Copper surface passivation composition, application thereof, and photoresist stripping liquid containing copper surface passivation composition

A technology of copper surface and composition, applied in the application field of microelectronics technology, can solve problems such as poor electrical performance of finished products, roughened metal wiring, and decreased product yield, achieving no residual pollutants, good environmental protection, and reduced pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

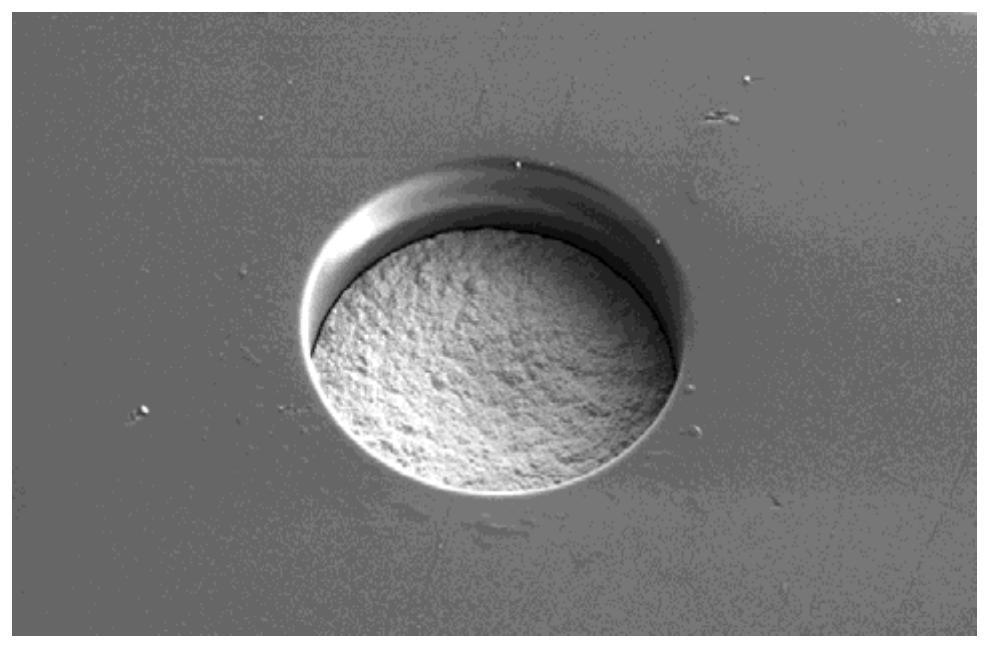

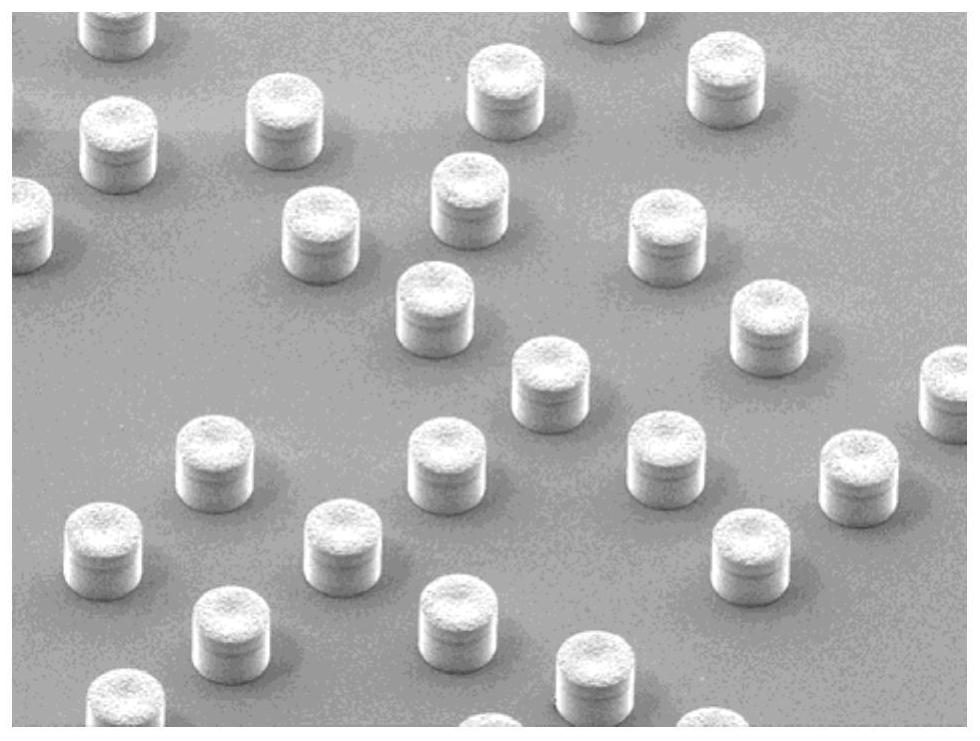

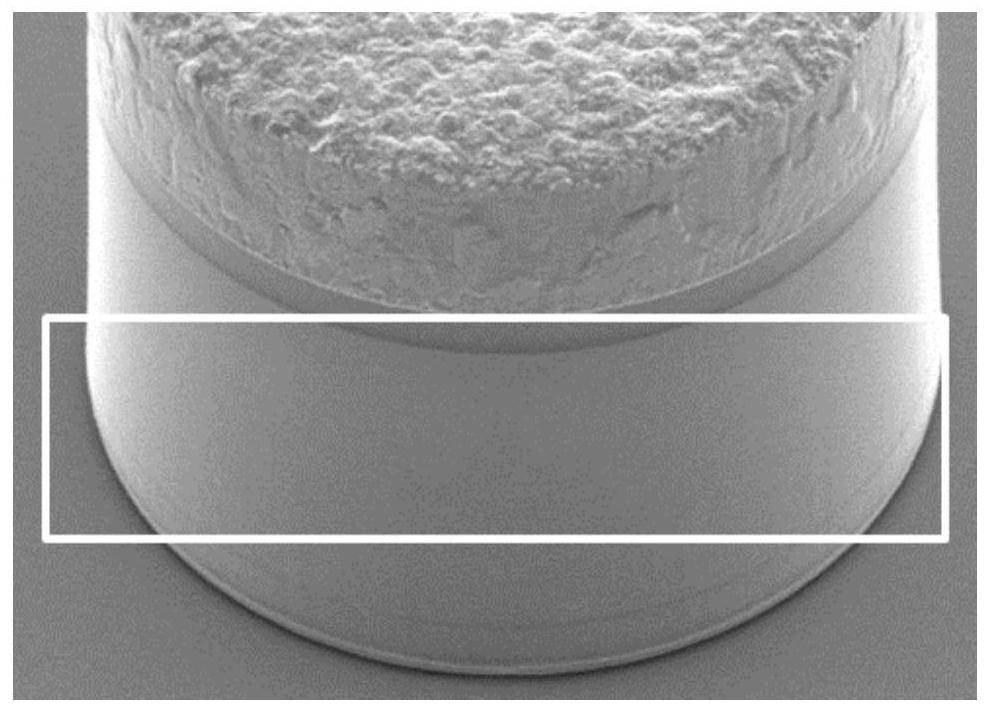

Image

Examples

Embodiment 1

[0080] Embodiment 1: Preparation of photoresist stripping solution

[0081] Step 1: Weigh the following components by mass respectively: 0.5 parts of copper surface passivation composition (4-(2-pyridylazo) resorcinol and N-acetyl-D - a mixture of glucosamine), 75 parts of water-soluble organic solvent diethylene glycol monoethyl ether, 21 parts of base N-ethylethanolamine, 17.5 parts of polyol 1,3-propylene glycol and 5.5 parts of deionized water;

[0082] Step 2: Add the copper surface passivation composition, water-soluble organic solvent, alkali and polyhydric alcohol into deionized water at room temperature, and fully stir and mix evenly to obtain a uniform and transparent photoresist stripping solution. Name it G1.

Embodiment 2

[0083] Embodiment 2: Preparation of photoresist stripping solution

