Method for separating uranium and neptunium through fluorination volatilization technology

A technology, fluorination technology, applied in the field of fluorination volatilization separation of uranium and neptunium, can solve the problems of complicated operation, high requirement of extraction agent, inability to achieve continuous operation, etc., and achieve high separation efficiency, stable properties and easy continuous operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

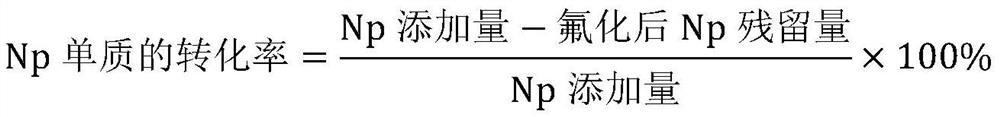

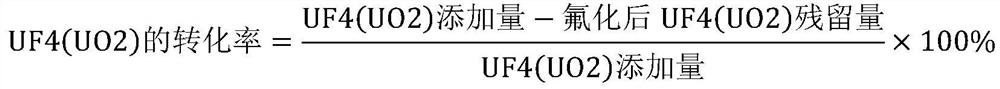

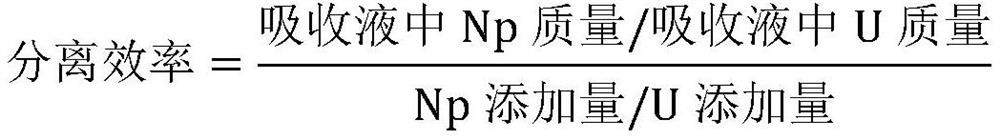

[0076] Example 1UF 4 Separation of uranium and neptunium in a mixture with Np

[0077] (1) 5.0g UF 4 and 1 mg neptunium elemental mixture, placed in the reactor, cover the reactor lid, and replace the atmosphere in the reactor with high-purity argon.

[0078] (2) Heating the reactor to raise the temperature from room temperature to 450°C, keep it warm for 2 hours, and feed nitrogen trifluoride and argon mixed gas (NF 3 The volume fraction is 20%), the flow rate is 0.3L / min, adopt Fourier transform infrared spectrometer to monitor the reactor outlet gas; adopt two-stage NaF adsorption column to reclaim UF 6 product, the temperature of the adsorption column is 100°C; after 60min, UF in the gas at the outlet of the reactor 6 When the concentration is lower than the lower limit of infrared detection, stop passing nitrogen trifluoride mixed gas at this time.

[0079] (3) After stopping the heating of the reactor to lower the temperature to 350°C, keep it warm for 1h, and feed t...

Embodiment 2

[0081] Embodiment 2UO 2 Separation of uranium and neptunium in a mixture with Np

[0082] (1) Add 3.0g UO 2 The mixture of 1 mg neptunium and elemental neptunium is placed in the reactor, the reactor lid is covered, and the atmosphere in the reactor is replaced with high-purity argon.

[0083] (2) Heating the reactor to raise the temperature from room temperature to 500°C, keep it warm for 1h, and pass a mixed gas of nitrogen trifluoride and argon (NF 3 The volume fraction is 30%), the flow rate is 0.2L / min, adopt Fourier transform infrared spectrometer to monitor the reactor outlet gas; adopt two-stage cold trap to reclaim UF 6 products, the condensing temperature is -40°C; after 120min, UF in the reactor outlet gas 6 When the concentration is lower than the lower limit of infrared detection, stop passing nitrogen trifluoride mixed gas at this time.

[0084] (3) After stopping the heating of the reactor to lower the temperature to 350°C, keep it warm for 1h, and feed the ...

Embodiment 3

[0086] Example 3LiF-BeF 2 Separation of Uranium and Neptunium in Molten Salt System

[0087] (1) 100g LiF-BeF 2 Molten salt (of which UF 4 Mass 5.0g, Np mass 0.5mg; LiF and BeF in eutectic salt 2 The molar ratio is 67:33) placed in the reactor, cover the reactor lid, and replace the atmosphere in the reactor with high-purity argon.

[0088] (2) Heating the reactor to raise the temperature from room temperature to 700°C, keep the temperature for 3 hours, and feed nitrogen trifluoride and argon mixed gas (NF 3 The volume fraction is 10%), the flow rate is 0.5L / min, adopt Fourier transform infrared spectrometer to monitor the reactor outlet gas; adopt two-stage NaF adsorption column to reclaim UF 6 product, the temperature of the adsorption column is 100°C; after 60min, UF in the gas at the outlet of the reactor 6 When the concentration is lower than the lower limit of infrared detection, stop passing nitrogen trifluoride mixed gas at this time.

[0089] (3) After stopping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com