High-water-solubility tylvalosin premix

A technology of tivallosin and water-solubility, which is applied in the field of highly water-soluble tivallosin premixes, can solve the problems of poor formulation stability, easy agglomeration, and difficulty in reaching high concentrations of solubility, and achieves a simple preparation process. , The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

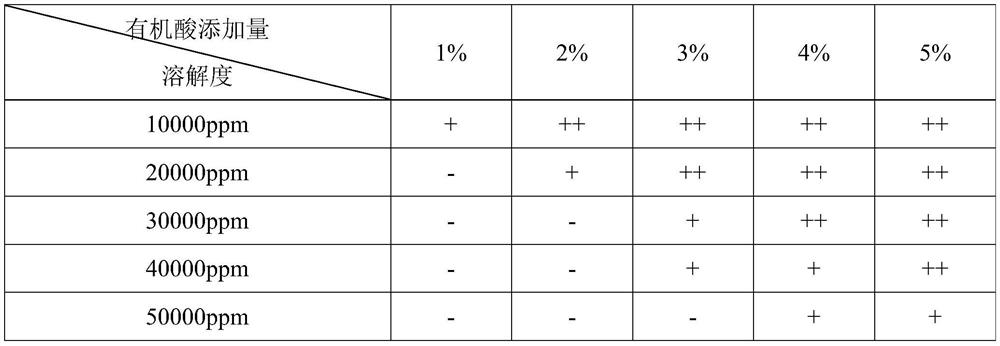

[0019] 1.1 Screening of the minimum addition amount of organic acid co-solvent

[0020] 1.1.1 There are three states after tyvalectin tartrate is dissolved in water: (1) completely clear and transparent, no visible precipitation at the bottom of the beaker after standing for 6 hours; (2) turbid and opaque, no visible precipitation at the bottom of the beaker after standing for 6 hours; (3) It is cloudy and opaque, and there is visible precipitation at the bottom of the beaker after standing for 6 hours.

[0021] 1.1.2 If the amount of organic acid co-solvent added is too high, it will affect the long-term stability of tyvanectin tartrate premix. Therefore, it is first necessary to test and verify the minimum addition amount of organic acid co-solvent.

[0022] According to preliminary tests, organic acids such as anhydrous DL-tartaric acid, succinic acid, anhydrous citric acid, DL-malic acid, etc., can significantly increase the solubility of tyvanectin tartrate. In the cour...

Embodiment 2

[0043] (1) Crush and sieve, crush anhydrous DL-tartaric acid and pass through an 80-mesh sieve, and set aside.

[0044] (2) The 20% tyvalactin tartrate premix formulation and specific consumption of the present embodiment are shown in Table 4 below

[0045] Table 4

[0046] Active ingredients Tivalamectin tartrate API 25.0kg Co-solvent Anhydrous DL-Tartrate 2.0kg pigment Caramel Coloring (Food Grade) 1.0kg filler Maltodextrin 72.0kg

[0047] (3) total mix

[0048] The four kinds of raw materials in the above-mentioned Table 4 were mixed, subpackaged and sealed to obtain 20% tivalamectin tartrate premix.

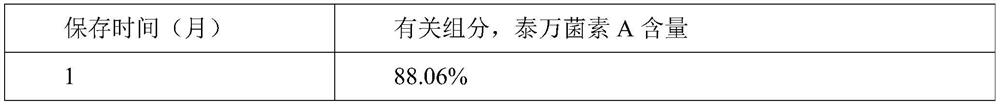

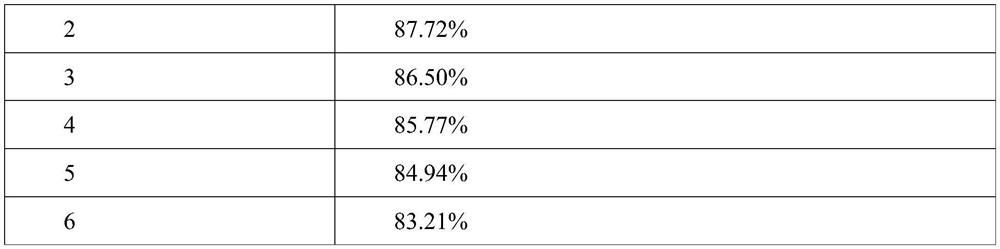

[0049] (4) Long-term stability accelerated test.

[0050] The subpackaged and sealed 20% tyvalactin tartrate premix was stored in a constant temperature and humidity chamber (40°C, 75% relative humidity) for 6 months, and the relevant components were tested once a month. The test results are shown in Table 5 below. According t...

Embodiment 3

[0054] (1) Crush and sieve: Crush anhydrous DL-tartaric acid and sucrose, pass through an 80-mesh sieve, and set aside.

[0055] (2) The 20% tyvalactin tartrate premix formulation and specific consumption of the present embodiment are shown in Table 6 below

[0056] Table 6

[0057] Active ingredients Tivalamectin tartrate API 25.0kg Co-solvent Anhydrous DL-Tartrate 2.0kg pigment Caramel Coloring (Food Grade) 1.0kg filler sucrose 72.0kg

[0058] (3) total mix

[0059] The four kinds of raw materials in the above-mentioned Table 6 were mixed, packaged and sealed to obtain 20% tyvalactin tartrate premix.

[0060](4) Long-term stability accelerated test.

[0061] The subpackaged and sealed 20% tyvalactin tartrate premix was stored in a constant temperature and humidity chamber (40°C, 75% relative humidity) for 6 months, and the relevant components were tested once a month. The test results are shown in Table 7 below. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com