Force-induced color-changing material based on photonic crystal structure and preparation method thereof

A photonic crystal and color-changing technology, applied in the field of materials, can solve the problems of high product toxicity, complex synthesis process, application limitations, etc., and achieve the effect of simple steps and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

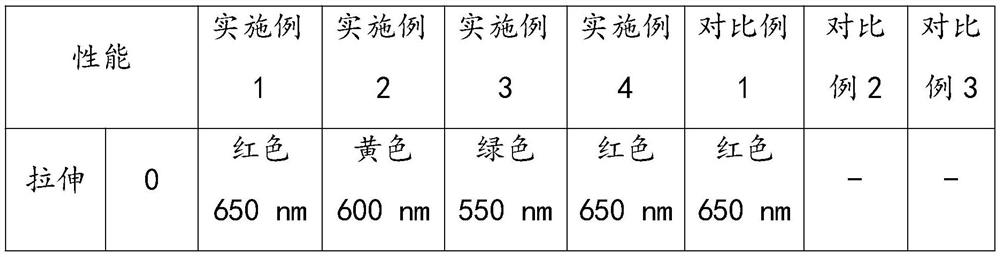

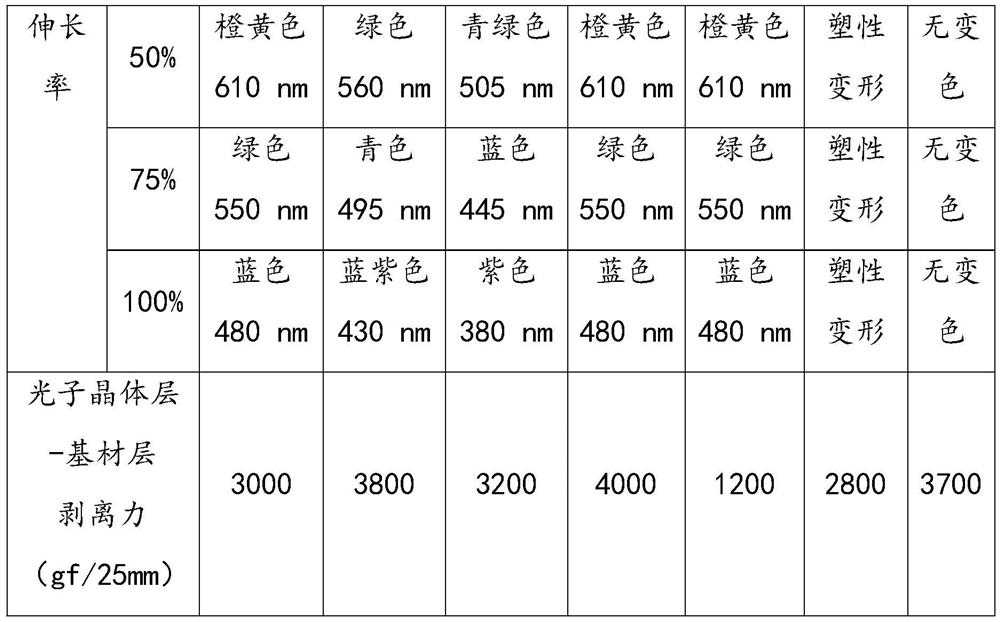

Embodiment 1

[0038] This embodiment provides a mechanochromic material based on photonic crystals, the preparation method of which is as follows:

[0039] Step 1: 100 parts by weight of nanospheres (the particle diameter of nanospheres is 250nm, and the polydispersity index PDI of nanospheres is 0.10), 50 parts by weight of butyl acrylate, 10 parts by weight of hydroxyethyl methacrylate and 5 parts by weight Mix parts by weight of urethane acrylate, and add appropriate amount of additives as required, such as UV stabilizer, light curing agent, film-forming agent, leveling agent and viscosity regulator, to adjust the viscosity of the slurry to 50-80cps.

[0040] Step 2: Apply the slurry evenly on the TPU substrate by slit coating, then dry the TPU composite film through a 25m oven at 80°C, and cover it with a PET protective film.

[0041] Step 3: The composite film is flattened by micro-stress rolling, and the speed is controlled at 30m / min. A photonic crystal layer is formed between the T...

Embodiment 2

[0043] The preparation method of the photonic crystal-based mechanochromic material of the present embodiment is basically the same as that of Example 1, the difference is that in step one, according to 100 parts by weight of nanospheres (the particle size of nanospheres is 230nm, the polydispersity of nanospheres Index PDI is 0.10), 40 parts by weight of butyl acrylate, 10 parts by weight of glycidyl methacrylate, 10 parts by weight of tripropylene glycol diacrylate, 10 parts by weight of hydroxyethyl methacrylate and 5 parts by weight of polyurethane acrylate mix.

Embodiment 3

[0045] The preparation method of the photonic crystal-based mechanochromic material of the present embodiment is basically the same as that of Example 1, the difference is that in step one, according to 100 parts by weight of nanospheres (the particle size of nanospheres is 200nm, the polydispersity of nanospheres index PDI is 0.10), 40 parts by weight of butyl acrylate, 20 parts by weight of isooctyl acrylate, 5 parts by weight of trifluoroethyl methacrylate, 15 parts by weight of hydroxypropyl acrylate and 2.5 parts by weight of polyurethane acrylate were mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com