Low dielectric constant bonding sheet containing hollow ceramic powder and preparation method thereof

A low dielectric constant, bonding sheet technology, used in film/sheet adhesives, adhesives, devices for coating liquids on surfaces, etc., can solve problems affecting the consistency and stability of high-frequency circuit signal transmission, Warp and weft weaving density difference and other issues, to achieve the effect of benefiting stability and consistency, stabilizing bond strength, and avoiding glass fiber effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

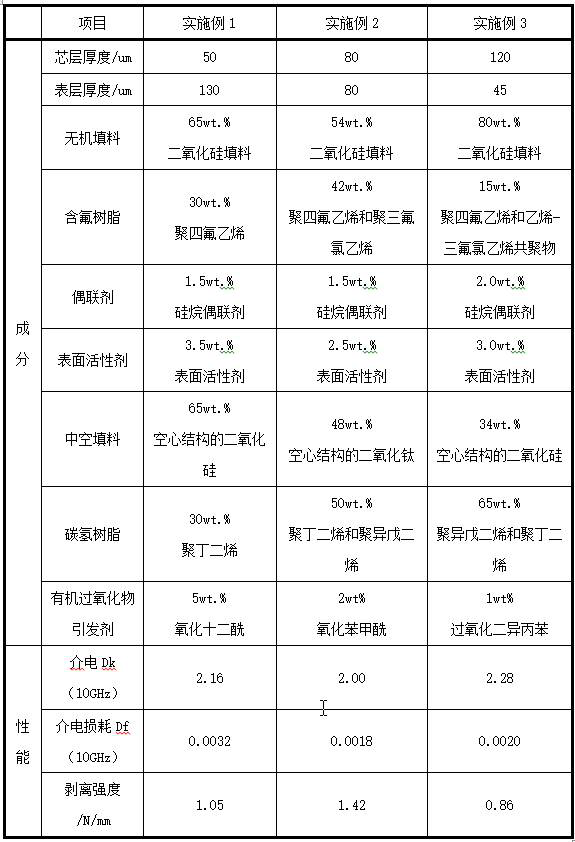

[0035] A low dielectric constant bonding sheet containing hollow ceramic powder, the bonding sheet includes a core layer, an upper surface layer and a lower surface layer, wherein the thickness of the core layer is 55um; the thickness of the upper surface layer and the lower surface layer are both 130um.

[0036] The core layer of the bonding sheet is composed of the following raw materials in mass percentage:

[0037] 65wt.% silica filler, 30wt.% polytetrafluoroethylene, 1.5wt.% silane coupling agent, 3.5wt.% surfactant.

[0038] The surface layer of the bonding sheet is composed of the following raw materials in mass percentage:

[0039] 65wt.% hollow silica, 30wt.% polybutadiene, 5wt.% lauryl oxide.

[0040] A method for preparing a low dielectric constant bonded sheet comprising hollow ceramic powder, the steps are as follows:

[0041] Core layer preparation process:

[0042] Step 1: Mix the surfactant with deionized water, stir at 50r / min for 15min, then add coupling a...

Embodiment 2

[0049] A low dielectric constant bonding sheet containing hollow ceramic powder, the bonding sheet includes a core layer, an upper surface layer and a lower surface layer, wherein the thickness of the core layer is 80um; the thickness of the upper surface layer and the lower surface layer are both 80um.

[0050] The core layer of the bonding sheet is composed of the following raw materials in mass percentage:

[0051]54wt.% silica filler, 42wt.% polytetrafluoroethylene and polychlorotrifluoroethylene, 1.5wt.% silane coupling agent, 2.5wt.% surfactant.

[0052] The surface layer of the bonding sheet is composed of the following raw materials in mass percentage:

[0053] 48wt.% titanium dioxide with hollow structure, 50wt.% polybutadiene and polyisoprene, 2wt% benzoyl oxide.

[0054] A method for preparing a low dielectric constant bonded sheet comprising hollow ceramic powder, the steps are as follows:

[0055] Core layer preparation process:

[0056] Step 1: Mix the surfact...

Embodiment 3

[0063] A low dielectric constant bonding sheet containing hollow ceramic powder, the bonding sheet includes a core layer, an upper surface layer and a lower surface layer, wherein the thickness of the core layer is 120um; the thickness of the upper surface layer and the lower surface layer are both 45um.

[0064] The core layer of the bonding sheet is composed of the following raw materials in mass percentage:

[0065] 80wt.% silica filler, 15wt.% polytetrafluoroethylene and ethylene-chlorotrifluoroethylene copolymer, 2.0wt.% silane coupling agent, 3.0wt.% surfactant.

[0066] The surface layer of the bonding sheet is composed of the following raw materials in mass percentage:

[0067] 34wt.% hollow structure silica, 65wt.% polyisoprene and polybutadiene, 1wt% dicumyl peroxide.

[0068] A method for preparing a low dielectric constant bonded sheet comprising hollow ceramic powder, the steps are as follows:

[0069] Core layer preparation process:

[0070] Step 1: Mix the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap