Non-yellowing polyurethane character filling material for rubber coating layer of fitness equipment and preparation method of non-yellowing polyurethane character filling material

A technology of fitness equipment and polyurethane, which is applied in the field of non-yellowing polyurethane filler material for the rubber layer of fitness equipment and its preparation, can solve the problems that the filler material is easy to break, fall off, and affect the display of the filler, so as to improve the strength, toughness, Improve the effect of waterproof and avoid breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

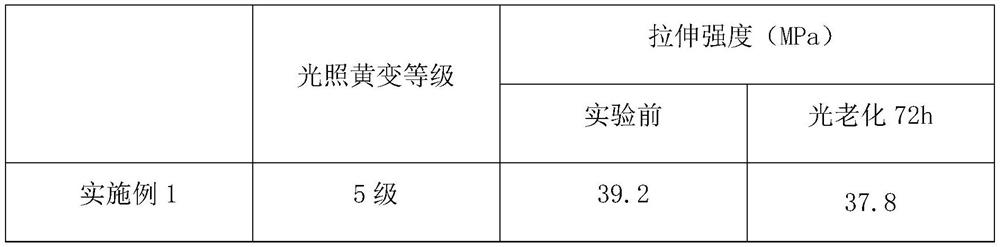

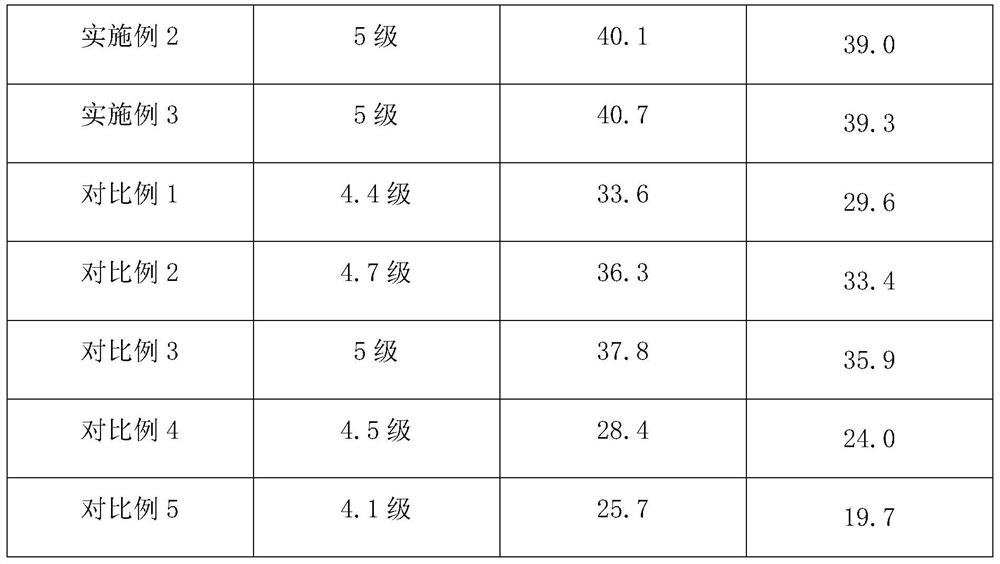

Examples

Embodiment 1

[0038] (1) Preparation of chain extender:

[0039] Take N,N-dimethylacetamide, in a nitrogen atmosphere, add 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane, 1,3-diaminopropyltetramethyldi Siloxane, stir for 10min, add 3,3',4,4'-hexafluoroisopropyl bis(phthalic anhydride), stir, react for 24h, heat up to 160°C, add xylene, react for 6h, wash , dried to obtain a chain extender; 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane, 3,3',4,4'-hexafluoroisopropylbis(phthal Anhydride), the mass ratio of 1,3-diaminopropyltetramethyldisiloxane is 50:44:25;

[0040] (2) Preparation of modified polymer:

[0041] a. Preparation of Product A:

[0042] Take borax, mix it with deionized water, add dopamine hydrochloride in a nitrogen atmosphere, stir for 10 minutes, add sodium carbonate, adjust the system temperature to 7°C, add methacryloyl chloride, keep the temperature, stir for 10 minutes, return to room temperature, and react 12h, extraction and drying to obtain product A; the molar ...

Embodiment 2

[0052] (1) Preparation of chain extender:

[0053] Take N,N-dimethylacetamide, in a nitrogen atmosphere, add 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane, 1,3-diaminopropyltetramethyldi Siloxane, stir for 12min, add 3,3',4,4'-hexafluoroisopropyl bis(phthalic anhydride), stir, react for 24h, heat up to 162°C, add xylene, react for 6h, wash , dried to obtain a chain extender; 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane, 3,3',4,4'-hexafluoroisopropylbis(phthal Anhydride), the mass ratio of 1,3-diaminopropyltetramethyldisiloxane is 51:44:37;

[0054] (2) Preparation of modified polymer:

[0055] a. Preparation of Product A:

[0056] Take borax, mix it with deionized water, add dopamine hydrochloride in a nitrogen atmosphere, stir for 12 minutes, add sodium carbonate, adjust the system temperature to 3°C, add methacryloyl chloride, keep the temperature, stir for 11 minutes, return to room temperature, and react 18h, extraction and drying to obtain product A; the molar ...

Embodiment 3

[0066] (1) Preparation of chain extender:

[0067] Take N,N-dimethylacetamide, in a nitrogen atmosphere, add 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane, 1,3-diaminopropyltetramethyldi Siloxane, stir for 15min, add 3,3',4,4'-hexafluoroisopropyl bis(phthalic anhydride), stir, react for 25h, heat up to 165°C, add xylene, react for 7h, wash , dried to obtain a chain extender; 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane, 3,3',4,4'-hexafluoroisopropylbis(phthal Anhydride), the mass ratio of 1,3-diaminopropyltetramethyldisiloxane is 52:45:50;

[0068] (2) Preparation of modified polymer:

[0069] a. Preparation of Product A:

[0070] Take borax, mix it with deionized water, add dopamine hydrochloride in a nitrogen atmosphere, stir for 15 minutes, add sodium carbonate, adjust the system temperature to 0°C, add methacryloyl chloride, keep the temperature, stir for 12 minutes, return to room temperature, and react 24h, extraction and drying to obtain product A; the molar ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap