Alkali-resistant coating slurry, crucible with alkali-resistant coating and preparation method

A technology of alkali resistance and coating slurry, which is applied in crucible furnace, lighting and heating equipment, electrode manufacturing, etc. It can solve the problems that the material is easy to react with the crucible, the positive electrode material is easy to stick to the wall, and the service life is short, so as to achieve improvement Wall sticking phenomenon, performance without side effects, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

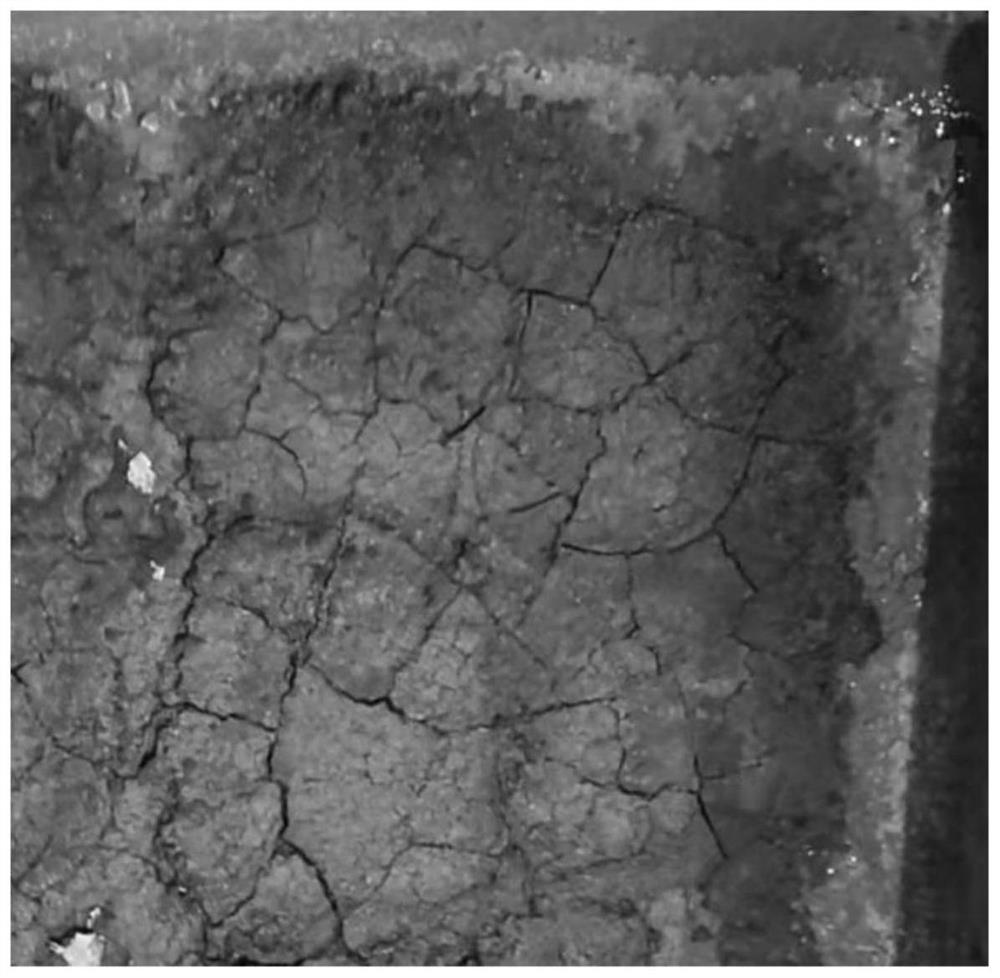

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a crucible with an alkali-resistant coating, comprising the following steps:

[0037] filling the crucible base with the slurry, standing for 1-2 minutes, pouring out the slurry in the crucible base, standing for 12-48 hours, drying and sintering to obtain a crucible with an alkali-resistant coating.

[0038] In the present invention, the slurry is the above-mentioned alkali-resistant coating slurry.

[0039] In the present invention, the crucible base is preferably a mullite crucible, a corundum mullite crucible or a cordierite mullite crucible, more preferably a mullite crucible.

[0040] In the present invention, the standing time after pouring out the slurry in the crucible base is preferably 12-48 hours, more preferably 26-42 hours, and more preferably 36 hours.

[0041] In the present invention, the drying temperature is preferably 25-80°C, more preferably 28-60°C, more preferably 35°C; the drying time is...

Embodiment 1

[0047] This embodiment provides a crucible with an alkali-resistant coating, and the preparation method comprises the following steps:

[0048] (1) Add 21g aluminum phosphate (particle size is 8 μm), 0.2g sodium polyacrylate, 0.24g sodium carboxymethyl cellulose to 200g deionized water, after fully stirring and mixing, a slurry with good fluidity is obtained;

[0049](2) Clean up the mullite crucible matrix with a hairbrush, then fill the mullite crucible matrix with the slurry in step (1), let it stand for 1min, pour out the slurry in the mullite crucible matrix, and let it stand Set aside for 28 hours, dry at 32°C for 36 hours, and then sinter at 1080°C for 36 hours to obtain a crucible with an alkali-resistant coating with a thickness of 0.2 mm.

Embodiment 2

[0051] This embodiment provides a crucible with an alkali-resistant coating, and the preparation method comprises the following steps:

[0052] (1) Add 150g of calcium phosphate (particle size is 15 μm), 1.6g of ammonium polyacrylate, and 2g of carboxymethyl cellulose into 2000g of deionized water, and after fully stirring and mixing, a slurry with good fluidity is obtained;

[0053] (2) Clean the corundum mullite crucible matrix with a brush, then fill the corundum mullite crucible matrix with the slurry in step (1), let it stand for 1min, and pour out the slurry in the corundum mullite crucible matrix The material was left to stand for 30 hours, dried at 35°C for 24 hours, and then sintered at 1300°C for 20 hours to obtain a crucible with an alkali-resistant coating with a thickness of 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com