Device for preparing cell cluster, and construction method and application of device

A cell and cluster technology, used in tissue cell/virus culture devices, biochemical equipment and methods, biochemical instruments, etc., can solve the problem that the size and shape of the micropores cannot meet the custom requirements, and it is difficult to obtain a large number of cell clusters. , quantity, size and other problems, to achieve the effect of controllable physical and chemical properties, avoiding the reversal of yin and yang molds, and controllable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

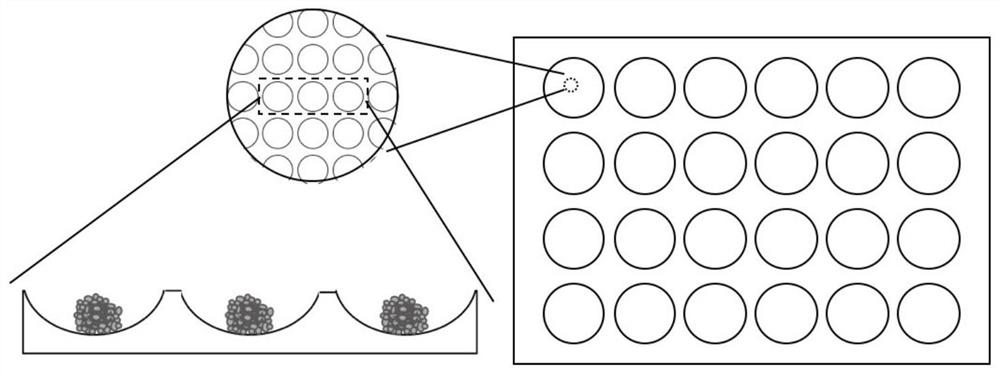

[0078] The present invention provides a preparation method of the above cell cluster preparation device. The device preparation method comprises the following steps:

[0079] 1) Using etching or photolithography to fabricate a template with micro-pattern cavities arranged in an array;

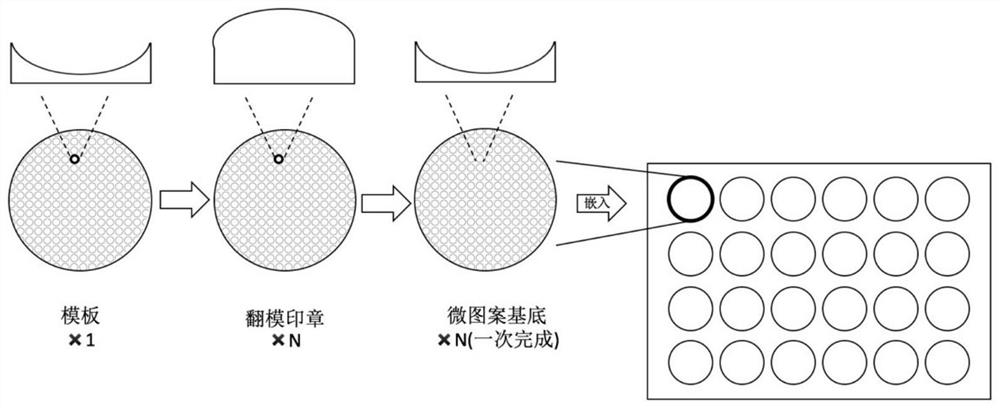

[0080] 2) Using the mold forming method, inject liquid or semi-solid overmolding material into the template, and peel it off from the template after solidification and molding to obtain the overmolding stamp;

[0081] 3) Mix the base material with the cross-linking agent (perform a vacuum operation to remove air bubbles), place the mold stamp in the above mixture, and solidify and form;

[0082] 4) peeling off the overmolding stamp from the above-mentioned molding material, or removing the overmolding stamp from the above-mentioned molding material by chemical or physical methods, to obtain a substrate with micro-pattern cavities arranged in an array;

[0083]5) Fix the substrate in the micro...

Embodiment 1

[0121] Example 1 The method of making a cell cluster preparation device with a degradable overturned mold stamp

[0122] 1. Preparation of micrographic templates

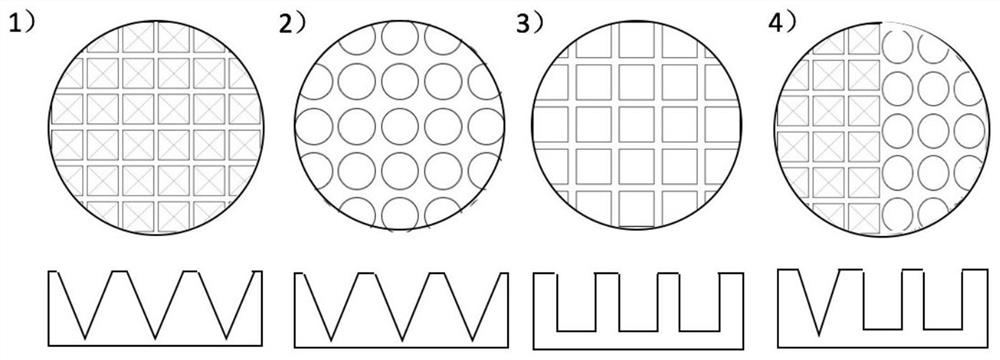

[0123] The micrographic template is made of photolithographic polymethyl methacrylate to prepare a circular template with an overall diameter of 3 cm. The template is an inverted cone-shaped array containing 1500 micro cavities. The distance between adjacent cavities is 200 μm. The figure is an inverted cone with a square upper surface, and the upper surface area is 0.25mm 2 , with a depth of 500 μm.

[0124] 2. Preparation of biodegradable stamps

[0125] The mold stamp is made of agar material. Agar solution with a concentration of 5% is used, dissolved under high temperature and high pressure, poured into the micrographic template while it is hot, and 2ml of agar is poured each time, and vacuum is used to remove air bubbles before the agar solution is solidified. After the agar has cooled and solidified, care...

Embodiment 2

[0132] Example 2 The method of making a cell cluster preparation device with a non-degradable mold stamp

[0133] 1. Preparation of micrographic templates

[0134] The micrographic template is made of etched polymethyl methacrylate to prepare a circular template with an overall diameter of 3 cm. The template is an inverted cone-shaped array containing 1500 micro cavities, and the distance between adjacent cavities is 200 μm. The figure is an inverted cone with a square upper surface, and the upper surface area is 0.25mm 2 , with a depth of 500 μm.

[0135] 2. Preparation of non-degradable flip stamps

[0136] The non-degradable flip stamp is made of silicone material. Mix the silica gel matrix (the main components are vinyl silicone oil and silicon dioxide) with the cross-linking agent (the main component is hydrogen-containing silicone oil) at a volume ratio of 1:1, and quickly pour it onto the template and press it hard to ensure that the material completely covers the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com