Preparation method and application of high-refractive-index nano-zirconia composite resin

A technology of nano-zirconia and composite resin, which is applied in the field of optical films, can solve the problems of luminance loss, lower backlight efficiency, and easy deflection of light, and achieve the effect of reducing luminance loss and improving the degree of light concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

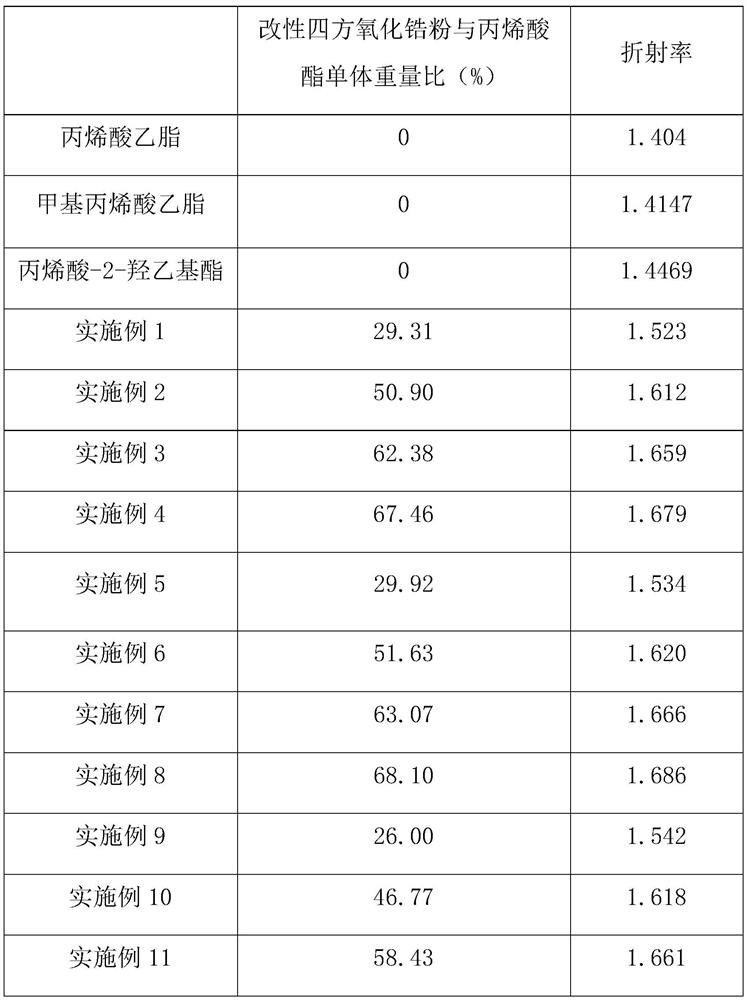

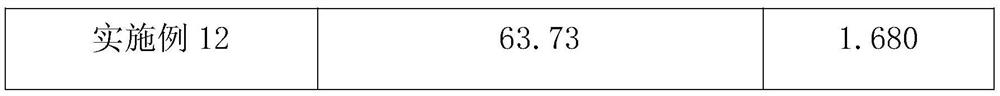

Examples

Embodiment 1

[0025] A kind of high refractive index nano zirconia composite resin, its preparation method comprises the following steps:

[0026] (1) Take ZrOCl 2 ·8H 2 O is dissolved in deionized water to obtain a 0.5mol / L zirconium oxychloride solution, adding NaOH to adjust the pH value to 10, adding glycerol, and the amount of glycerin added is ZrOCl 2 ·8H 2 0.5wt.% of the mass of O, stirred evenly, placed in a hydrothermal reaction kettle, reacted at 180°C for 24 hours, cooled to room temperature, took out the precipitate after centrifugation, and added H 3 PO 4 Adjust the pH value to 7, then add 25wt.% ethanol and leave it for 16 hours, centrifuge, wash with water, wash with ethanol, and spray powder to dry to obtain tetragonal zirconia powder with a particle size of 4nm;

[0027] (2) 75 parts by weight of tetragonal zirconia powder, 0.1 parts by weight of octadecyltrimethylammonium chloride and 800 parts by weight of deionized water are ultrasonically oscillated for 1 hour, and ...

Embodiment 2

[0030] The difference between Example 2 and Example 1 is that 14.06 g of modified tetragonal zirconia powder prepared in step (2) was dispersed into 30 mL of ethyl acrylate monomer to obtain a high refractive index nano-zirconia composite resin material.

Embodiment 3

[0032] The difference between Example 3 and Example 1 is that 17.24 g of modified tetragonal zirconia powder prepared in step (2) was dispersed into 30 mL of ethyl acrylate monomer to obtain a high refractive index nano-zirconia composite resin material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com