Conjugated microporous polymer as well as preparation method and application thereof

A technology of conjugated micropores and polymers, applied in the field of chemical analysis, to achieve low detection limit, high specific surface area and chemical stability, and meet the detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Synthesis of OH-CMP:

[0051] In a 100mL three-necked flask, sequentially add 1,3,5-tris(4-ethynylphenyl)benzene (0.4mmol, 152mg), tribromophenol (0.4mmol, 132mg), 4.0mL N,N-dimethylmethane amide and 12.0 mL of triethylamine. After three vacuum-N 2 After recycling, tetrakis(triphenylphosphine)palladium catalyst (0.07mmol, 80mg), CuI (0.21mmol, 40mg), 8.0mL N,N-dimethylformamide were added thereto. Then, three more vacuum-N 2 Circulation, the temperature of the oil bath was raised to 40°C, and after keeping for 1 hour, the temperature was adjusted to 100°C, and the reaction was carried out for 72 hours, and a dark brown solid precipitate was obtained at the bottom. After the precipitate was suction-filtered, it was washed three times with water, methanol, and acetonitrile to remove excess impurities; finally, the obtained solid was dried in an oven at 60°C for 24 hours to obtain a dark brown powder.

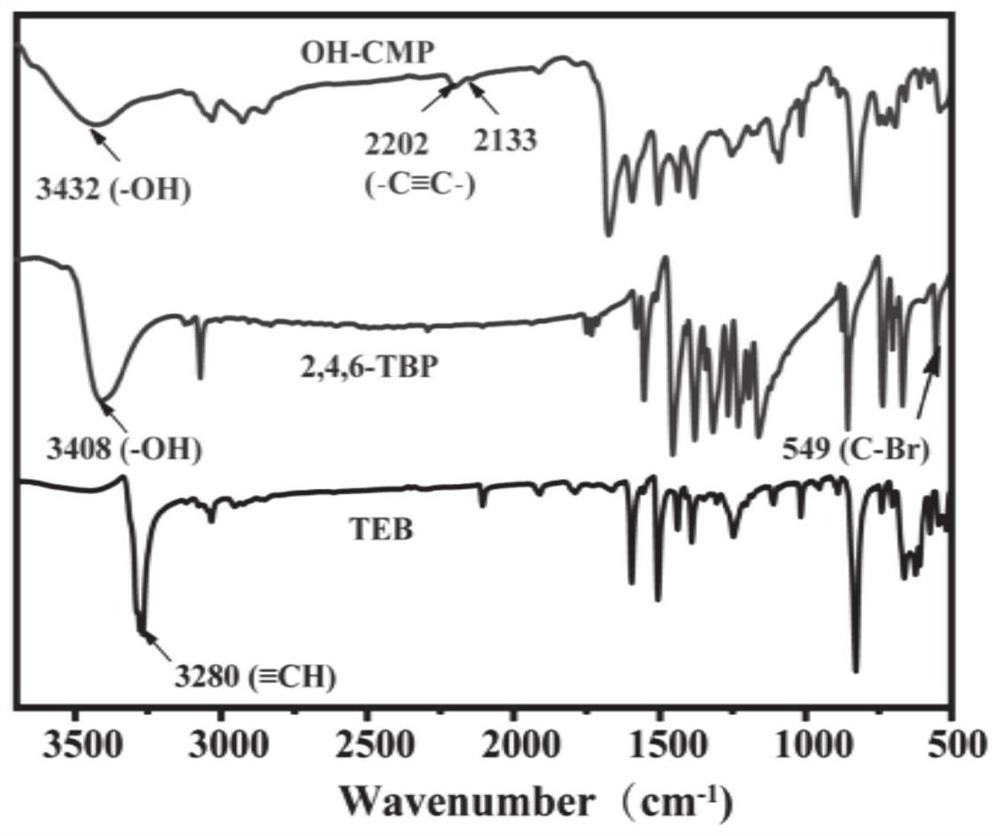

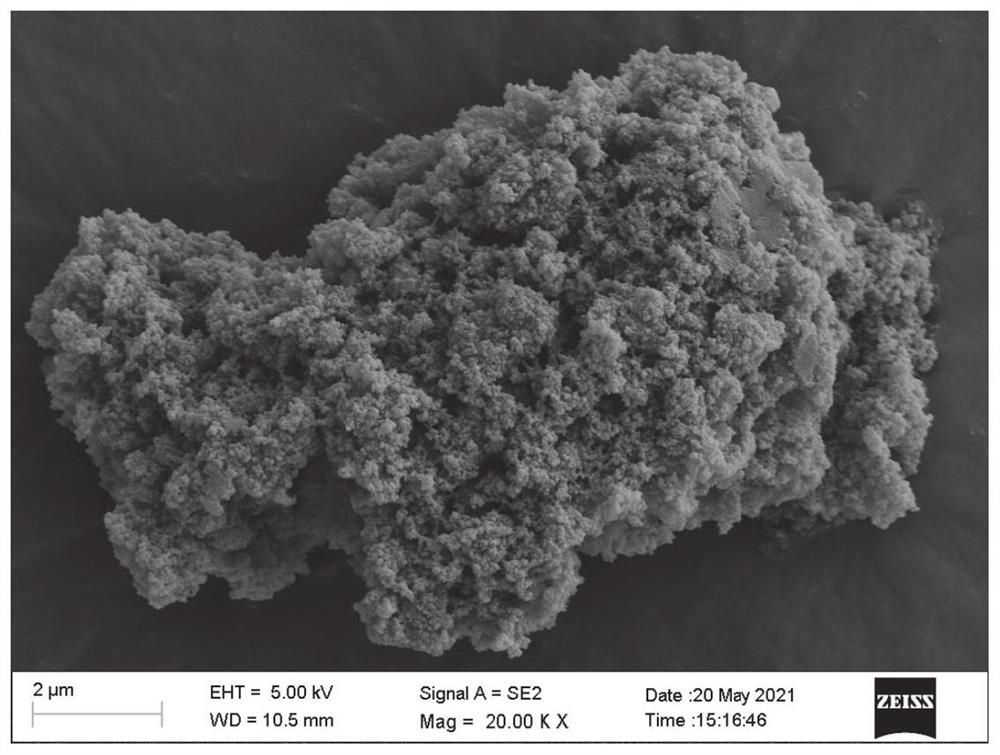

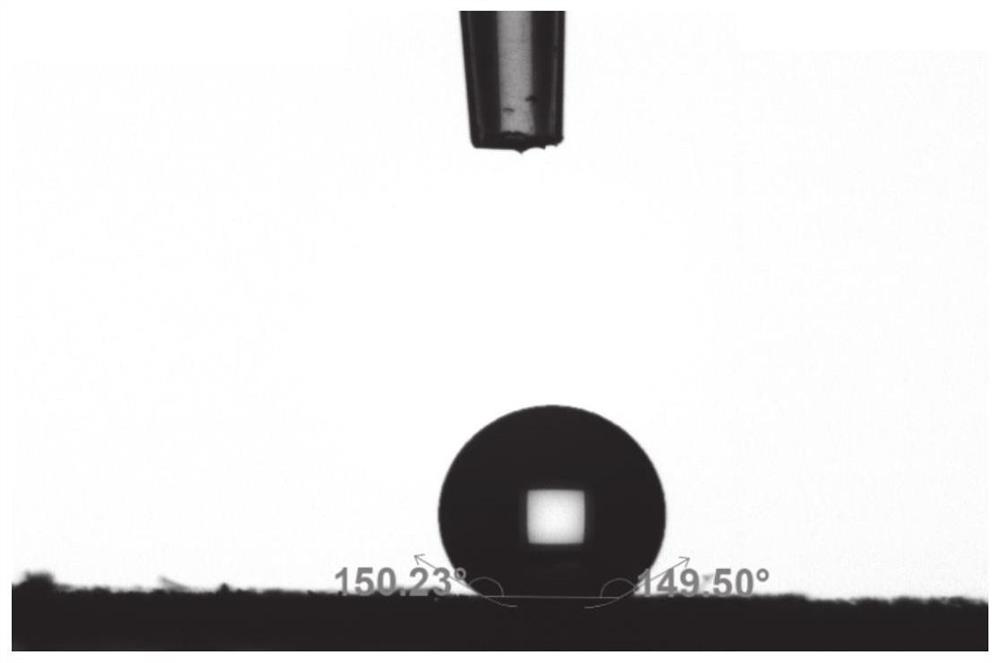

[0052] Characterization analysis of OH-CMP:

[0053] Such as fig...

Embodiment 2

[0055] Synthesis of OH-CMP:

