Nano nickel ferrite/zinc titanate modified microporous silicon oxide as well as preparation method and application thereof

A technology of nano-nickel ferrite and zinc titanate, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Change, difficult to recycle and other problems, to achieve the effect of improving light conversion efficiency and catalytic performance, improving photocatalytic activity, improving photocatalytic efficiency and catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

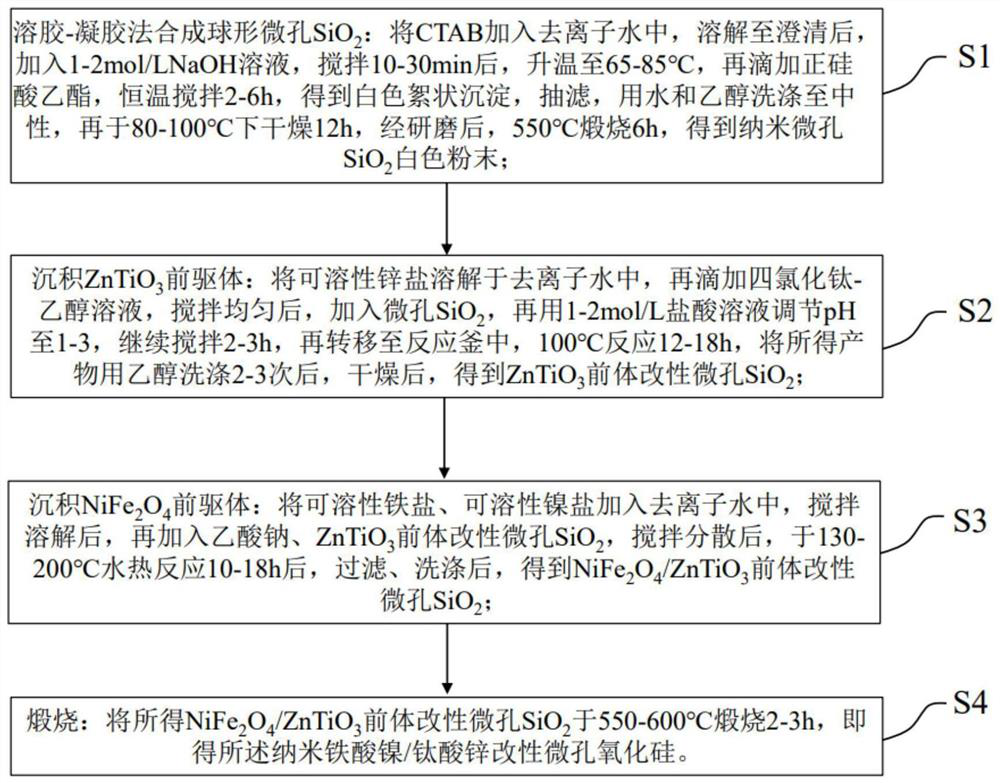

[0028] The preparation method of the nano-nickel ferrite / zinc titanate modified microporous silicon oxide of this embodiment comprises the following steps:

[0029] S1: Synthesis of spherical microporous SiO by sol-gel method 2 : Add CTAB into deionized water, dissolve until clear, add 1-2mol / L NaOH solution, stir for 10-30min, heat up to 65-85°C, then add ethyl orthosilicate dropwise, and stir at constant temperature for 2-6h to obtain White flocculent precipitate, suction filtered, washed with water and ethanol until neutral, then dried at 80-100°C for 12 hours, after grinding, calcined at 550°C for 6 hours to obtain nanoporous SiO 2 White powder; the dosage ratio of the CTAB, deionized water, NaOH solution, and ethyl orthosilicate is (0.2-0.4) g: (1.5-2) mL: (3.0-4.5) mL: 5 mL;

[0030] S2: Deposition of ZnTiO 3Precursor: Dissolve soluble zinc salt in deionized water, then add titanium tetrachloride-ethanol solution dropwise, stir well, then add microporous SiO 2 , then ...

Embodiment 1

[0035] A method for preparing nano-nickel ferrite / zinc titanate modified microporous silicon oxide of an embodiment, comprising the following steps:

[0036] S1: Synthesis of spherical microporous SiO by sol-gel method 2 : Add 0.4g CTAB into 3mL deionized water, dissolve until clear, add 6mL of 1mol / L NaOH solution, stir for 10min, heat up to 65°C, then add 10mL tetraethyl orthosilicate dropwise, and stir at constant temperature for 2h to obtain white flocs Precipitate, filtered, washed with water and ethanol until neutral, then dried at 80°C for 12h, ground, calcined at 550°C for 6h to obtain nanoporous SiO 2 White powder;

[0037] S2: Deposition of ZnTiO 3 Precursor: Dissolve 0.0025mol zinc chloride in 50mL deionized water, then add dropwise 5mL of 0.5mol / L titanium tetrachloride-ethanol solution, stir well, then add 3g microporous SiO 2 , then adjust the pH to 2 with 1mol / L hydrochloric acid solution, continue to stir for 2h, then transfer to the reaction kettle, react a...

Embodiment 2

[0041] A method for preparing nano-nickel ferrite / zinc titanate modified microporous silicon oxide of an embodiment, comprising the following steps: S1: Synthesizing spherical microporous SiO by sol-gel method 2 : Add 0.6g CTAB into 3.5mL deionized water, dissolve until clear, add 7.5mL of 1.5mol / L NaOH solution, stir for 20min, then raise the temperature to 75°C, then add dropwise 10mL of ethyl orthosilicate, and stir at constant temperature for 4h, The white flocculent precipitate was obtained, filtered by suction, washed with water and ethanol until neutral, then dried at 100°C for 12h, after grinding, calcined at 550°C for 6h to obtain nanoporous SiO 2 White powder;

[0042] S2: Deposition of ZnTiO 3 Precursor: Dissolve 0.00375mol zinc nitrate in 50mL deionized water, then add dropwise 5mL of 0.75mol / L titanium tetrachloride-ethanol solution, stir well, then add 3g microporous SiO 2 , and then adjust the pH to 2 with 1.5mol / L hydrochloric acid solution, continue to stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com