Application of mixed fermentation product of Penicillium commune and Lactobacillus reuteri in relieving successive cropping obstacles of apples

A common penicillium and fermentation product technology, applied in the field of agricultural microorganisms, can solve the problems such as no apple continuous cropping obstacles, and achieve the effect of increasing the number of cultivable bacteria, reducing the content, and improving the structure of soil microbial communities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

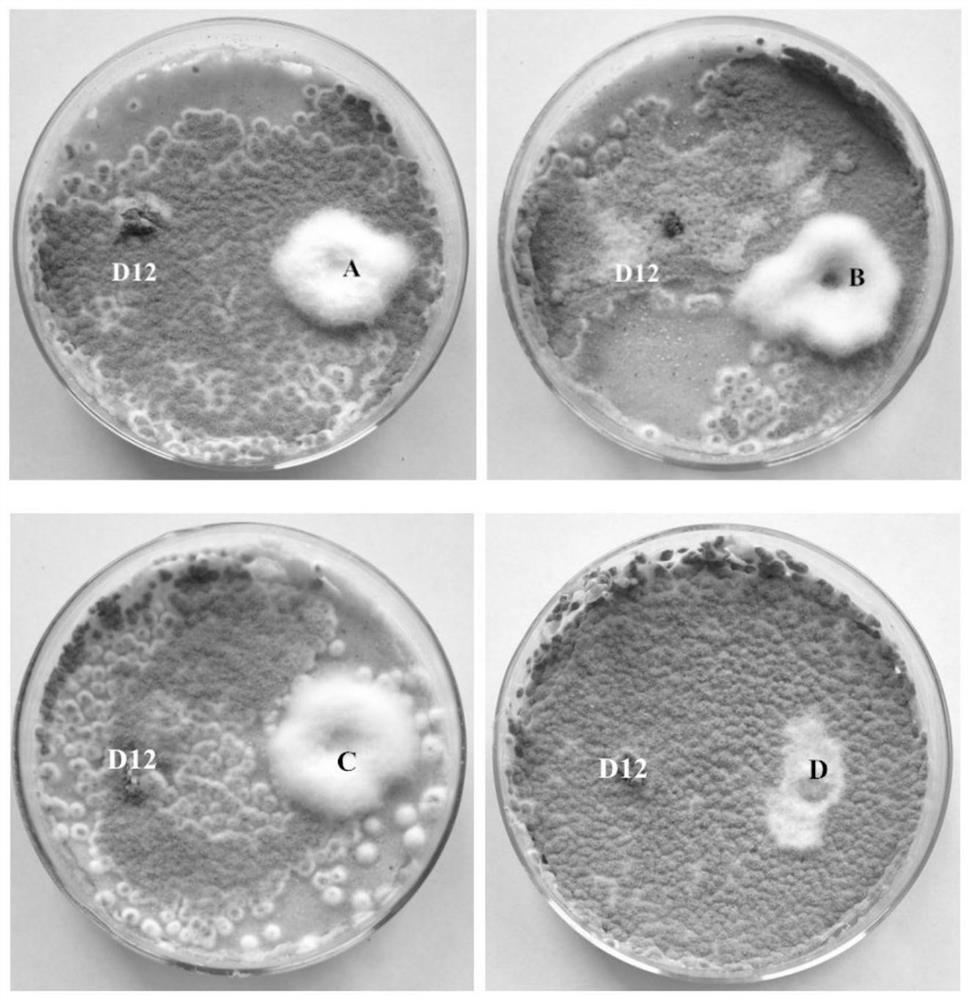

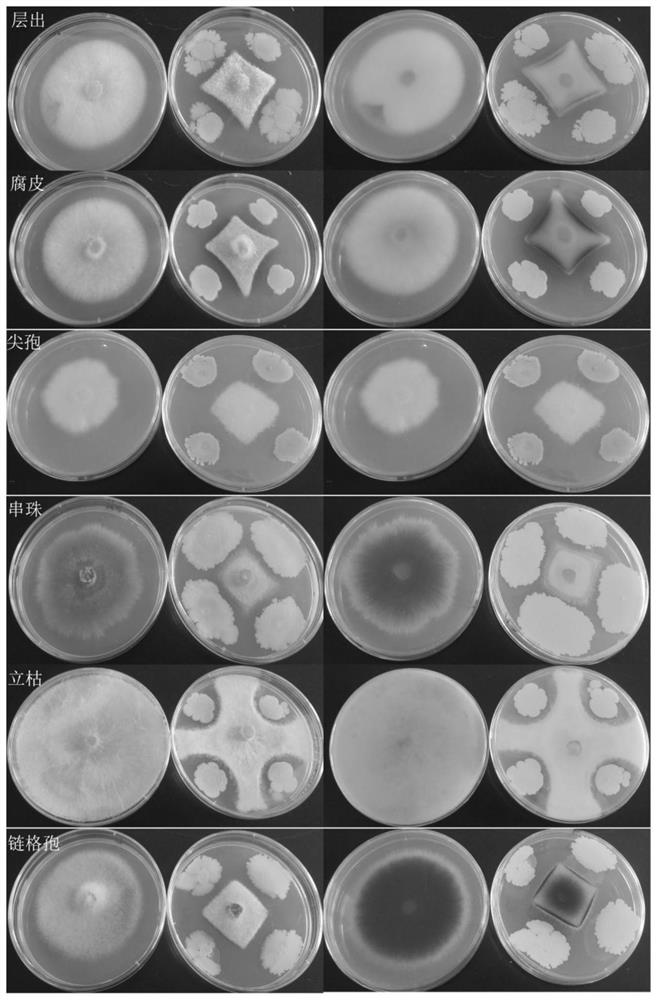

[0041] Example 1: Preparation of Penicillium vulgaris D12 fermentation product and identification of volatile components

[0042] Penicillium vulgaris D12 was isolated from the soil where sweet potatoes were grown, and it was biologically preserved. The biological preservation information is as follows:

[0043] Preservation time: July 14, 2015;

[0044] Collection Center: General Microbiology Center of China Microbiological Culture Collection Management Committee;

[0045] Deposit number: CGMCC No.11112.

