Method for recovering valuable metals from waste lithium ion batteries

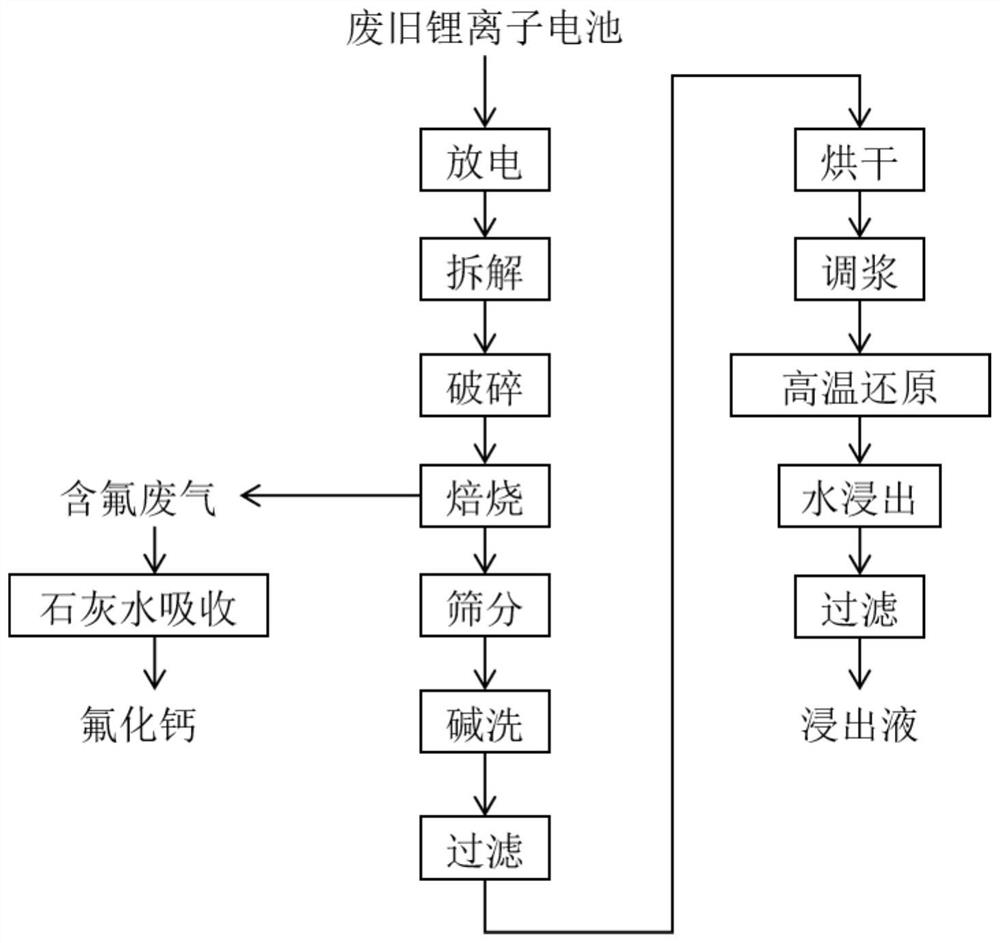

A lithium-ion battery and valuable metal technology, which is applied in battery recycling, waste collector recycling, secondary batteries, etc., can solve the problems of processing single waste lithium-ion batteries, secondary pollution of inorganic acid wastewater, and low product purity, etc. To avoid the loss of valuable metals, improve the comprehensive recovery rate, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Will be mixed with waste LiNiO 2 、LiCoO 2 , LiMnO 2 、LiNi x co y mn 1-x-y o 2 Lithium-ion batteries, that is, waste mixed lithium-ion batteries soaked in 5% sodium sulfite solution, discharged to a cut-off voltage of 1V; dismantling the discharged waste lithium-ion batteries to obtain battery components; mechanically integrating the battery components Crushed to obtain scraps, sieved the scraps with a particle size of less than 0.1mm and sent them to the roasting process; the scraps were heated to 400°C at a rate of 2°C / min in the air atmosphere, kept and roasted for 1h, and the adhesive was peeled off. The roasting exhaust gas is absorbed with 50mg / L lime water; the stripped products are separated to obtain Al, Cu foil and electrode active materials. Alkaline washing is carried out to the electrode active material powder produced by roasting, and the alkali washing parameters are as follows: NH of PH=10 4 OH solution, alkali washing time 10min, alkali washing te...

Embodiment 2

[0055] Soak the waste mixed lithium-ion battery in 10% sodium sulfite solution, and discharge it until the cut-off voltage is 0.8V; disassemble the discharged waste lithium-ion battery to obtain the battery components; mechanically crush the battery components as a whole to obtain broken pieces The crushed material with a particle size of less than 0.1mm is sieved and sent to the roasting process; the crushed material is heated up to 450°C at a rate of 5°C / min in the air atmosphere, kept for 1h, and the adhesive is peeled off, and the roasting waste gas is used 50mg / L lime water absorption; the stripped product is separated to obtain Al, Cu foil and electrode active material. Alkaline washing is carried out to the electrode active material powder produced by roasting, and the alkali washing parameters are as follows: NH of PH=10.5 4 OH solution, alkali washing time 20min, alkali washing temperature 25°C, filtration, separation and drying to obtain the electrode active material...

Embodiment 3

[0058] Soak the waste mixed lithium-ion battery in 15% sodium sulfite solution, and discharge it until the cut-off voltage is 0.7V; disassemble the discharged waste lithium-ion battery to obtain the battery components; mechanically crush the battery components to obtain broken pieces The crushed material with a particle size of less than 0.1mm is sieved and sent to the roasting process; the crushed material is heated up to 450°C at a rate of 10°C / min in the air atmosphere, kept for 1h, and the adhesive is peeled off, and the roasting waste gas is used 50mg / L lime water absorption; the stripped product is separated to obtain Al, Cu foil and electrode active material. Alkaline washing is carried out to the electrode active material powder produced by roasting, and the alkali washing parameters are as follows: NH of PH=12 4 OH solution, alkali washing time 30min, alkali washing temperature 35°C, filtration, separation and drying to obtain the electrode active material after alkal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com