[0084] Step 1: Weigh the following components by mass respectively: 1 part of copper surface passivation composition (4-(2-pyridylazo) resorcinol and N-acetyl-D - a mixture of glucosamine), 60 parts of water-soluble organic solvent dimethylsulfoxide, 40 parts of base benzyltrimethylammonium hydroxide, 5 parts of polyol diethylene glycol and 10 parts of deionized water;

[0085] Step 2: Add water-soluble organic solvent, alkali and polyol to deionized water at room temperature to obtain a mixed solution, then add the copper surface passivation composition to the mixed solution under stirring, and fully stir and mix evenly , to obtain a uniform and transparent photoresist stripping solution, which is named G2.

Embodiment 3

[0086] Embodiment 3: Preparation of photoresist stripping solution

[0087] Step 1: Weigh the following components by mass respectively: 0.01 part of copper surface passivation composition (4-(2-pyridylazo) resorcinol and N-acetyl-D - a mixture of glucosamine), 90 parts of water-soluble organic solvent sulfolane, 2 parts of alkali tetramethylammonium hydroxide, 30 parts of polyol ethylene glycol and 1 part of deionized water;

[0088] Step 2: Add the copper surface passivation composition, water-soluble organic solvent, alkali and polyhydric alcohol into deionized water at room temperature, and fully stir and mix evenly to obtain a uniform and transparent photoresist stripping solution. Named G3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com