[0046] 1. Preparation of Penicillium vulgaris D12 fermentation product

[0047] (1) Plate activation strain

[0048] Pick D12 mycelia on PDA solid medium and culture at 27°C for 5 days.

[0049] (2) Preparation of seed solution

[0050] Add 500mL of PDA liquid medium to a 1L Erlenmeyer flask, wrap the mouth with parafilm or gauze, and sterilize at 121°C for 20min. After cooling down to room temperature, the plate mycelium was picked and cultured on a rotary shaker in ...

Embodiment 2

[0063] Embodiment 2: Preparation and component identification of Lactobacillus reuteri fermentation product

[0064] 1. Preparation of Lactobacillus reuteri fermentation product

[0065] Lactobacillus reuteri (Lactobacillus reuteri) purchased from the China Industrial Microbiology Culture Collection Management Center (No. CICC 6118) was activated and inserted into the improved MRS medium, and cultured at 37°C for 5 days to obtain Lactobacillus reuteri Fermentation liquid: Lactobacillus reuteri fermentation liquid was mixed until there was no sediment, centrifuged at 8000r / min for 10min, and the fermentation product of Lactobacillus reuteri was obtained.

[0066] 2. Identification of components of fermentation products of Lactobacillus reuteri

[0067] Volatile organic compounds were determined by GC-MS, and 1 L of fermentation product was centrifuged at 12000 r / min for 5 min. The supernatant was extracted 3 times with 1L ethyl acetate, and the extracts were combined 3 times....

Embodiment 3

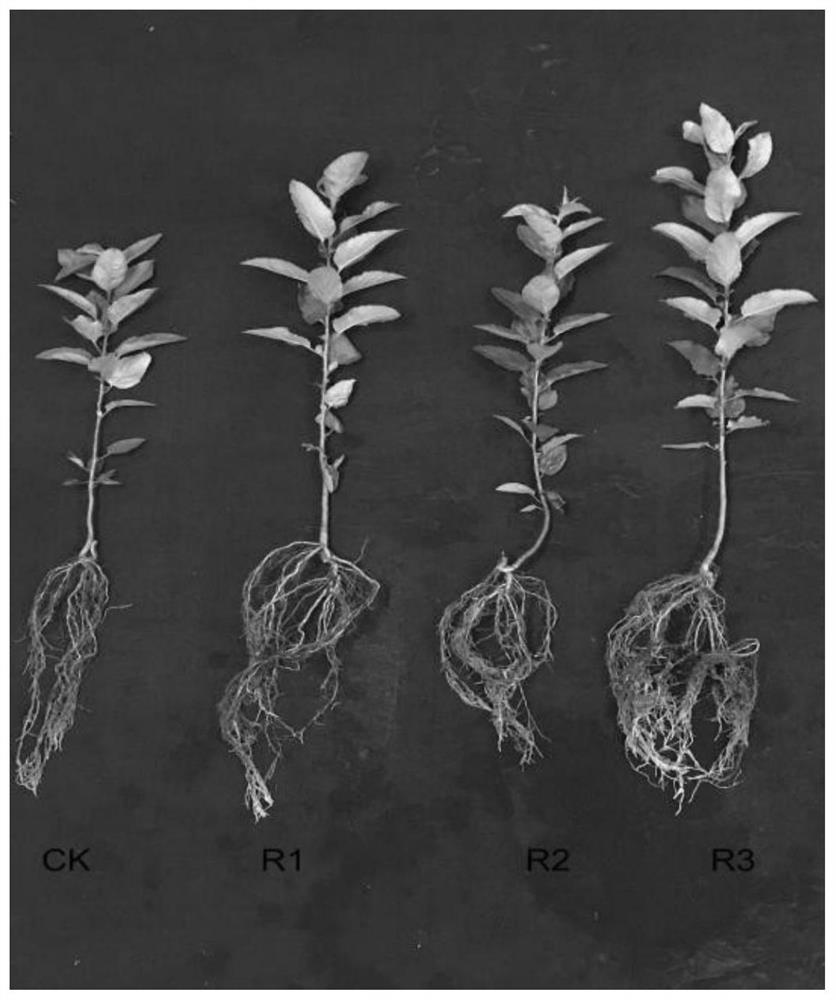

[0073] Embodiment 3: pot test

[0074] 1. Experimental design:

[0075] The pot experiment was carried out at the National Apple Engineering Experiment Center and the Apple Replanting and Microbiology Laboratory on the South Campus of Shandong Agricultural University from January to October 2019. The soil used in the pot experiment was taken from a 32-year-old Fuji apple orchard in Manzhuang Town, Tai'an City, Shandong Province. From the area 80 cm away from the trunk of the apple tree and 10-40 cm deep, soil was randomly collected from multiple points and mixed. The soil type is sandy soil, and the organic matter content is about 8.3g·kg -1 , the nitrate nitrogen content is about 11.76mg·kg -1 , the content of ammonium nitrogen is about 5.76mg·kg -1 , the content of available potassium is about 116.64mg·kg -1 , the content of available phosphorus is about 10.42mg·kg -1 , soil pH 5.66.

[0076] Pingyi sweet tea (Malus hupehensis Rehd.) is a commonly used rootstock variet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com