Cellulose carbon aerogel for adsorbing oil pollutants

A carbon airgel and pollutant technology, which is applied in the direction of airgel preparation, hydrocarbon oil treatment, biofuel, etc., can solve the problem of low adsorption efficiency, achieve the effect of large adsorption capacity, low preparation cost, and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Put 7.8433g of glucose and 12.1567g of choline chloride into a small beaker, heat and stir in a water bath at 80°C for 2h;

[0032] (2) Mix the deep eutectic solvent in step (1) with 180 g of solution state NMMO·H 2 O mixed and stirred for 30min.

[0033] (3) Mix 6 g of cellulose and 0.12 g of ascorbic acid with the solvent obtained in step (1), put them into a double-layer glass reactor, and stir at -0.1 Pa at 80° C. for 1 h until it becomes an amber liquid.

[0034] (4) Pour the solution obtained in step (3) into a mold, and solidify at room temperature for 1 day, dissolve the solvent prepared in step (2) with deionized water for 2 days, and place the obtained hydrogel in a freeze dryer In 2d, cellulose airgel was obtained;

[0035] Tests show that the prepared cellulose airgel has almost no hydrophobicity, poor adsorption capacity for oil pollutants and organic solvents, and cannot achieve the effect of oil-water separation.

Embodiment 2

[0037] (1) At 80°C, 200g NMMO·H 2 O dissolves in a liquid state.

[0038] (2) Mix 6 g of cellulose and 0.12 g of ascorbic acid with the solvent obtained in step (1), put them into a double-layer glass reactor, and stir at -0.1 Pa at 100° C. for 1.5 h until an amber liquid is formed.

[0039] (3) Pour the solution obtained in step (2) into the mold and solidify at room temperature for 1 day, and dissolve the NMMO·H in step (1) with deionized water 2 O for 2d, the obtained cellulose hydrogel.

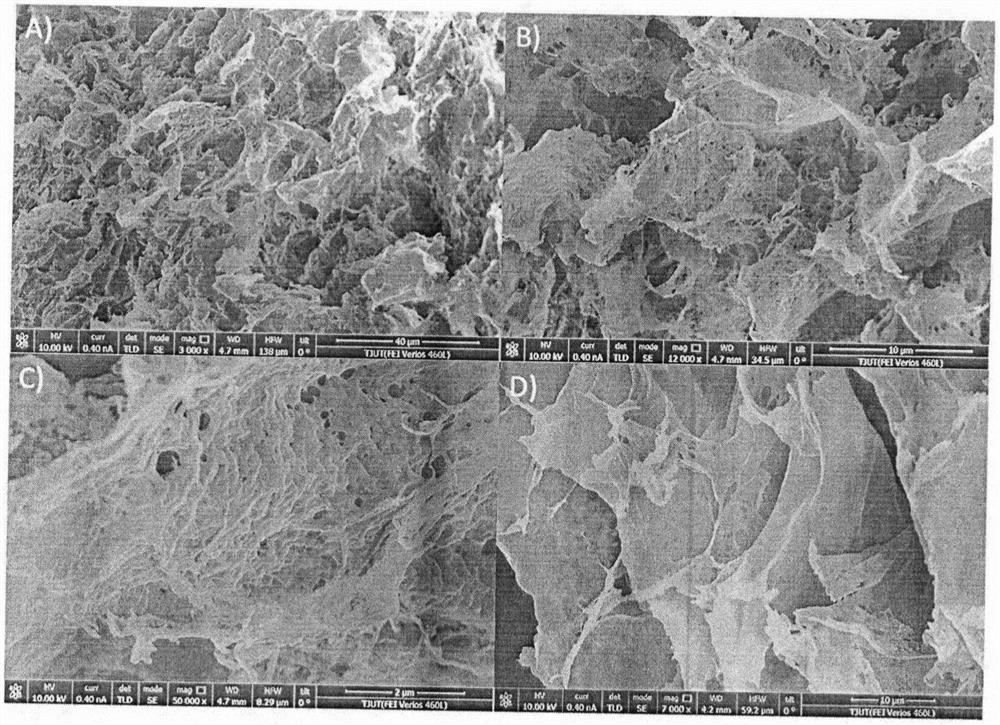

[0040] (4) Place in a freeze dryer for 2 days, and finally heat the airgel to 450° C. at 5° C. / min in an argon atmosphere, keep it warm for 2 hours, and cool to room temperature with the furnace to obtain cellulose.

