Method for producing compound fertilizer by slurry mixing method

A compound fertilizer and slurry technology, applied in nitrogen fertilizer, potash fertilizer, phosphate fertilizer, etc., can solve the problems of large steam consumption, troublesome cleaning, blocked nozzles, etc., to reduce steam consumption, improve cooling efficiency, and improve the effect of ball forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

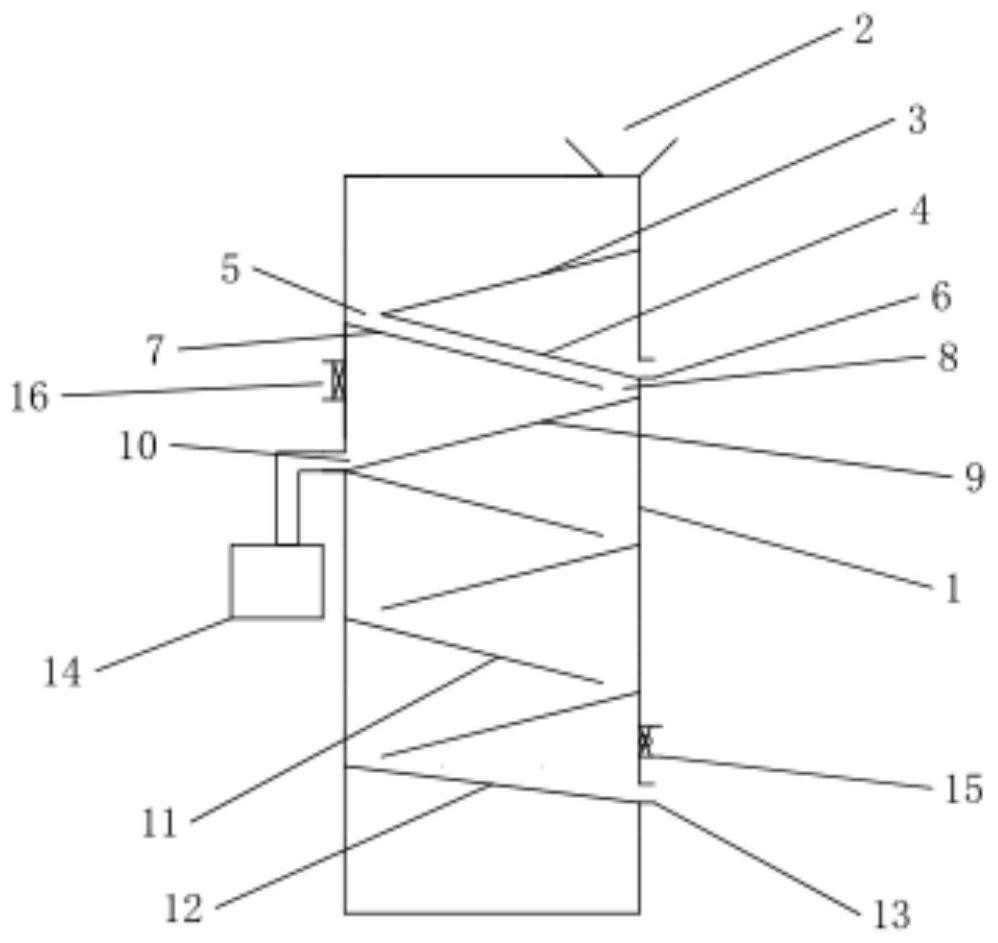

[0056] A method for producing compound fertilizer by slurry mixing method, comprising the following steps:

[0057] 1) The solid raw materials ammonium chloride, monoammonium phosphate, and potassium chloride are sent to the granulator in proportion after being weighed, and the liquid raw materials liquid ammonia, sulfuric acid solution, and monoammonium sulfate are respectively sent to the granulator in proportion solution, and feed steam for granulation to obtain material granules; wherein, the mass ratio of ammonium chloride, monoammonium phosphate, and potassium chloride is 1:1:5, and the amount of liquid ammonia added is the sum of the mass of solid raw materials 1%, the addition of sulfuric acid solution is 0.5% of the sum of the solid raw materials quality; the mass fraction of the sulfuric acid solution is 50%; the addition of the monoammonium phosphate solution is 1% of the sum of the solid raw materials quality;

[0058] 2) Drying, cooling, and sieving the material p...

Embodiment 2

[0061] A method for producing compound fertilizer by slurry mixing method, comprising the following steps:

[0062] 1) The solid raw materials ammonium chloride, monoammonium phosphate, and potassium chloride are sent to the granulator in proportion after being measured and weighed, and the liquid raw materials liquid ammonia, sulfuric acid solution, and monoammonium phosphate are respectively sent to the granulator in proportion solution, and feed steam for granulation to obtain material granules; wherein, the mass ratio of ammonium chloride, monoammonium phosphate, and potassium chloride is 1:5:1, and the amount of liquid ammonia added is the sum of the mass of solid raw materials 5%, the addition of sulfuric acid solution is 1% of the sum of the mass of solid raw materials; the mass fraction of sulfuric acid solution is 80%; the addition of the monoammonium phosphate solution is 10% of the sum of the mass of solid raw materials;

[0063] 2) Drying, cooling, and sieving the ...

Embodiment 3

[0066] A method for producing compound fertilizer by slurry mixing method, comprising the following steps:

[0067] 1) The solid raw materials ammonium chloride, monoammonium phosphate, and potassium chloride are sent to the granulator in proportion after being measured and weighed, and the liquid raw materials liquid ammonia, sulfuric acid solution, and monoammonium phosphate are respectively sent to the granulator in proportion solution, and feed steam for granulation to obtain material granules; wherein, the mass ratio of ammonium chloride, monoammonium phosphate, and potassium chloride is 1:5:1, and the amount of liquid ammonia added is the sum of the mass of solid raw materials 5%, the addition of sulfuric acid solution is 1% of the sum of the solid raw materials; the mass fraction of sulfuric acid solution is 80%; the mass fraction of the monoammonium phosphate solution is 80%, the addition of the monoammonium phosphate solution 5% of the sum of the mass of solid raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com