Acrylate microemulsion and preparation method thereof

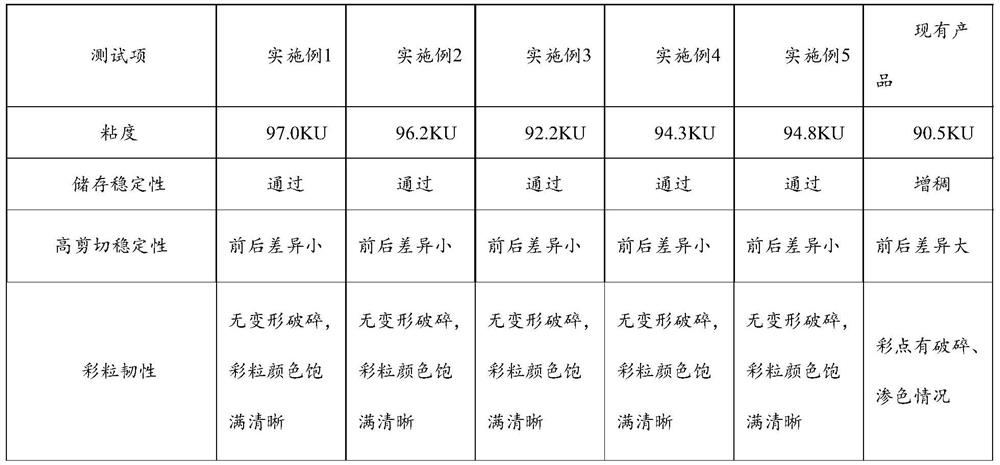

An acrylate and microemulsion technology, applied in the field of architectural colorful coatings, can solve problems such as poor high shear stability, difficulty in large-scale production, and long production cycle, and achieve excellent permeability and wettability, fast curing speed, and improved The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

