Instant pandan powder and preparation method thereof

A technology of instant powder and pandan, which is applied in food science, food preservation, and the function of food ingredients, etc. It can solve the problems of low yield of freeze-dried powder, limited application of pandan leaves, and poor powder solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

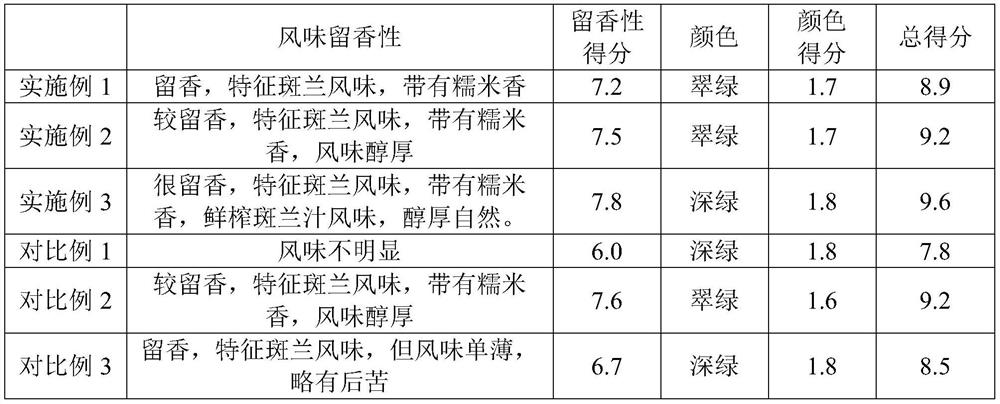

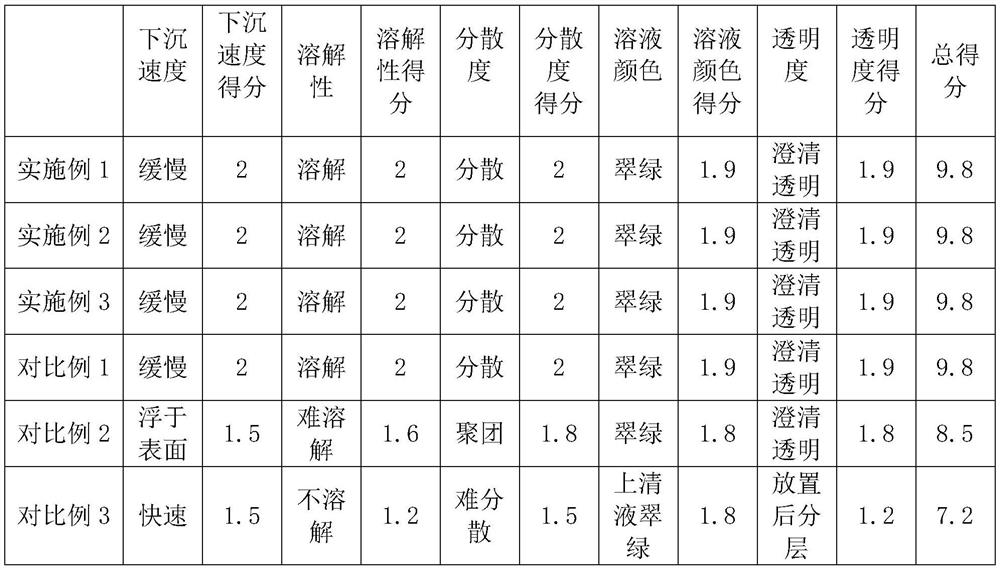

Examples

preparation example Construction

[0078] Some embodiments of the present invention, a method of preparing a tapping spot Miniature comprises the steps of:

[0079] S100: The fresh leaves pandan 30 ℃ ~ 50 ℃ dried, crushed to 40 to 60 mesh to prepare pandan leaf powder;

[0080] S200: The blue plaques leaf powder and 50% to 70% aqueous ethanol mixed to prepare a mixture obtained pandan leaf, wherein the mass amount of the aqueous ethanol is 1 to 3 times the mass of powder blue leaf spot;

[0081] S300: In the presence of celite, the mixture was extracted with pandan leaves at a temperature of 30 ℃ ~ 50 ℃ performs 2h, 0.5h ~ separated and extracted at a temperature of 40 ℃ ~ 50 ℃ extracted under pressure conditions of 10MPa ~ 20MPa were separated under separating conditions 5MPa ~ 10MPa pressure, the liquid phase was collected to give a tapping spot Miniature, wherein the particle size of the diatomaceous earth is 60 to 80 mesh.

[0082] Wherein, for the step S100 pandan leaf powder to prepare a particular size, step...

Embodiment 1

[0146] 1.1 Ingredients

[0147] Leaf spot using blue plaques were prepared 10kg Miniature extracting solution, freshly squeezed juice blue spots. 40 parts by mass were weighed spots Miniature extracting solution, 1.2 parts by mass of vanilla extract, 1 part by mass green tea extract, 1 part by mass of citric acid, 0.1 parts by mass of vitamin C, 160 parts by mass of fresh plaque Lan juice and 160 parts by mass of the maltodextrin and heated to 40 ℃, evenly stirred and mixed to obtain a mixture, the standby.

[0148] 1.2 drying

[0149] Dynamic vacuum drying (MJY60-6) The above mixture was dried at 100 deg.] C 5min, cooled to 70 deg.] C and then dried 7min, then cooled to 22 ℃ drying 12min, the total drying time was 24min, dried with walking speed of 0.2m / min, followed by pulverization, to obtain a particle size of 20 blue plaques object 6kg instant powder, 60% overall yield.

Embodiment 2

[0151] Example 1 using substantially the same method pandan instant powder, except that: 60 parts by mass were weighed spots Miniature extracting solution, 1 part by mass of vanilla extract, 2 parts by mass of the green tea extract, 1 parts by mass of citric acid, 0.2 parts by mass of vitamin C, 180 parts by mass of freshly squeezed juice and blue spots 180 parts by mass maltodextrin, other parameters the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com