Aminated graphene water-based heat dissipation coating as well as preparation method and application thereof

A heat-dissipating coating and amination technology, applied in the direction of coating, can solve the problem of not significantly improving the thermal conductivity of composite materials, and achieve the effects of coating stability, improving heat-dissipating performance and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

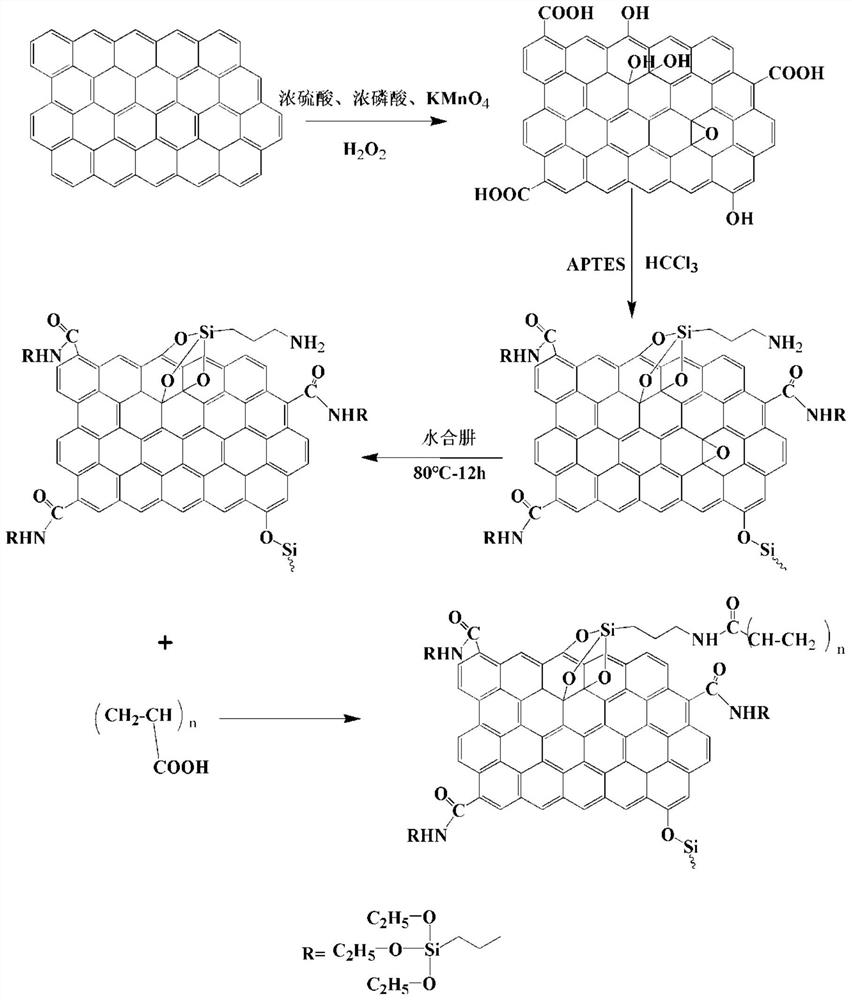

[0063] Such as figure 1 Shown, the invention provides a kind of preparation method of aminated graphene water-based heat dissipation coating, it may further comprise the steps:

[0064] Preparation of S1 graphene dispersion slurry

[0065] 1) Preparation of modified graphene

[0066] Graphene oxide preparation: fluffy flake graphite and concentrated sulfuric acid (concentration is 98wt%), concentrated phosphoric acid (concentration is 85wt%), KMnO 4 (The ratio of the four is (1g): (110-120ml): (13-15ml): (5.8-6ml), preferably (1g): (112.5ml): (13.5ml): (6g), preferably after Graphene oxide has the least number of layers and the number of oxygen-containing functional groups) is placed in an ultrasonic water bath and reacted under mechanical stirring. After the reaction is completed, the unreacted oxides are reduced with hydrogen peroxide, and then centrifuged with hydrochloric acid and deionized water. Wash until the pH is 6.5-7, then wash with absolute ethanol, and dry the ...

Embodiment 1

[0087] The present embodiment provides a kind of preparation method of aminated graphene water-based heat-dissipating coating, comprising the following steps:

[0088] (1) Preparation of graphene dispersion slurry

[0089] 1) Preparation of modified graphene

[0090] The preparation of graphene oxide (GO) adopts the improved Hummers method. The detailed synthesis process is as follows: add 4g flake graphite to a three-neck flask equipped with a stirring device, turn on the mechanical stirring (700rpm), and slowly add 450mL concentrated sulfuric acid (concentration: 98wt %) and 54mL concentrated phosphoric acid (concentration is 85wt%), then slowly add 24g KMnO in the there-necked flask 4 , the temperature of the ultrasonic water bath should be adjusted in time (concentrated sulfuric acid and potassium permanganate are added to release heat and increase the temperature of the system). ) was turned on and reacted for 12 hours. When the system cools down to room temperature af...

Embodiment 2

[0102] The difference between this embodiment and embodiment 1 is that the addition amount of the graphene dispersion slurry is different, and the remaining steps and parameters are the same as in embodiment 1. A kind of preparation method of aminated graphene water-based heat-dissipating coating of the present embodiment, comprises the following steps:

[0103] (1) Graphene dispersion slurry is identical with embodiment 1.

[0104] (2) Preparation of graphene heat dissipation coating

[0105] Weigh 25g graphene dispersion slurry, 57.5g 789 resin, 2g deionized water, 1g defoamer BYK-028, 1g leveling agent BYK-381, 1g film forming agent dodecyl alcohol ester, 1g adhesion promoter 11.5g of water-based amino resin was added into the dispersion tank, and dispersed and stirred for 3h at a rotating speed of 1500rpm to obtain a water-based graphene heat-dissipating coating with a viscosity of 650mPa·s.

[0106] Before spraying, pre-treat the aluminum surface of the heating plate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com