Keratinase and application

A technology of keratinase and crude enzyme liquid, applied in the field of protease, can solve the problems of secondary pollution waste, difficult to handle, and less industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The keratinase LbKer mentioned in the present invention has the amino acid sequence shown in the sequence table SEQ ID NO.1, and the keratinase LbKer is derived from Lysobacter sp., which was preserved in China Microorganisms on July 09, 2018 Center for General Microbiology of the Preservation Committee.

[0026] The substrate spectrum of the provided keratinase of the present invention:

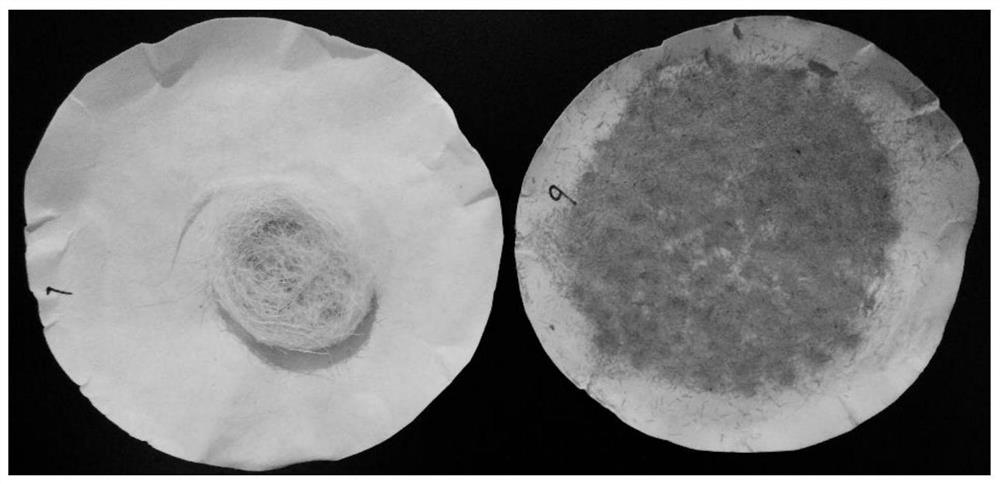

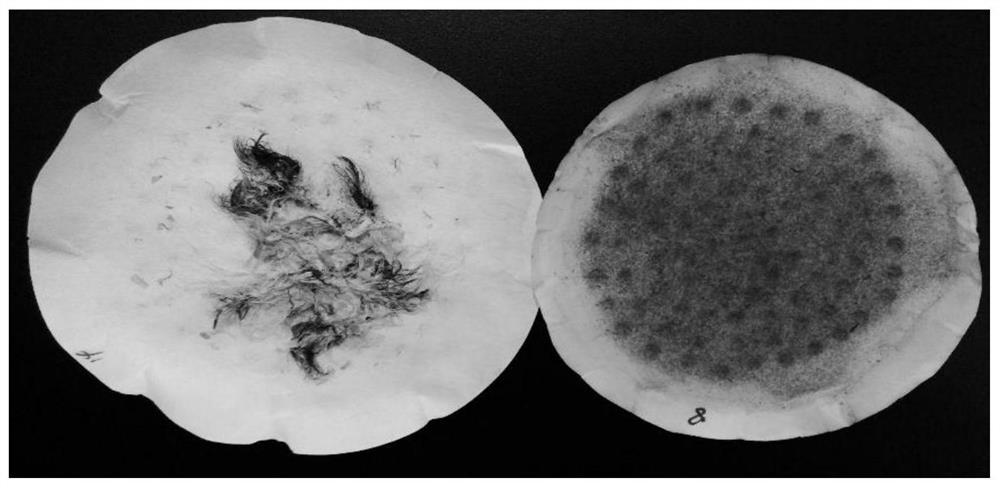

[0027] The action substrate spectrum of LbKer has been studied in embodiment 1, select chicken feather, duck feather, goose feather, wool, cow hair and hoof horn as substrate, add 5mL LbKer crude enzyme liquid in 0.1g substrate solution, under stirring, let mixture The reaction was carried out at 45°C and pH 8.0 for 12 hours. Then the sample was boiled for 1 minute to inactivate the enzyme, and the degradation ability of different substrates was characterized by filtering and weighing the residual insoluble matter.

[0028] The results are shown in Table 1, LbKer has relatively high...

Embodiment 2

[0037] Regarding the enzymatic properties of the keratinases of the present invention

[0038] (1) In order to determine the optimal reaction temperature of the enzyme, the enzyme was reacted at different temperatures (30-80°C) and pH 7.5 for 60 minutes to detect the enzyme activity;

[0039] (2) In order to study the temperature stability of the enzyme, the enzyme was pre-incubated at different temperatures (30-80°C) for 30 minutes, pH 7.5, and reacted at 37°C for 60 minutes to detect the remaining enzyme activity of the enzyme;

[0040] (3) In order to determine the optimal pH value, the enzyme activity of the enzyme was measured for 60 minutes at 37°C under different pH conditions;

[0041] (4) In order to study the pH value stability of the enzyme, the enzyme was pre-incubated overnight in various pH5-12 buffers, and then reacted at pH7.5, 37°C for 60 minutes to detect the remaining enzyme activity;

[0042] The detection of the above enzymatic characteristics is to use k...

Embodiment 3

[0052] Application of LbKer 1

[0053] Weigh 1g of dried wool and add 50mL keratinase LbKer crude enzyme solution to react at 37°C for 12h, filter and wash the reaction solution with neutral filter paper, dry the residue to constant weight and weigh, calculate the degradation rate, wool degradation rate Reached 76.9%.

[0054] Application of LbKer 2

[0055]Weigh 0.5g of dried chicken feathers and add 25mL keratinase LbKer crude enzyme solution to react at 37°C for 12h, filter and wash the reaction solution with neutral filter paper, dry the residue to constant weight and weigh, calculate the degradation rate, chicken feather degradation The rate reached 84.1%.

[0056] Application of LbKer 3

[0057] Weigh 1g of dried hoof horn and add 50mL keratinase LbKer crude enzyme solution to react at 37°C for 12h, filter and wash the reaction solution with neutral filter paper, dry the residue to constant weight and weigh, calculate the degradation rate, hoof angle The degradation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com