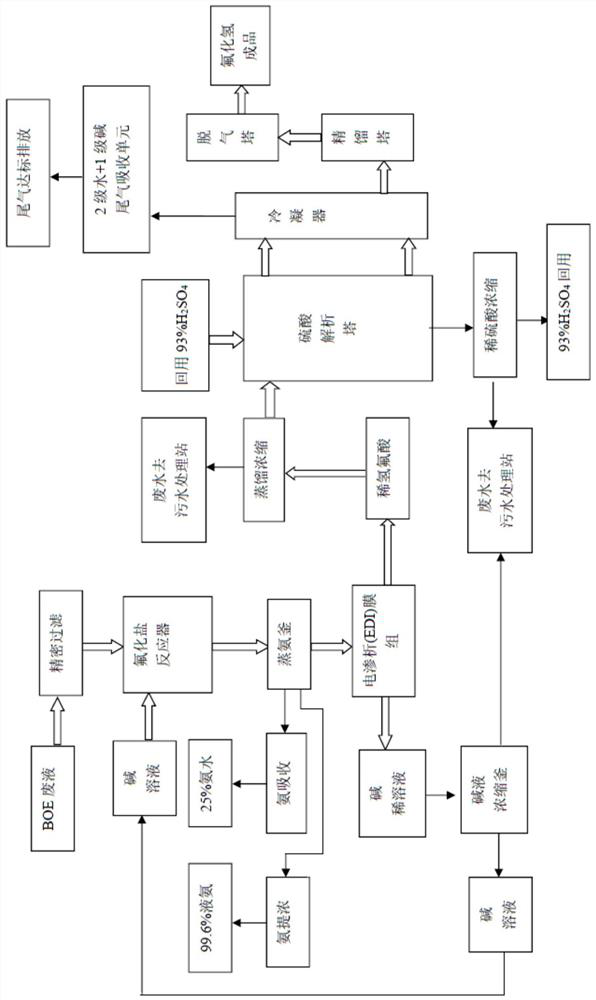

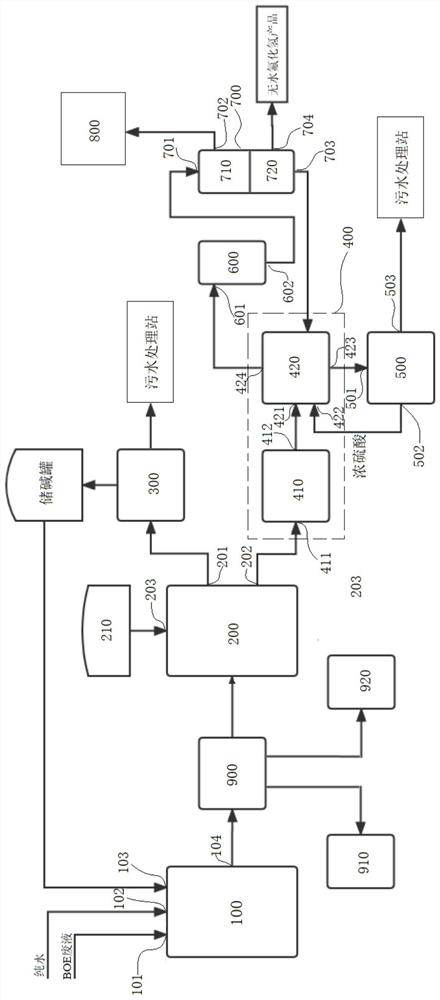

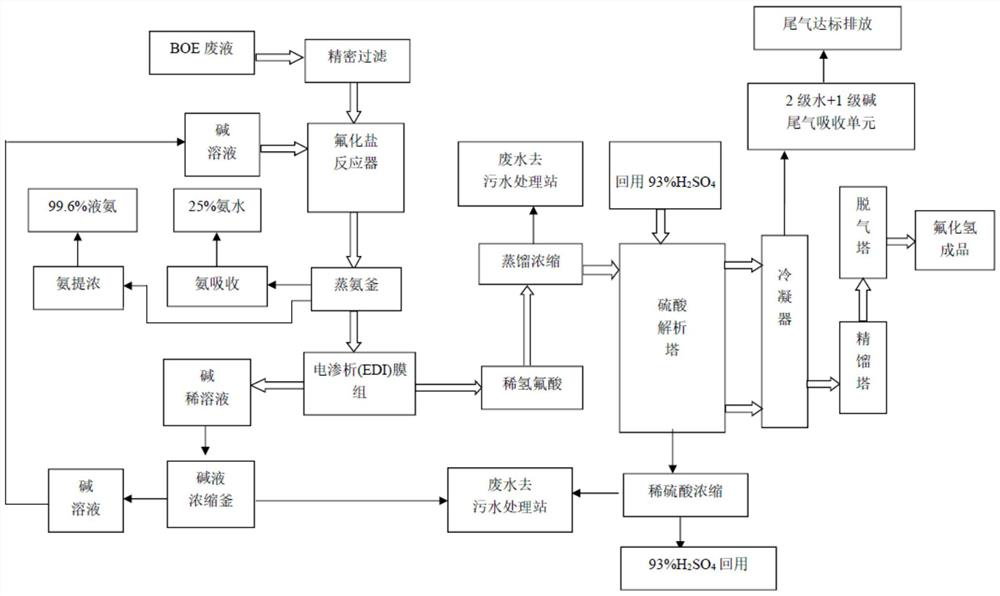

Method and device for preparing hydrogen fluoride from BOE waste liquid

A hydrogen fluoride, waste liquid technology, applied in the directions of hydrogen fluoride, fluorine/hydrogen fluoride, chemical instruments and methods, etc., to achieve the effects of improving efficiency, reasonable process design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] After completely reacting 998.6g of BOE waste liquid with 305.5g of potassium hydroxide solution, it was introduced into the electrodialysis experimental equipment, and the recorded data were as follows:

[0050]

[0051]According to the calculation of the experimental data, it can be seen that the efficiency of electrodialysis separation of hydrofluoric acid in this experiment is 96.4%.

Embodiment 2

[0053] Put 1000kg of BOE waste liquid and 306kg of potassium hydroxide solution into the potassium fluoride reactor for reaction. After the reaction is complete, the reaction solution is introduced into the ammonia distillation kettle, and the ammonia gas is stripped. Lead the remaining reaction solution into the electrodialysis (EDI) membrane group, and decompose it into dilute hydrofluoric acid solution and dilute potassium hydroxide solution; among them, the electrode solution for bipolar membrane electrodialysis is potassium hydroxide, with a concentration of 1.0mol / L ;The current density is 800A / M 2 . Output when the concentration of dilute hydrofluoric acid is 10%. After the reaction solution is decomposed by electrodialysis, when the potassium fluoride concentration is reduced to 5%, it is output from the electrodialysis membrane group, concentrated to 10-25wt%, and then returned to the electrodialysis membrane group. The dilute potassium hydroxide solution is introdu...

Embodiment 3

[0058] Put 1000kg of BOE waste liquid and 306kg of potassium hydroxide solution into the potassium fluoride reactor for reaction. After the reaction is complete, the reaction solution is introduced into the ammonia distillation kettle, and the ammonia gas is stripped. Lead the remaining reaction solution into the electrodialysis (EDI) membrane group, and decompose it into dilute hydrofluoric acid solution and dilute potassium hydroxide solution; among them, the electrode solution of bipolar membrane electrodialysis is potassium hydroxide with a concentration of 0.5mol / L ;The current density is 700A / M 2 . Output when the concentration of dilute hydrofluoric acid is 17%. After the reaction solution is decomposed by electrodialysis, when the potassium fluoride concentration is reduced to 5%, it is output from the electrodialysis membrane group, concentrated to 10-25wt%, and then returned to the electrodialysis membrane group. The dilute potassium hydroxide solution is introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com