Proton exchange membrane and preparation method thereof

A proton exchange membrane and microporous membrane technology, applied in the field of hydrogen fuel cells, can solve problems such as poor compatibility and easy loss of additives, and achieve the effects of improving water retention capacity, improving compatibility, and repairing internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment prepared perfluorosulfonic acid resin / SiO 2 - ePTFE microporous membrane proton exchange membrane, the specific method is as follows:

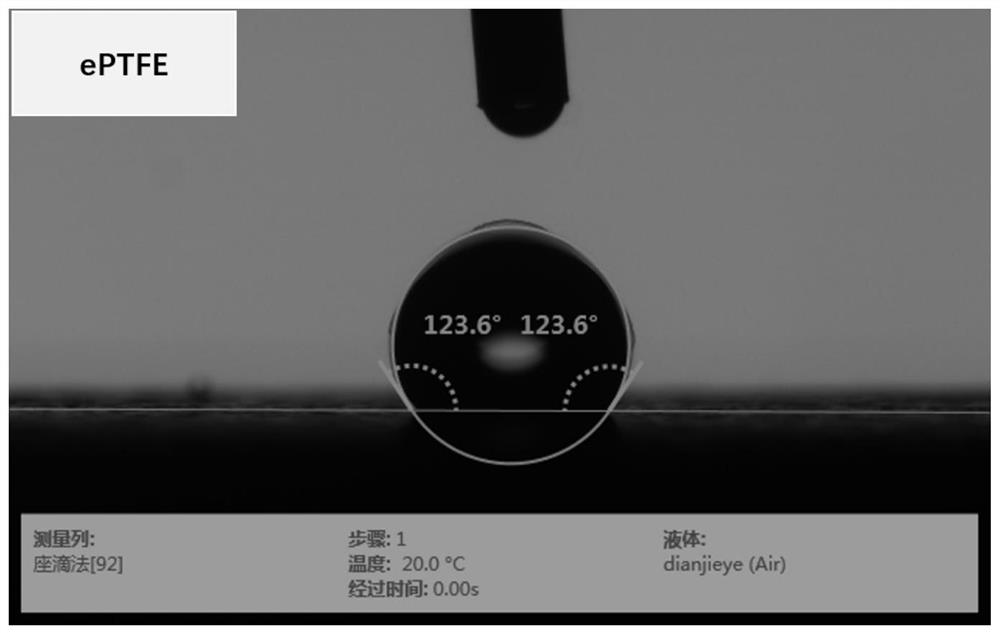

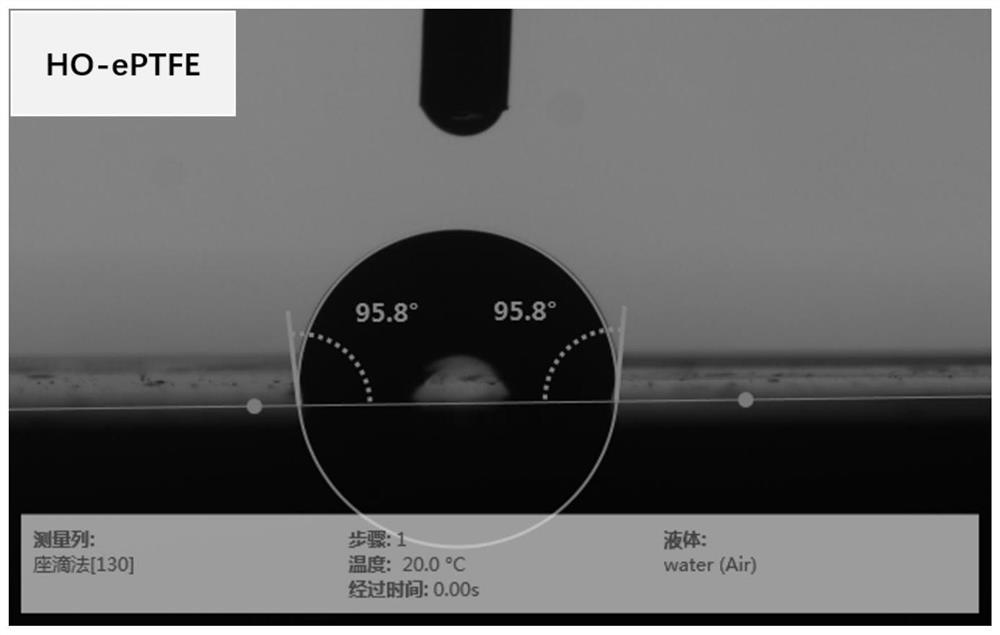

[0030] 1) Cut a 15*15cm ePTFE microporous membrane with a thickness of 15μm, a pore diameter of about 0.25μm, a porosity of 85%, a tensile strength of 35Mpa, and no wrinkles or damage on the surface. Place it in a special fixture and transfer it to the plasma equipment (OKSUN-RTR1000L-W600A). A vacuum pump is used to make the vacuum degree reach 10pa, and the radio frequency power is 100W; a mixed gas of argon and oxygen is used, and the gas flow rate is 50ml / min; the processing time is 300s. Finally, the primary treatment product is obtained, which is denoted as HO-ePTFE microporous membrane;

[0031] 2) Immediately transfer the treated HO-ePTFE microporous membrane to the atomic layer deposition instrument, choose SiCl 4 Alternate pulses with deionized water as a precursor into the reaction chamber for atomic layer ...

Embodiment 2

[0035] This embodiment prepared perfluorosulfonic acid resin / TiO 2 - ePTFE microporous membrane proton exchange membrane, the specific method is as follows:

[0036] 1) Cut a 15*15cm ePTFE microporous membrane with a thickness of 15μm, a pore diameter of about 0.25μm, a porosity of 85%, a tensile strength of 35Mpa, and no wrinkles or damage on the surface. Place it in a special fixture and transfer it to the plasma equipment middle. A vacuum pump is used to make the vacuum degree reach 10pa, and the radio frequency power is 100W; a mixed gas of argon and oxygen is used, and the gas flow rate is 50ml / min; the processing time is 300s. Finally, the primary treatment product is obtained, which is denoted as HO-ePTFE microporous membrane;

[0037] 2) Immediately transfer the treated HO-ePTFE microporous membrane to the atomic layer deposition instrument, choose TiCl 4 Alternate pulses with deionized water as a precursor into the reaction chamber for atomic layer deposition. Set...

Embodiment 3

[0041] This embodiment prepared perfluorosulfonic acid resin / SiO 2 / TiO 2 - ePTFE microporous membrane proton exchange membrane, the specific method is as follows:

[0042] 1) Cut a 15*15cm ePTFE microporous membrane with a thickness of 15μm, a pore diameter of about 0.25μm, a porosity of 85%, a tensile strength of 35Mpa, and no wrinkles or damage on the surface. Place it in a special fixture and transfer it to the plasma equipment middle. A vacuum pump is used to make the vacuum degree reach 10pa, and the radio frequency power is 100W; a mixed gas of argon and oxygen is used, and the gas flow rate is 50ml / min; the processing time is 300s. Finally, the primary treatment product is obtained, which is denoted as HO-ePTFE microporous membrane;

[0043] 2) Immediately transfer the treated HO-ePTFE microporous membrane to the atomic layer deposition instrument, choose SiCl 4 / TiCl 4 (mass ratio 1:1) and deionized water as precursors alternately pulsed into the reaction chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com