Catalyst for purifying dimethyl dichlorosilane as well as preparation method and application of catalyst

A technology of dimethyldichlorosilane and catalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of containing many by-products and affecting downstream Products and other issues, to achieve good dispersion, increase the reaction rate, improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

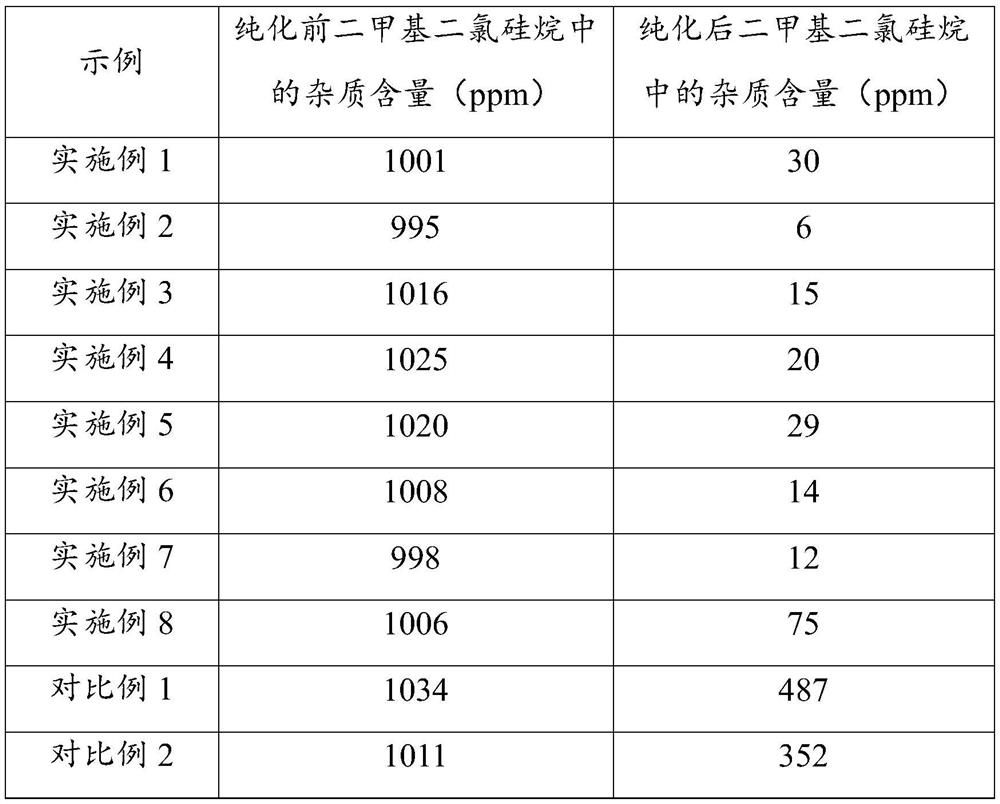

Examples

Embodiment 1

[0041] This comparative example provides a kind of catalyst that is used for purifying dimethyl dichlorosilane, and its raw material comprises TEOS, Pd(NO 3 ) 2 2H 2 O, AlCl 3 and H 2 O.

[0042] The preparation method of above-mentioned catalyst comprises the following steps,

[0043] At room temperature, the AlCl 3 , water and Pd(NO 3 ) 2 ·6H 2O Mix according to the above ratio and stir for 30 minutes. After the powder is completely dissolved, add TEOS and continue stirring for 20 minutes, then add triethylamine to adjust the pH to 9-10, continue stirring for 2 hours, then transfer the solution to a hydrothermal kettle, and crystallize at 200°C 48h;

[0044] Then the obtained crystallized product was cooled and filtered, washed three times with deionized water and ethanol, and dried at 100°C for 12 hours to obtain the original powder of molecular sieve loaded with palladium; then the original powder of molecular sieve was placed in a muffle furnace to Heat up to 60...

Embodiment 2

[0046] This embodiment provides a catalyst for purifying dimethyldichlorosilane, the raw material of which comprises orthoethyl silicate (TEOS), Pd(NO 3 ) 2 2H 2 O, Zn(NO 3 ) 2 ·6H 2 O, AlCl 3 and H 2 O.

[0047] The preparation method of above-mentioned catalyst comprises the following steps,

[0048] At room temperature, the AlCl 3 , deionized water, Pd(NO 3 ) 2 2H 2 O and Zn(NO 3 ) 2 ·6H 2 O mixed according to the above ratio, stirred for 30min, until the powder was completely dissolved, added TEOS and continued to stir for 20min, then added triethylamine (TEA) to adjust the pH to 9-10, continued to stir for 2h, then transferred the solution to a hydrothermal kettle, at 200 Crystallization at ℃ for 48h;

[0049] Then the obtained crystallized product was cooled and filtered, washed three times with deionized water and ethanol, and dried at 100°C for 12 hours to obtain the original powder of molecular sieve loaded with palladium; then the original powder of mo...

Embodiment 3

[0051] This embodiment provides a catalyst for purifying dimethyldichlorosilane, the raw material of which comprises TEOS, Pd(NO 3 ) 2 2H 2 O, Zn(NO 3 ) 2 ·6H 2 O, AlCl 3 and H 2 O.

[0052] The preparation method of above-mentioned catalyst comprises the following steps,

[0053] At room temperature, the AlCl 3 , deionized water, Pd(NO 3 ) 2 2H 2 O and Zn(NO 3 ) 2 ·6H 2 O mixed according to the above ratio, stirred for 30min, until the powder was completely dissolved, added TEOS and continued to stir for 20min, then added triethylamine (TEA) to adjust the pH to 9-10, continued to stir for 2h, then transferred the solution to a hydrothermal kettle, at 200 Crystallization at ℃ for 48h;

[0054] Then the obtained crystallized product was cooled and filtered, washed three times with deionized water and ethanol, and dried at 100°C for 12 hours to obtain the original powder of molecular sieve loaded with palladium; then the original powder of molecular sieve was plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com