PPR gray pipe color master batch and preparation method thereof

A pipe and color masterbatch technology, which is applied in the field of PPR gray pipe color masterbatch and its preparation, can solve problems such as the decline in mechanical properties of linear low-density polyethylene resin, improve environmental stress cracking resistance and mechanical properties, and strengthen bonding strength , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

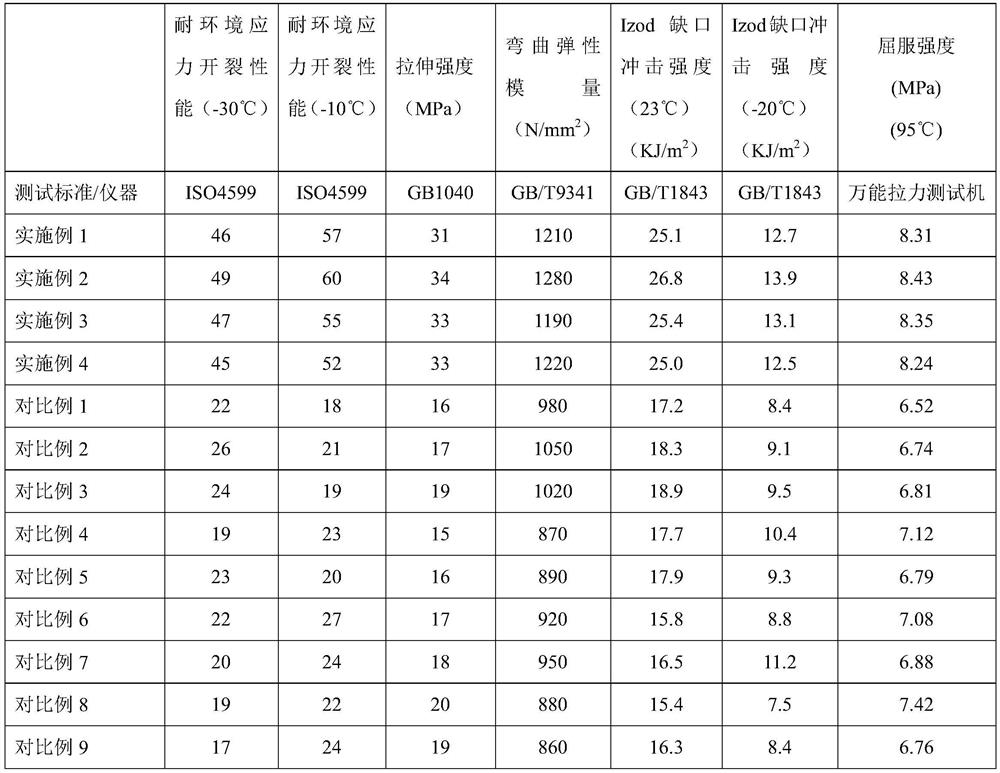

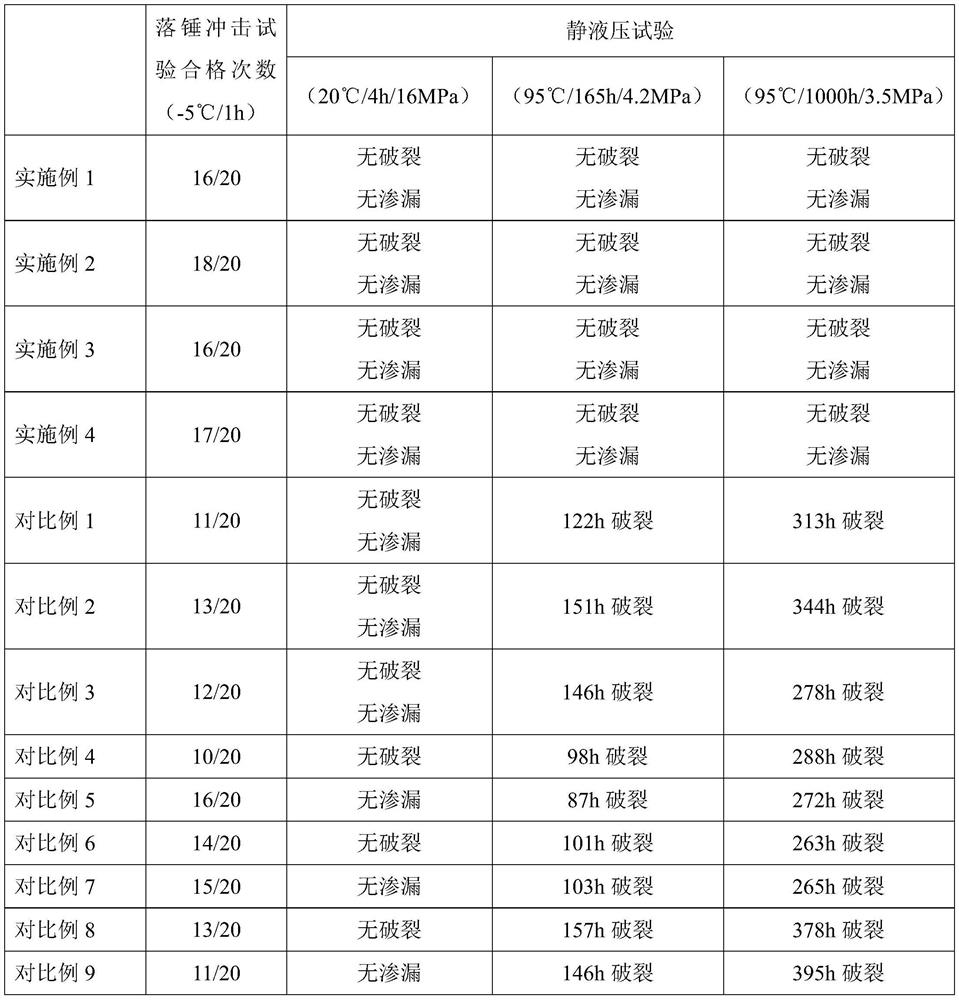

Examples

Embodiment 1

[0026] A PPR gray pipe color masterbatch, comprising the following blended components in parts by weight: 50 parts of linear low-density polyethylene, 1 part of PE wax, 1 part of zinc stearate, 10 parts of titanium dioxide, and 1 part of carbon black , 30 parts of alternating copolymers of dimethyl-(naphthalene-1-ylmethyl)-(2-octadecanoyloxyethyl)ammonium chloride and silane coupling agent KH-550, the average particle size of titanium dioxide is 20nm, the average particle size of carbon black is 20nm.

[0027] A preparation method of PPR gray pipe color masterbatch, comprising the following steps: (1) 10 parts of titanium dioxide, 1 part of carbon black, 1 part of zinc stearate, 30 parts of dimethyl-(naphthalene-1-ylmethyl )-(2-octadecanoyl oxyethyl) ammonium chloride and the alternating copolymer of silane coupling agent KH-550 are uniformly blended under high-speed stirring, the stirring time is 3 minutes, and the stirring rate of high-speed stirring is 3200 rpm / (2) Banbur...

Embodiment 2

