Hydrate accelerant and method for continuously separating and capturing CO2

A hydrate accelerator, CO2 technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low growth rate, long nucleation time, energy consumption and high cost of separation and capture technology, and achieve The effect of accelerating diffusion rate, less dosage, and promoting rapid nucleation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

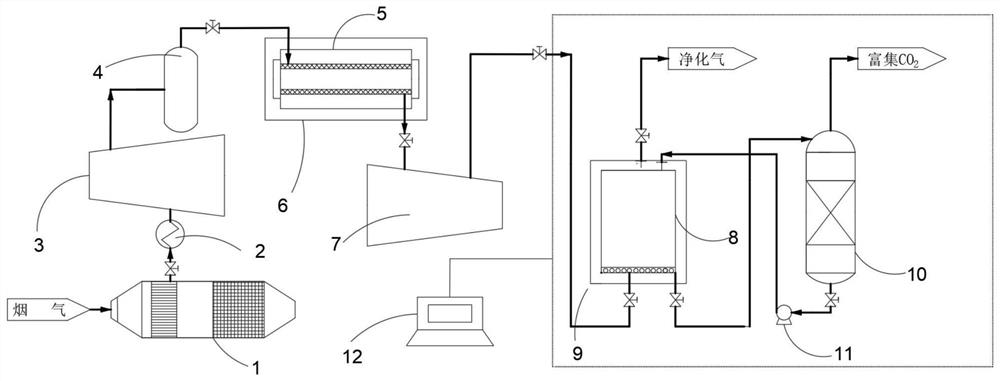

[0035] like figure 1 As shown, the embodiment of the present invention provides a CO 2 The method for separating and trapping comprises the steps of:

[0036] 1) CO 2 The mixed gas with a content of 5-10mol% is passed into the dust collector 1, and the large and fine particles of dust are filtered out. After the dust is removed, the mixed gas is cooled to 35°C by the condenser 2 and boosted to 0.5 by the gas booster pump-3. MPa, and stored in the gas storage tank 4;

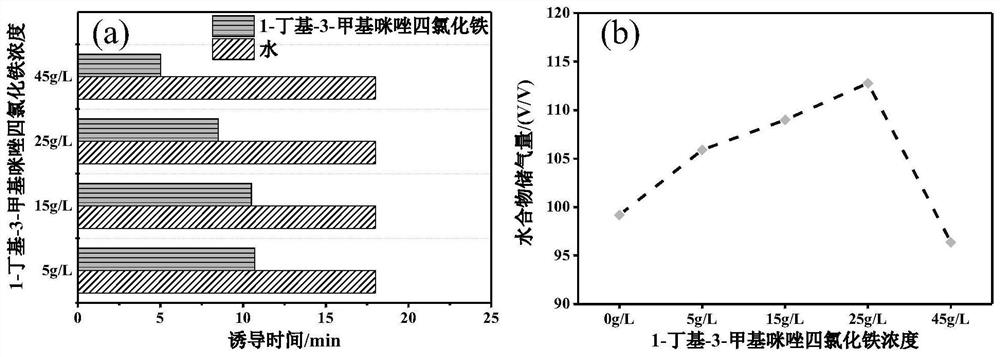

[0037] 2) The dust-removing mixed gas is preliminarily separated through the Pebax composite membrane separator 5, and the internal temperature of the membrane separator is stabilized at 15-35°C with the constant temperature tank 16, so that the CO in the mixed gas 2 Concentration reaches more than 50mol%, and then use liquid delivery pump 11 to continuously input the ionic liquid aqueous solution containing 1-butyl-3-methylimidazolium ferric tetrachloride into the bubbling hydration autoclave 8, so that the s...

Embodiment 2

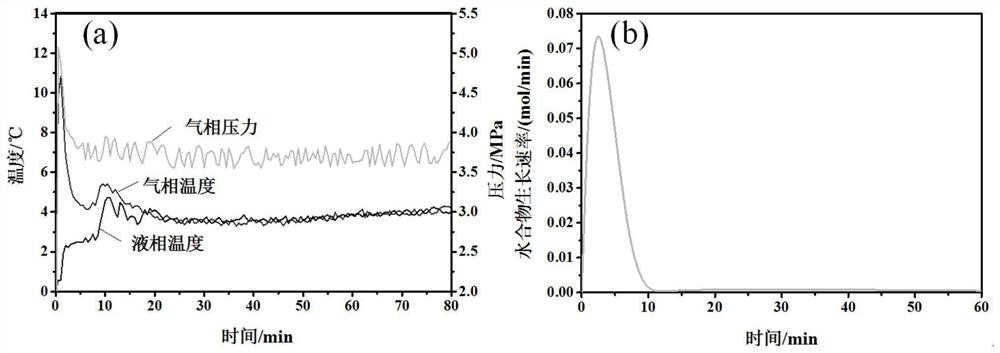

[0043] The difference between this embodiment 2 and embodiment 1 is that the CO 2 The hydration accelerator selects 25g / L 1-octyl-3-methylimidazolium ferric tetrachloride, such as image 3 (a), in CO 2 The rapid increase in liquid phase temperature during hydrate nucleation causes an increase in gas phase temperature, suggesting that CO 2 The nucleation of hydrates mainly occurs in the main body of the solution, such as image 3 As shown in (b), after hydrate nucleation, CO 2 The hydrate growth rate increased rapidly at first, reached the maximum within 5 minutes, and then gradually decreased.

[0044] In this example, CO 2 The induction time of hydrate nucleation is 7.8min, which is 56.7% lower than that of the pure water system, and the gas storage capacity reaches 110.4V / V, which is 10.1% higher than that of the pure water system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com