Preparation method of monodisperse large-size ultrathin two-dimensional strontium niobate nanosheet

A technology of strontium niobate and nanosheets, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of not meeting the large aspect ratio, non-uniformity, small size of SNO nano-powder, etc., and achieve low cost , the effect of high surface energy and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of above-mentioned nanometer material, comprises the following steps:

[0028] 1) Prepare a hydrothermal kettle with a capacity of 30-40% and a concentration of 3.8-4.2mol L -1 The potassium hydroxide solution, adding niobium pentoxide powder, the number of moles is 0.15-0.18 times of the moles of potassium hydroxide. Under the condition of 0-10°C cold water bath, pulse ultrasonic for 4-6h, the ultrasonic frequency is 20-25kHz, and the power is 150-200W. Heat treatment at 170-200°C for 12-24h;

[0029] 2) The clarified solution obtained in the first step is centrifuged to remove trace impurities at a high speed of 10000 r / min for 10 min. Use a syringe pump, slowly add strontium nitrate solution dropwise at 30-50ml / h, and continuously stir vigorously for 8-10h. Reaction 66-78h.

[0030] 3) Soak the obtained SNO powder in hydrochloric acid for 3-5 hours, then centrifuge and wash with absolute ethanol and deionized water for 3-5 times, and finall...

Embodiment 1

[0033] This embodiment is used to prepare soluble niobium salt solution, and the preparation method comprises the following steps:

[0034] 1) Prepare 35ml with a concentration of 4mol L -1 Potassium hydroxide solution was added to a 100ml polytetrafluoroethylene hydrothermal kettle lining.

[0035] 2) Add 0.5 g of niobium pentoxide powder into the potassium hydroxide solution above, and pulse ultrasonic for 5 hours under the condition of a cold water bath at 5° C., the ultrasonic frequency is 25 kHz, and the power is 200 W.

[0036] 3) Then heat-treat the above ultrasonically dispersed suspension at 180°C for 20 hours to obtain a clear soluble niobium salt solution. The soluble niobium salt is K 8 Nb 6 o 19 10H 2 O.