[0029] A PPR gray pipe masterbatch, comprising the following blended components in parts by weight: 85 parts of linear low-density polyethylene, 5 parts of PE wax, 3 parts of zinc stearate, 25 parts of titanium dioxide, and 5 parts of carbon black , 40 parts of alternating copolymers of dimethyl-(naphthalene-1-ylmethyl)-(2-octadecanoyloxyethyl) ammonium chloride and silane coupling agent KH-550, the average particle size of titanium dioxide is 25nm, the average particle size of carbon black is 25nm.

[0030] A preparation method of PPR gray pipe color masterbatch, comprising the following steps: (1) 25 parts of titanium dioxide, 5 parts of carbon black, 3 parts of zinc stearate, 40 parts of dimethyl-(naphthalene-1-ylmethyl )-(2-octadecanoyloxyethyl) ammonium chloride and the alternating copolymer of silane coupling agent KH-550 are uniformly blended under high-speed stirring, the stirring time is 4 minutes, and the stirring rate of high-speed stirring is 3300 rpm / Minutes to ...

Embodiment 3

[0032]A PPR gray pipe masterbatch, comprising the following blended components in parts by weight: 100 parts of linear low-density polyethylene, 10 parts of PE wax, 5 parts of zinc stearate, 50 parts of titanium dioxide, and 10 parts of carbon black , 50 parts of alternating copolymers of dimethyl-(naphthalene-1-ylmethyl)-(2-octadecanoyloxyethyl)ammonium chloride and silane coupling agent KH-550, the average particle size of the titanium dioxide diameter is 30nm, and the average particle diameter of the carbon black is 30nm.

[0033] A preparation method of PPR gray pipe color masterbatch, comprising the following steps: (1) 50 parts of titanium dioxide, 10 parts of carbon black, 5 parts of zinc stearate, 50 parts of dimethyl-(naphthalene-1-ylmethyl )-(2-octadecanoyl oxyethyl) ammonium chloride and the alternating copolymer of silane coupling agent KH-550 are uniformly blended under high-speed stirring, the stirring time is 5 minutes, and the stirring rate of high-speed stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com