Novel epoxy resin and application thereof

An epoxy resin, a new type of technology, applied in the direction of organic material conductors, non-metallic conductors, etc., can solve problems such as poor corrosion resistance, device performance degradation, limiting the service life of the engine or the environment in which tasks are performed, and achieve breakthroughs in technical bottlenecks, The effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

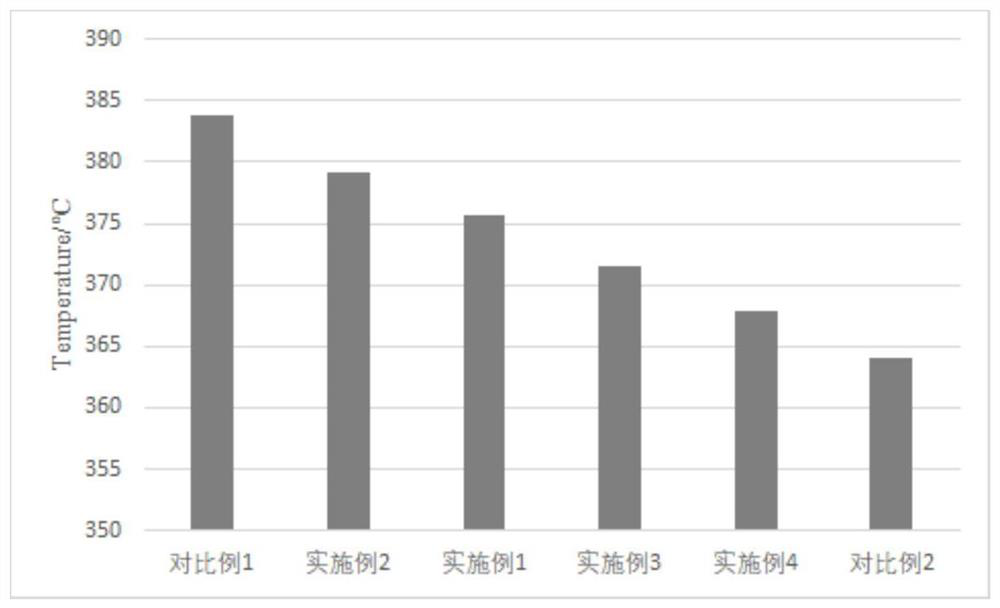

[0035] The novel epoxy resin described in Example 1 includes the following raw materials in parts by weight: 0.15 parts by weight of carboxyl-containing imide curing agent, 0.04 parts by weight of diethylenetriamine, and 1.25 parts by weight of bisphenol-A epoxy resin.

[0036] The preparation method of described novel epoxy resin comprises the following steps:

[0037] (1) Preparation of carboxyl-containing imide curing agent: adding trimellitic anhydride to m-cresol, stirring until completely dissolved under heating conditions at a temperature of 150° C., adding diaminodiphenyl ether to the solution, the trimellitic anhydride and The molar ratio of diaminodiphenyl ether is 2:1, react at a temperature of 150°C for 6 hours, and after the reaction is completed, the reaction product is quenched with ice water, vacuum filtered and washed in sequence, and the detergent used is methane A mixture of cresol and water;

[0038] Then vacuum-dry the obtained washings at a temperature o...

Embodiment 2

[0041] The novel epoxy resin described in Example 2 includes the following raw materials in parts by weight: 0.2 parts by weight of carboxyl-containing imide curing agent, 0.04 parts by weight of diethylenetriamine, and 1.25 parts by weight of bisphenol-A epoxy resin.

[0042] The preparation method of novel epoxy resin described in embodiment 2 is identical with the preparation method of novel epoxy resin described in embodiment 1.

Embodiment 3

[0044] The novel epoxy resin described in Example 3 includes the following raw materials in parts by weight: 0.1 parts by weight of carboxyl-containing imide curing agent, 0.06 parts by weight of diethylenetriamine, and 1.25 parts by weight of bisphenol-a epoxy resin.

[0045] The preparation method of novel epoxy resin described in embodiment 3 is identical with the preparation method of novel epoxy resin described in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com