Method for producing sodium carbonate from carbon dioxide in flue gas and recovering ammonia gas by using magnesium oxide

A technology of carbon dioxide and magnesium oxide, which is applied in the direction of magnesium oxide, magnesium halide, magnesium chloride, etc., can solve the problems of high raw material prices and the inability to recycle ammonia gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

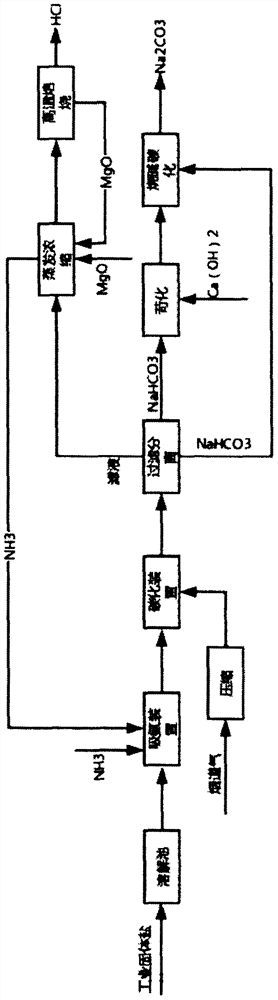

[0016] The ammonium chloride low-temperature evaporation device used for magnesia adsorption mother liquor is connected to the magnesia feed port through pipelines, and the ammonia gas outlet is connected to the ammonia absorption device through pipelines so that the ammonia gas can be recycled, and it comes from the magnesia after high-temperature roasting It is connected with a low-temperature evaporation device through a pipeline, and the outlet of the low-temperature evaporation device is connected with a high-temperature roasting through a pipeline.

[0017] The high-temperature roasting device used for high-temperature roasting basic magnesium chloride is connected to the low-temperature evaporation device through pipelines, and the magnesium oxide produced continues to return to the low-temperature roasting device for recycling, and the chlorine gas generated is collected through the outlet.

[0018] The causticizing device used for the causticizing reaction of heavy alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com