Aerogel surface high-temperature-resistant composite coating and preparation method thereof

A composite coating and aerogel technology, used in coatings, glass manufacturing equipment, fire-resistant coatings, etc., can solve the problems of poor anti-oxidation and anti-scour performance, large differences in components, and powder falling off. Improve anti-oxidation performance and anti-scour performance, easy operation, and the effect of isolating the entry of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

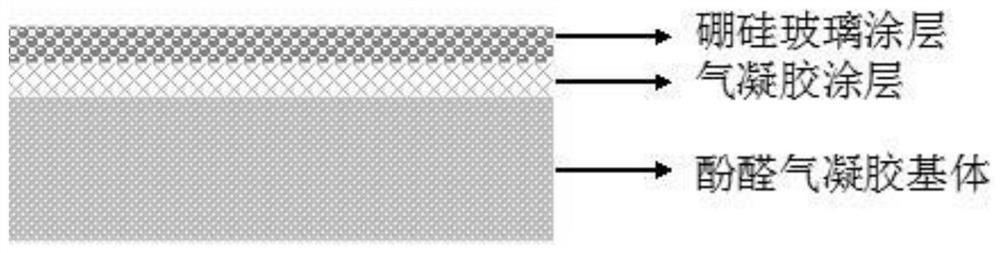

[0032] The invention provides a method for preparing a high temperature resistant composite coating on the surface of an airgel, the preparation method comprising the following steps:

[0033] (1) Airgel and inorganic oxide sol are mixed to obtain airgel coating;

[0034] (2) will B 2 o 3 Powder, Al 2 o 3 Powder and SiO 2 Powders are mixed and sintered, and then a solvent is added for ball milling to obtain a borosilicate glass coating;

[0035] (3) The airgel coating is applied to the substrate surface, and the airgel coating is obtained after drying;

[0036] (4) Applying the borosilicate glass coating to the surface of the airgel coating, and drying to obtain a high temperature resistant composite coating on the airgel surface comprising a borosilicate glass coating.

[0037] In the prior art, a single airgel coating is loose and porous, and oxygen can easily pass through the coating to react with the substrate, causing the substrate to oxidize under high temperature ...

Embodiment 1

[0063] (1) The dried phenolic aerogel is added to Al with a solid content of 20%. 2 o 3 Carry out ball milling and mixing 2h in the sol, obtain airgel coating; Wherein, the addition amount of phenolic airgel is Al 2 o 3 20% of the sol;

[0064] (2) In terms of parts by mass, 5 parts of B 2 o 3 powder, 40 parts of Al 2 o 3 powder and 55 parts of SiO 2 The powders (both particle sizes are 200 μm) were ball milled and mixed for 4 hours, then sintered in an air atmosphere furnace at 1350°C for 3 hours, cooled naturally to room temperature (25°C), and then added a solvent with a volume ratio of ethanol:ethylene glycol=2:1 Perform ball milling and mixing for 6 hours to obtain borosilicate glass coating;

[0065] (3) The obtained airgel paint is applied to the surface of the phenolic airgel substrate by spraying (the thickness of the coating is 1mm), and after drying at 100°C for 3h, the airgel coating (thickness is 1mm);

[0066] (4) Apply the obtained borosilicate glass co...

Embodiment 2

[0068] (1) The dried carbon fiber composite phenolic airgel (wherein, the mass fraction of carbon fiber is 70%, the mass fraction of phenolic airgel is 30%, and the parameters of the used carbon fiber are completely consistent with the carbon fiber in the matrix) is added up to 30% solids SiO 2 Carry out ball milling and mixing in the sol for 6h to obtain the airgel coating; wherein the addition amount of the carbon fiber composite phenolic airgel is SiO 2 30% of the sol;

[0069] (2) In terms of parts by mass, 10 parts of B 2 o 3 powder, 50 parts of Al 2 o 3 powder and 40 parts of SiO 2 Powder (all particle sizes are 100 μm) was ball milled and mixed for 4 hours, then sintered in an air atmosphere furnace at 1500°C for 4 hours, cooled naturally to room temperature (25°C), and then added with ethanol solvent for ball milling and mixed for 7 hours to obtain borosilicate glass coating;

[0070] (3) the obtained airgel coating is applied to the surface of the carbon fiber c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com