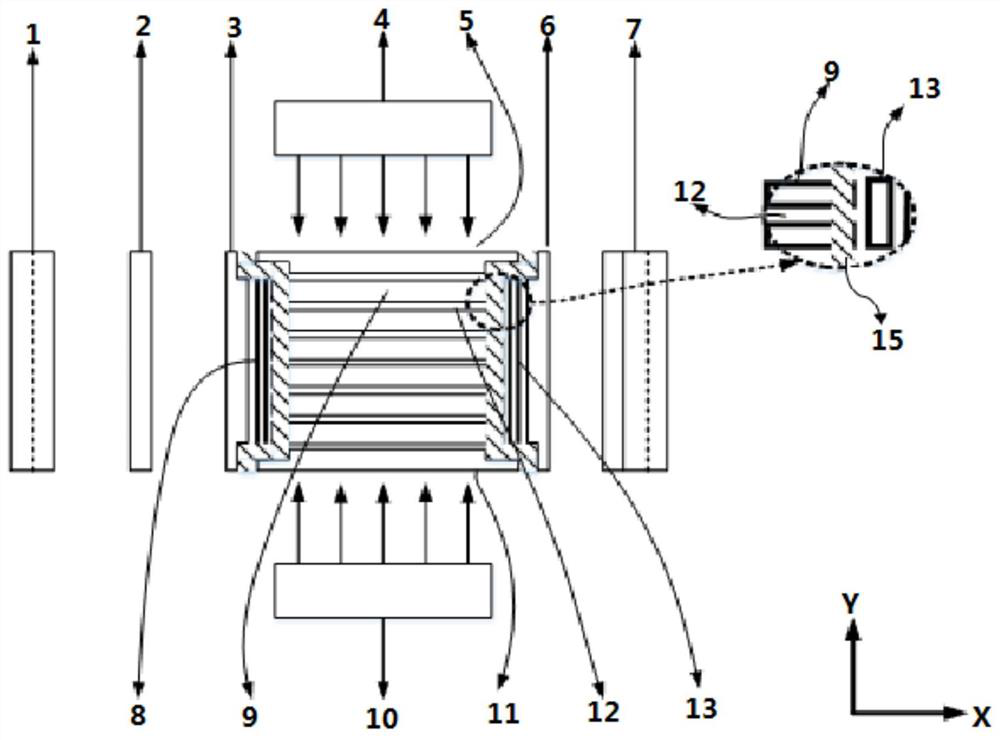

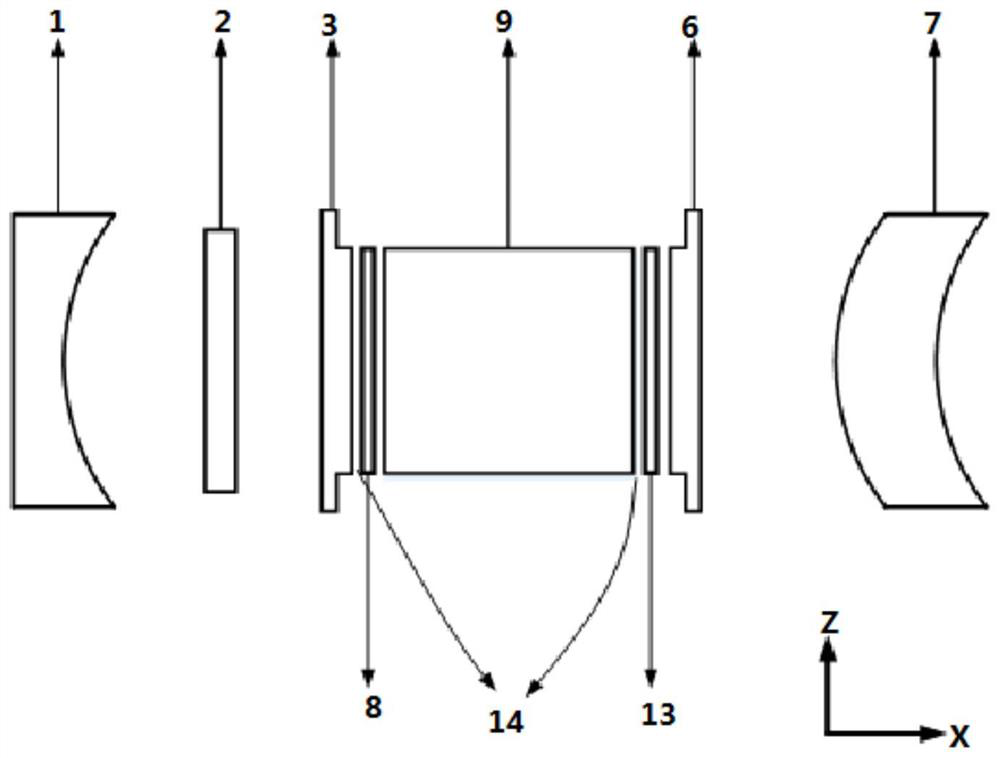

High-power liquid cooling pulse solid laser device

A pulsed solid and liquid cooling technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of poor output laser beam quality, larger volume and complexity of laser systems, and limited practicality of lasers. To achieve the effect of sufficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The laser gain medium uses Nd:YAG crystal, and the saturable absorber uses Cr 4+ :YAG ceramics, heavy water is used as cooling liquid, because the size of ceramics can be made very large in theory, and it will not cause uneven doping ion concentration due to the increase in size like crystals, so Cr 4+ As a saturable absorber, YAG ceramics can increase the laser output power by increasing the number of parallel gain media and the size of the saturable absorber. Both the laser gain medium cooling liquid and the saturable absorber cooling liquid use heavy water. The absorption coefficient of the pump light wavelength is very small, which can reduce the loss in the resonant cavity. In the present invention, the laser can output 1064nm pulsed laser with high average power, high peak power and high beam quality, and can increase the parallel Nd:YAG The number of crystals increases the average power of the output 1064nm pulsed laser.

Embodiment 2

[0028] The laser gain medium uses Nd:YAG crystal, and the saturable absorber uses V 3+ : YAG ceramics, the cooling liquid adopts heavy water, the laser can output 1.3um pulsed laser with high average power, high peak power and high beam quality in the present invention, and the 1.3um pulsed laser output can be increased by increasing the number of parallel Nd:YAG crystals average power.

Embodiment 3

[0030] The laser gain medium adopts Yb:YAG crystal, and the saturable absorber adopts Cr 4+ :YAG ceramics, heavy water is used as cooling liquid, Yb:YAG crystal is pumped by 940nm or 976nm pump source, and the output laser wavelength is 1030nm, which has higher quantum efficiency than Nd:YAG crystal. The heat is smaller and the light-to-light conversion efficiency is higher. In the present invention, the laser can output 1030nm pulse laser with high average power, high peak power and high beam quality, and can increase the output 1030nm by increasing the number of parallel Yb:YAG crystals The average power of the pulsed laser.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com