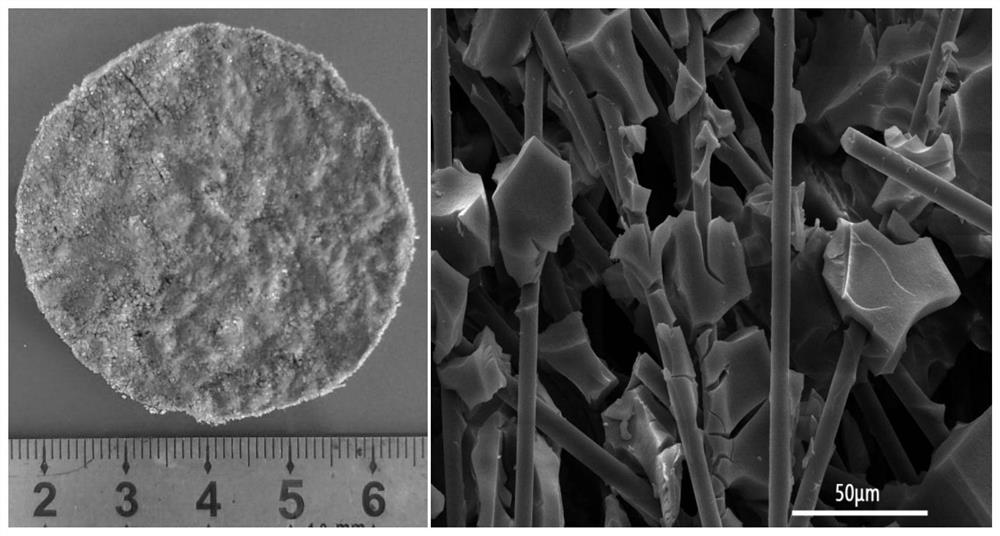

[0078] Other operating steps are consistent with Example 1, the difference is that the mass fraction of carbon fiber accounts for 1wt% of the total mass of carbon fiber and silica gel. For specific sample pictures and SEM pictures, see image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com