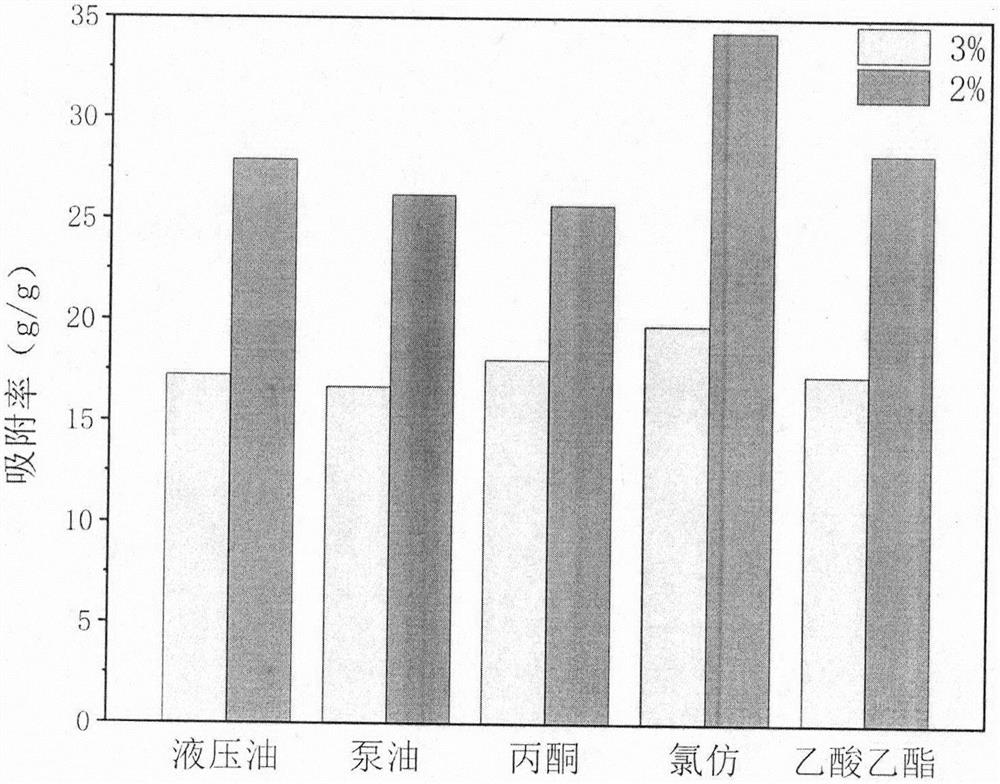

[0041] The test shows that the prepared cellulose carbon airgel has extremely low adsorption performance to oil pollutants and organic solvents, and its hydrophobicity is very poor. Its 5min adsorption value is about 2-3g / g, and its adsorption capacity to oil is very poor ...

Embodiment 3

[0043] (1) Put 7.8433g of glucose and 12.1567g of choline chloride into a small beaker, heat and stir in a water bath at 80°C for 2 hours;

[0044] (2) Mix the deep eutectic solvent in step (1) with 180 g of solution state NMMO·H 2 O mixed and stirred for 30min.

[0045] (3) Mix 6 g of cellulose and 0.12 g of ascorbic acid with the solvent obtained in step (2), put them into a double-layer glass reactor, and stir at -0.1 Pa at 80° C. for 1 h until it becomes an amber liquid.

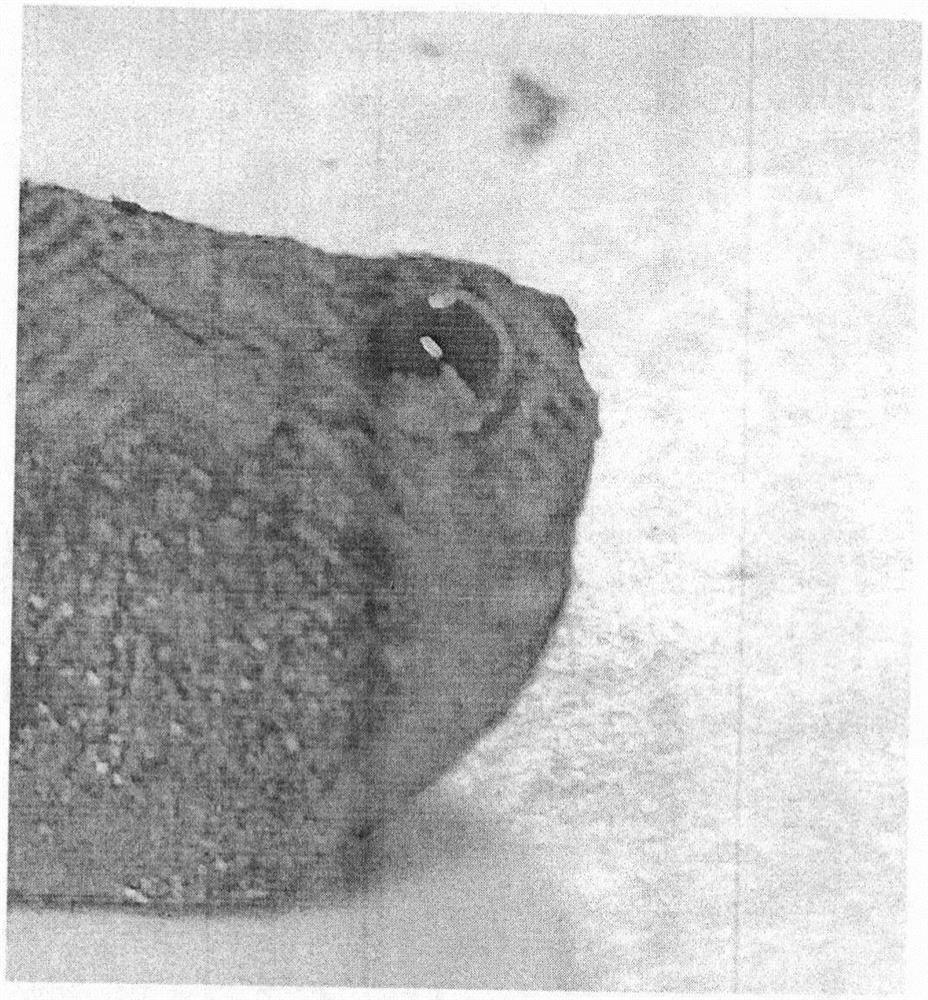

[0046] (4) Pour the solution obtained in step (3) into the mold and solidify at room temperature for 1 d, and dissolve the solvent prepared in step (2) with deionized water for 2 d to obtain a hydrogel.

[0047] (5) Dry the cellulose hydrogel in step (4) in a freeze dryer for 2 days to obtain cellulose aerogel, and finally heat the aerogel to 450 °C at 5°C / min under an argon atmosphere. ℃, keep warm for 2 hours, and cool down to room temperature with the furnace to obtain cellulose.

[0048] The test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption value | aaaaa | aaaaa |

| Adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com