[0056] In a 100mL three-necked flask, sequentially add 1,3,5-tris(4-ethynylphenyl)benzene (0.4mmol, 152mg), tribromophenol (0.4mmol, 132mg), 4.0mL N,N-dimethylmethane amide and 12.0 mL of triethylamine. After three vacuum-N 2 After recycling, tetrakis(triphenylphosphine)palladium catalyst (0.07mmol, 80mg), CuI (0.21mmol, 40mg), 8.0mL N,N-dimethylformamide were added thereto. Then, three more vacuum-N 2 Circulation, the temperature of the oil bath rose to 42°C, and after keeping for 1.2h, the temperature was adjusted to 105°C, and the reaction was carried out for 75h, and a dark brown solid precipitate was obtained at the bottom. After the precipitate was suction-filtered, it was washed three times with water, methanol, and acetonitrile to remove excess impurities; finally, the obtained solid was dried in an oven at 65°C for 24 hours to obtain a dark brown powder.

Embodiment 3

[0058] Solid phase extraction process:

[0059] The manufacturing steps of the solid-phase extraction column are as follows: accurately weigh the adsorbent OH-CMP (30mg) synthesized in Example 1, fill it into the solid-phase extraction column that has been loaded into the sieve plate, and then cover with a layer of sieve plate, and press lightly. Finally, before extracting the target substance in the sample, wash the solid-phase extraction column with 50mL of acetonitrile and 50mL of pure water to remove excess impurities in the solid-phase extraction column.

[0060] Solid-phase extraction process: The solid-phase extraction method for triazine herbicides is as follows: first, activate the self-made solid-phase extraction column with 6mL acetonitrile and 6mL pure water with pH=4 respectively, and the activation flow rate is 0.5mL / min; Measure 100mL of water sample, connect one end of the polytetrafluoroethylene suction pipe to the inlet end of the solid phase extraction colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com