Method for simultaneously determining octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane and dodecamethylcyclohexasiloxane

A technology of dodecamethylcyclohexasiloxane and decamethylcyclopentasiloxane is applied in the field of component detection to achieve the effects of simple method, good reproducibility, high sensitivity and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

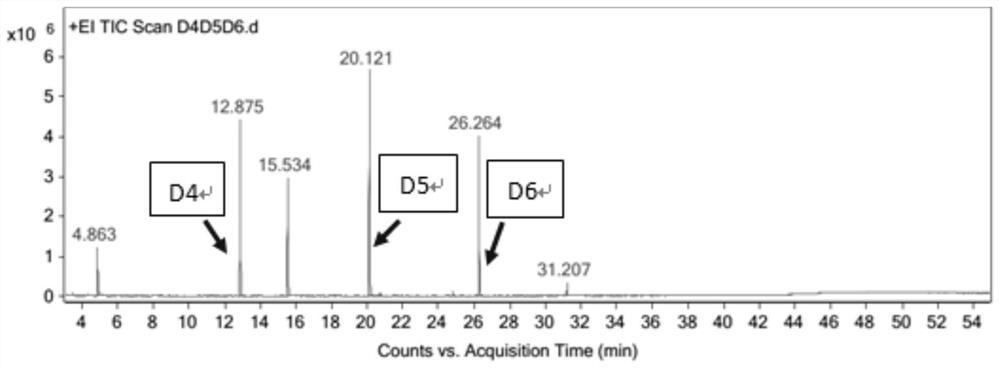

[0075] Determination of D4, D5, D6 correction factors

[0076] (1) Instruments, standard selection and preparation of standard solutions

[0077] The instrument used in this experiment is the Agilent 7890B gas chromatograph, equipped with the Agilent 5977B mass spectrometer detector, and the thermal desorption sampler is the Gerstel TDSA type. The analytical column was selected from Agilent mass spectrometry special capillary column, model is 5% phenylmethylsiloxane, 0.52μm×0.32mm×50m.

[0078]In this experiment, D4, D5, and D6 were selected as the standard products to be tested, and the purity was greater than 99.99%. If the purity was not enough, its content should be detected by gas chromatography before use. Accurately weigh 25mg (accurate to 0.1mg) of D4, D5, D6, add to a 50mL volumetric flask, then add methanol to below the scale line, cover and vibrate, then add methanol to the scale line and shake well, calculate D4 , D5, D6 concentration (μg / μl) of each component. ...

Embodiment 2

[0091] Determination experiment of components D4, D5 and D6 in different types of flexible polyurethane foam

[0092] (1) Foam sample preparation

[0093] Take 6 different grades of flexible polyurethane foam silicone oil, numbered 1# to 6#, at a temperature of 20-25°C, weigh each component except isocyanate in the experimental container according to the formula in Table 3, mix them evenly, and configure Form a composition, mix it with a certain amount of isocyanate, and immediately mix it with a high-speed mechanical agitator (3000-7000r / min) for 6 seconds, record the milky white and gel time, and cut the sample for testing after the foam is cured.

[0094] Table 3 Flexible polyurethane foam foaming formula:

[0095] components number of copies Isocyanate index 106 TDI 50 Polyether polyol 100 water 4 Soft polyurethane foam silicone oil 0.5 stannous octoate 0.2 Organic amine catalyst 0.5

[0096] 1# to 6# provided in ...

Embodiment 3

[0106] Parallel Determination Experiment of D4, D5, D6 Content in Flexible Polyurethane Foam

[0107] Test sample preparation: select a soft polyurethane foam sample, cut it into 10 pieces, each sample is 0.0100g-0.0200g, the data is accurate to four decimal places, and record the sample weight. The samples were cut into granules and stuffed into empty desorption tubes respectively, and the two ends of the samples were blocked with inactivated glass wool. At the same time, make a blank control sample.

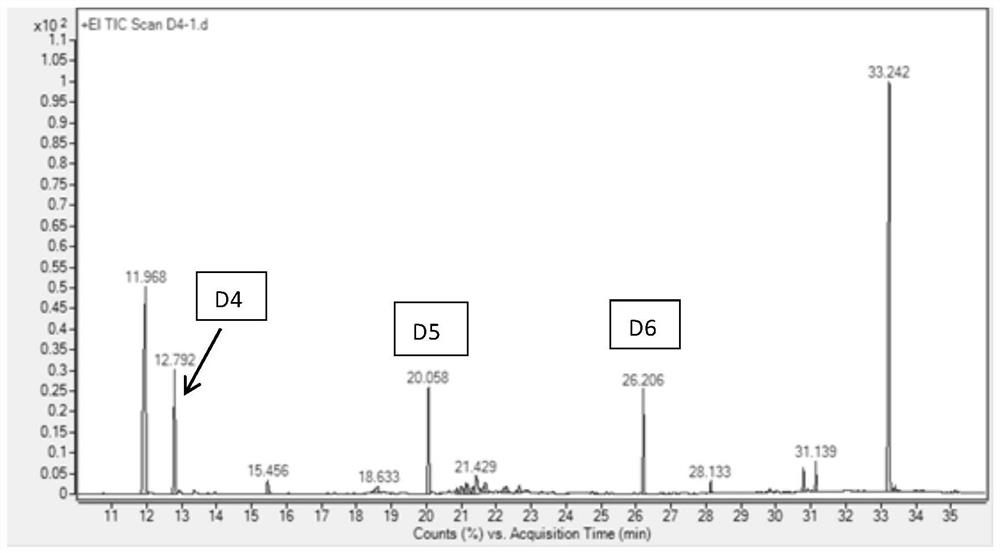

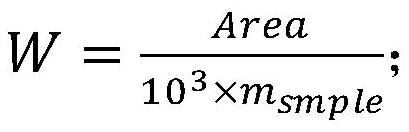

[0108] Detection and data processing: put the desorption tube of the filled sample and the desorption tube of the blank control sample into the sampling tray of the thermal desorption-mass spectrometry instrument, after setting the instrument according to the instrument parameters in Example 1, start to carry out sample detection. After the experiment was completed, the analysis software was used to read the total ion chromatogram, and the D4, D5, and D6 components in the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com