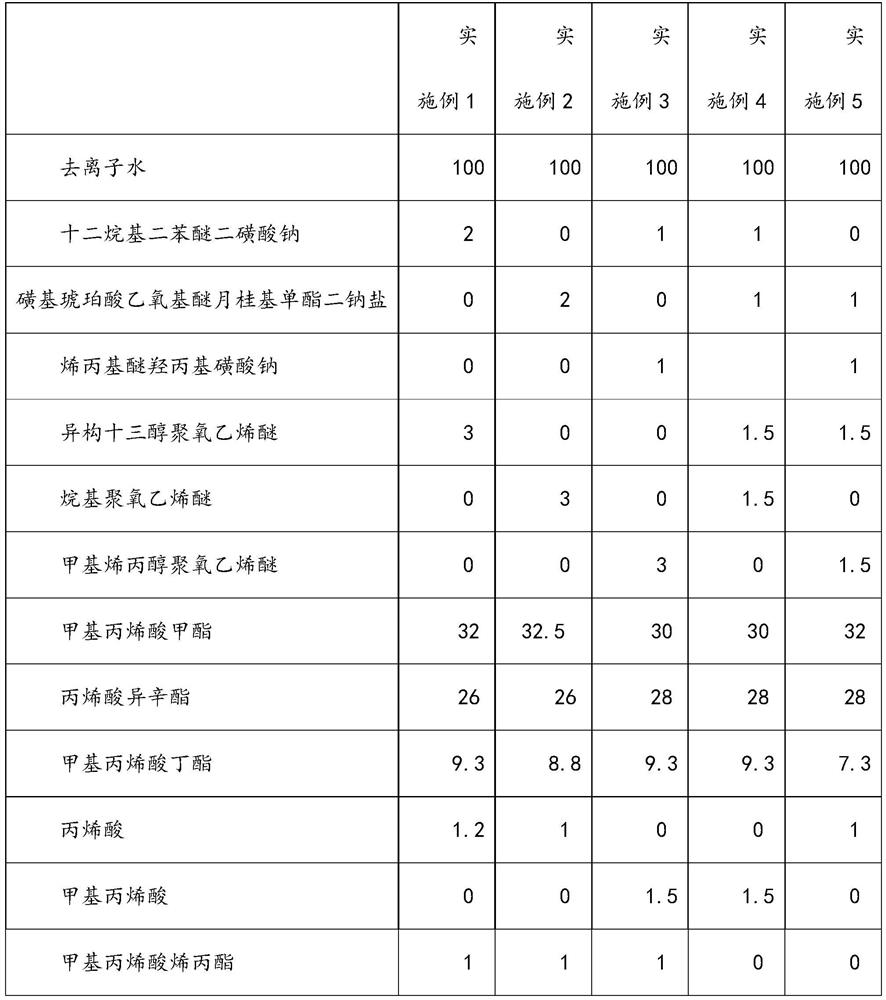

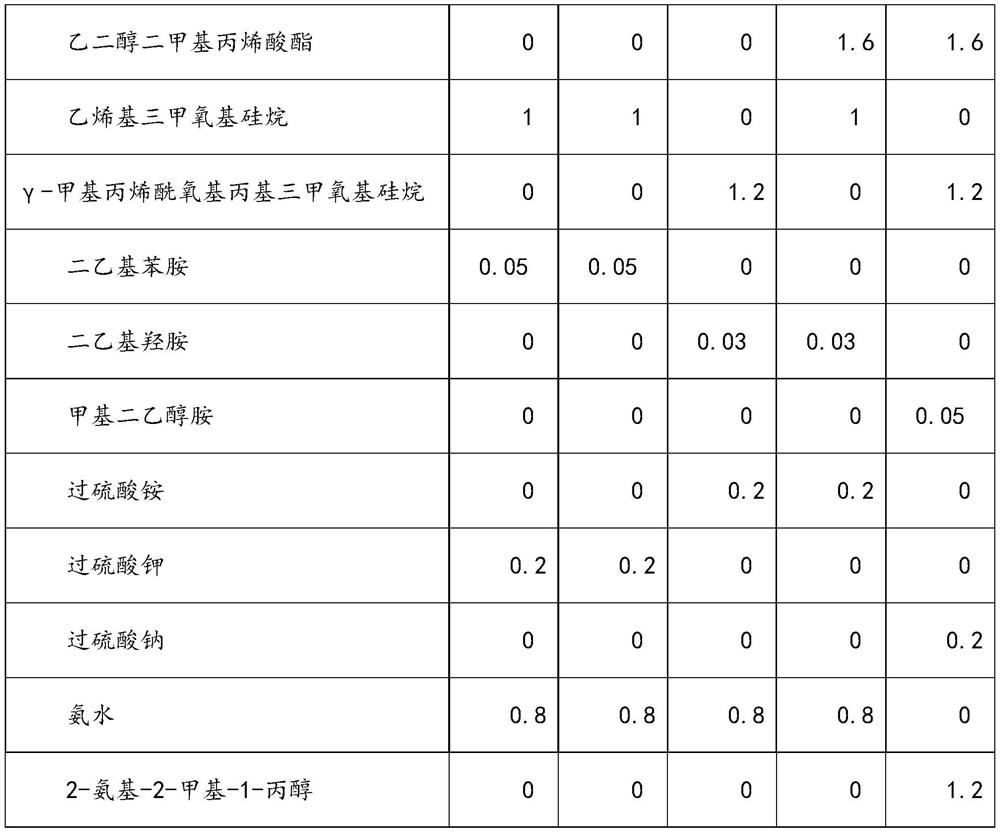

[0036] In some embodiments, the acrylate microemulsion includes deionized water, compound emulsifier, methyl methacrylate, isooctyl acrylate, butyl methacrylate, acid monomer, amine monomer, crosslinking Monomer, initiator, pH regulator, the above components can be calculated in parts by mass: 100 parts of deionized water, 2 parts of sodium dodecyl diphenyl ether disulfonate, isomeric tridecyl alcohol polyoxyethylene ether 3 parts, 32 parts of methyl methacrylate, 26 parts of isooctyl acrylate, 9.3 parts of butyl methacrylate, 1.2 parts of acrylic acid, 1 part of allyl methacrylate, 1 part of vinyltrimethoxysilane, diethyl 0.05 parts of aniline, 0.2 parts of potassium persulfate and 0.8 parts of ammonia water.

[0037] Specifically, the acrylate microemulsion can be prepared by the following method:

[0038] a. Preparation of initiator solution: Under normal temperature and pressure, take 20% of the total amount of initiator and 3% of the total amount of deionized water in th...

Embodiment 2

[0045] In some embodiments, the acrylate microemulsion includes deionized water, complex emulsifier, methyl methacrylate, isooctyl acrylate, butyl methacrylate, acid monomer, amine monomer, crosslinking monomer , initiator, pH regulator, the above components can be calculated in parts by mass: 100 parts of deionized water, 2 parts of sulfosuccinic acid ethoxy ether lauryl monoester disodium salt, 3 parts of alkyl polyoxyethylene ether 32.5 parts of methyl methacrylate, 26 parts of isooctyl acrylate, 8.8 parts of butyl methacrylate, 1 part of acrylic acid, 1 part of allyl methacrylate, 1 part of vinyltrimethoxysilane, diethyl 0.05 parts of aniline, 0.2 parts of potassium persulfate and 0.8 parts of ammonia water.

[0046] Specifically, the acrylate microemulsion can be prepared by the following method:

[0047]a. Preparation of initiator solution: Under normal temperature and pressure, take 20% of the total amount of initiator and 3% of the total amount of deionized water in t...

Embodiment 3

[0054] In some embodiments, the acrylate microemulsion includes deionized water, complex emulsifier, methyl methacrylate, isooctyl acrylate, butyl methacrylate, acid monomer, amine monomer, crosslinking monomer Body, initiator, pH regulator, the above components are calculated in parts by mass: 100 parts of deionized water, 1 part of sodium dodecyl diphenyl ether disulfonate, sodium allyl ether hydroxypropyl sulfonate 1 part, 3 parts of methallyl alcohol polyoxyethylene ether, 30 parts of methyl methacrylate, 28 parts of isooctyl acrylate, 9.3 parts of butyl methacrylate, 1.5 parts of methacrylic acid, allyl methacrylate 1 part, 1.2 parts of γ-methacryloxypropyltrimethoxysilane, 0.03 parts of diethylhydroxylamine, 0.2 parts of ammonium persulfate, and 0.8 parts of ammonia water.

[0055] Specifically, the acrylate microemulsion can be prepared by the following method:

[0056] a. Preparation of initiator solution: Under normal temperature and pressure, take 20% of the total a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com