Preparation method of sludge extracellular polymeric substance composite nano zero-valent iron

A technology of extracellular polymers and nano-zero-valent iron, which is applied in the direction of water pollutants, nanotechnology, chemical instruments and methods, etc., can solve the problems of the preparation cost of secondary polluting microbial extracellular secretions, achieve high reduction and adsorption efficiency, Improved removal effect, easy zoom-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of sludge extracellular polymer composite nano-zero-valent iron in this embodiment is carried out according to the following steps:

[0020] 1. Preparation of sludge extracellular polymer

[0021] The activated sludge is left to settle, the supernatant is removed, and the remaining material is heated to 75-85°C in a water bath, and then anhydrous NaCO is added 3 , to obtain a mixture, stir the mixture, then centrifuge to collect the supernatant and discard the precipitate, the obtained supernatant is the extracted sludge extracellular polymer;

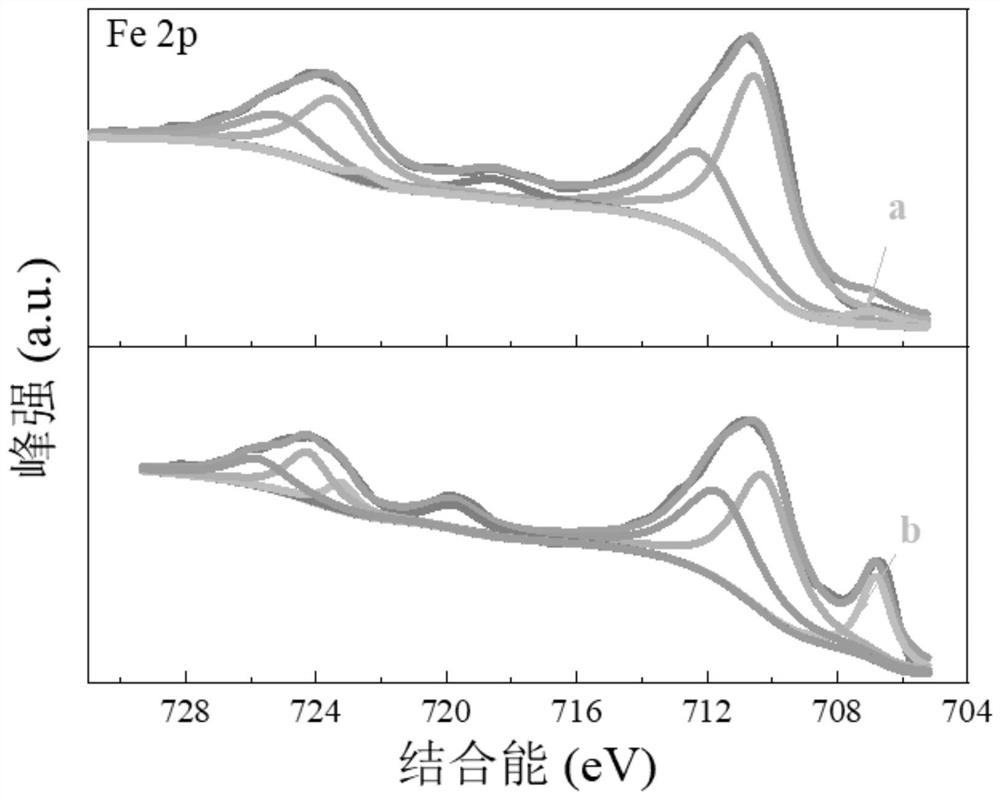

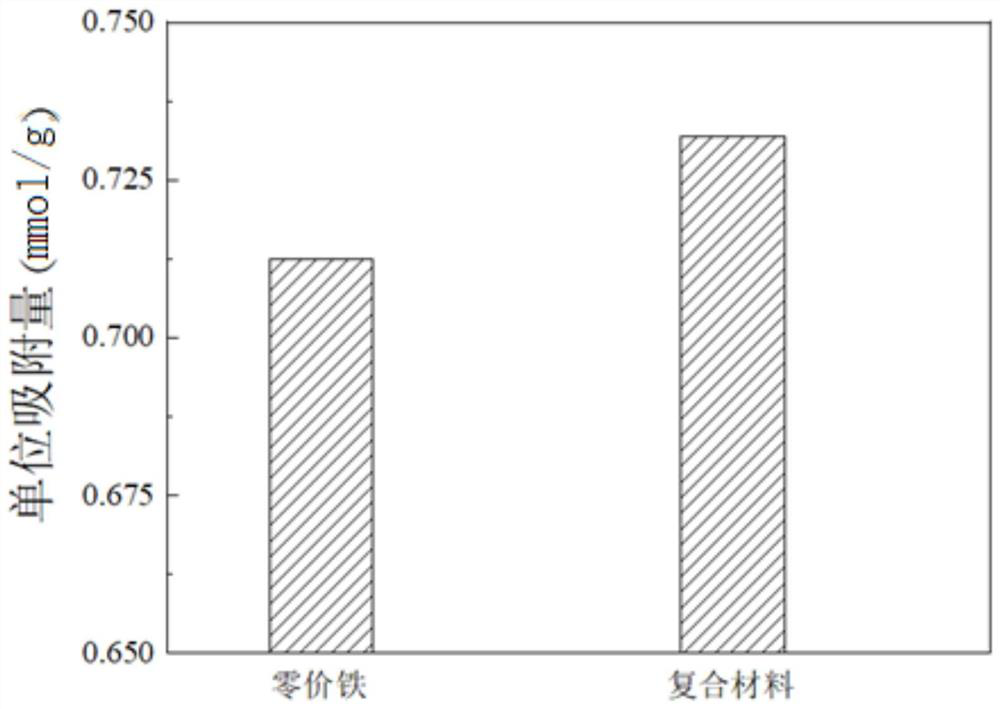

[0022] 2. Preparation of sludge extracellular polymer composite nano-zero valent iron

[0023] Take sludge extracellular polymer, aerate with nitrogen for 25-35 minutes, then add FeCl 3 ·6H 2 O, adjust the pH value of sludge extracellular polymer to FeCl with HCl 3 ·6H 2 O dissolved, then NaBH was added 4 The aqueous solution is stirred for 25 to 35 minutes under the protecti...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the volume of activated sludge described in step one and anhydrous NaCO 3 The mass ratio is (199~201)mL:0.33g.

specific Embodiment approach 3

[0028] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: when stirring the mixture in step 1, stir at a speed of 395-405 r / min for 35 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com