Embodiment 2

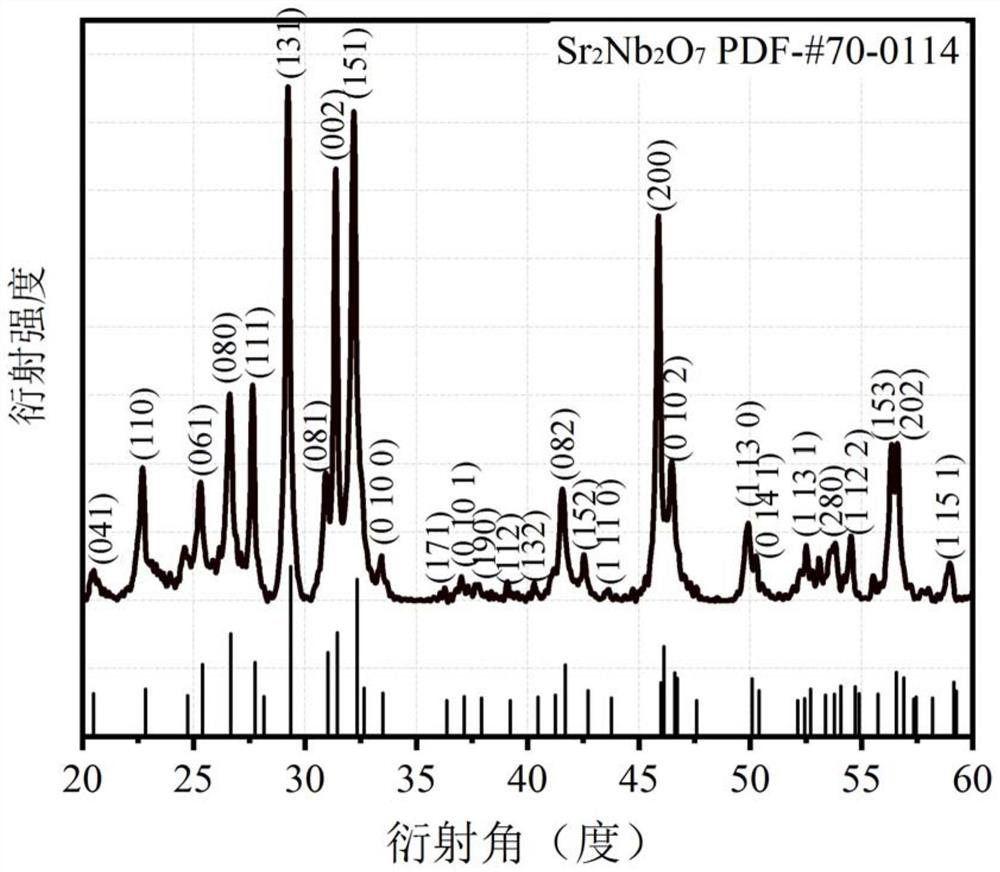

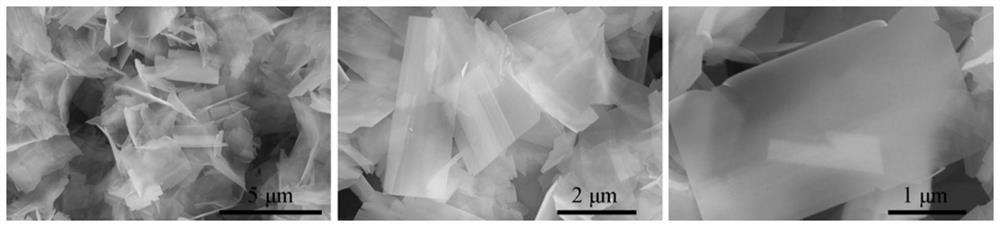

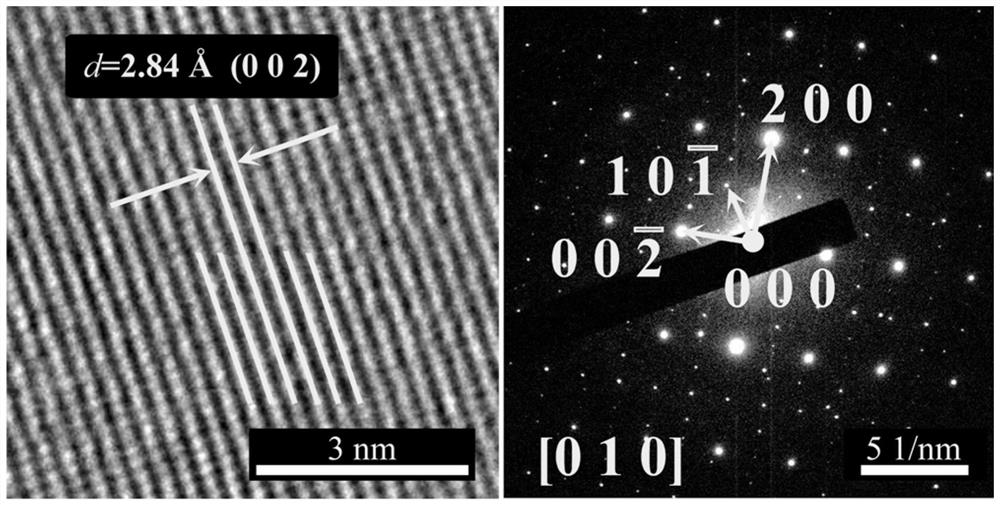

[0038] This embodiment is used for monodisperse large-size ultra-thin two-dimensional Sr 2 Nb 2 o 7 Preparation and characterization of (SNO) nanosheets, the preparation method includes:

[0039] 1) The clarified solution obtained in Example 1 was centrifuged at a high speed for 10min at a speed of 10000r / min, and transferred to a 100ml PPL-made hydrothermal kettle lining after removing trace impurities.

[0040] 2) Slowly add 35ml of 0.2mol / L strontium nitrate solution dropwise to the above solution, use a syringe pump during the dropping process, and the injection rate is 40ml / h, white milky matter will be formed during this process, so it needs to be continuously added during the dropping process Stir vigorously and keep stirring for 10 h, at this time the filling volume of the hydrothermal kettle is about 70%.

[0041]3) Seal the above white emulsion in a hydrothermal kettle, heat treatment for 72 hours, the heating process is 3°C / min from room temperature to 200°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com