Device for producing biodiesel through continuous ester interchange

A technology of biodiesel and transesterification, applied in biofuel, fat production, petroleum industry, etc., can solve the problems that the acid value of the product is difficult to meet the national standard, the reaction time of the biological enzyme method is long, and the level of automatic control is low, so as to realize the process The effect of automation control level, improvement of process automation control level, equipment utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The device for producing biodiesel by continuous transesterification of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

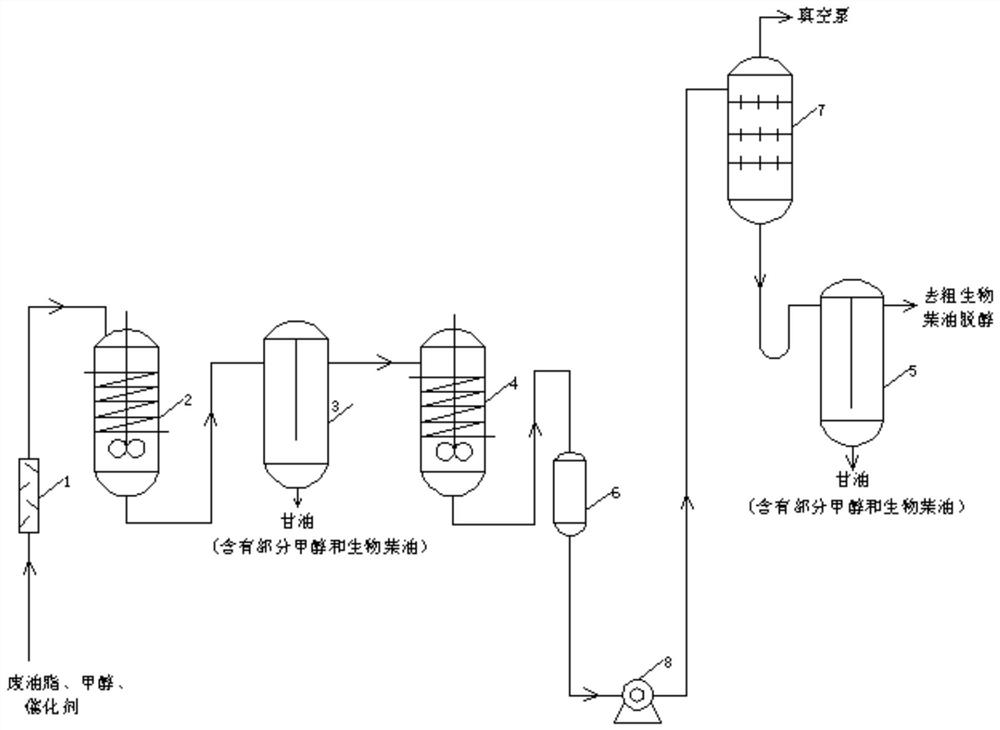

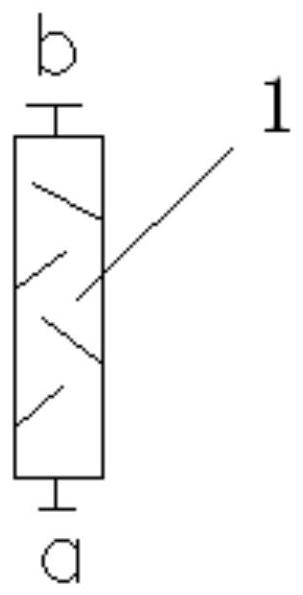

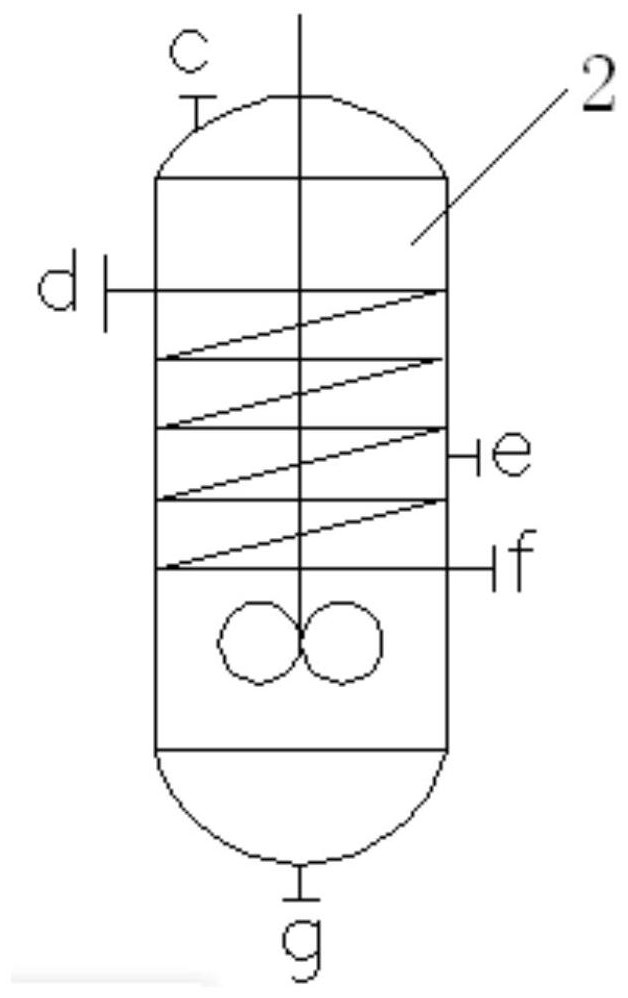

[0022] Figure 1-Figure 8 As shown, the device for producing biodiesel by continuous transesterification of the present invention includes a static mixer 1, a No. 1 reactor 2, a No. 1 precipitation tank 3, a No. 2 reactor 4, a No. 2 precipitation tank 5, a buffer tank 6, and a flash evaporator 7 and pump 8; the static mixer 1 is provided with a mixer feed port a and a mixer discharge port b, and the mixer is a spiral channel to mix waste grease, methanol, and catalyst evenly, and the mixer discharge port b It is connected with the feed port c of the No. 1 reactor; the No. 1 reactor 2 is also provided with the outlet g of the No. 1 reactor, the steam inlet d of the No. 1 reactor, the condensed water outlet f of the No. 1 reactor, and the No. 1 reactor The temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com