Nanoparticle catalyst with ultrathin platinum metal layer and preparation method of of nanoparticle catalyst

A platinum group metal, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of time-consuming, unsuitable for industrialization, and achieve high safety, easy operation and scale-up The effect of mild production and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

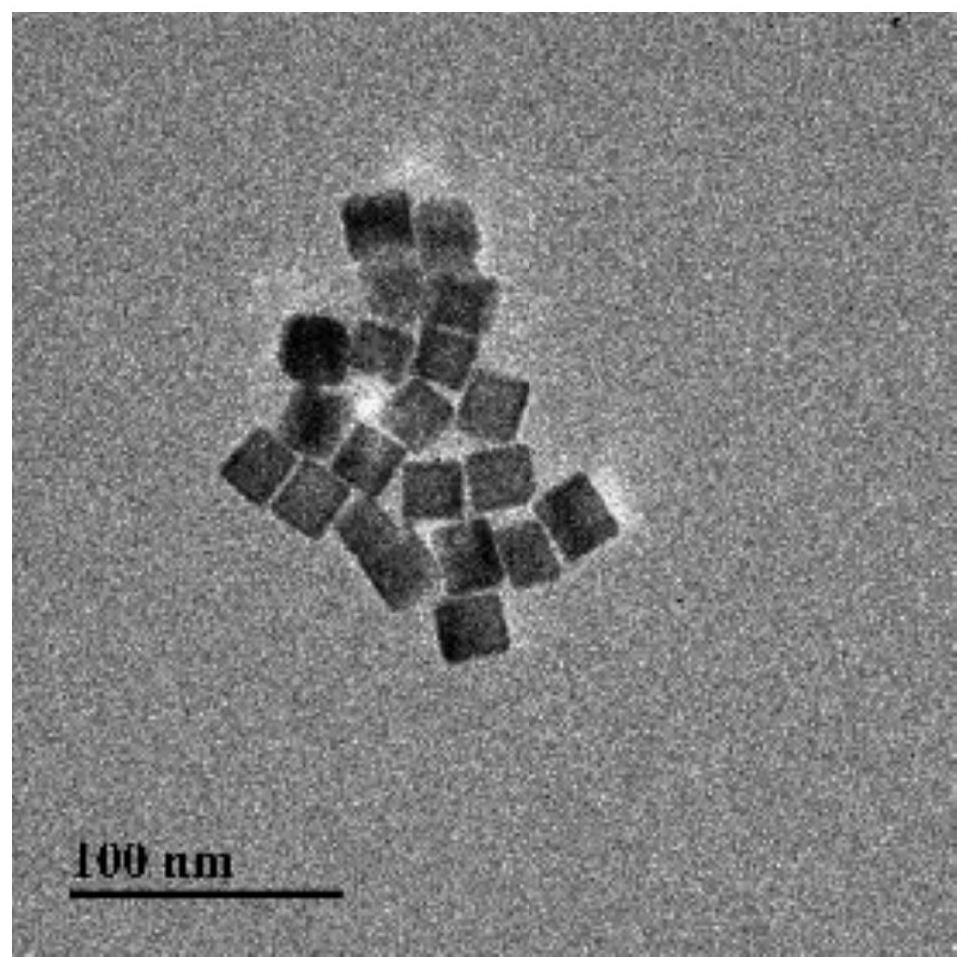

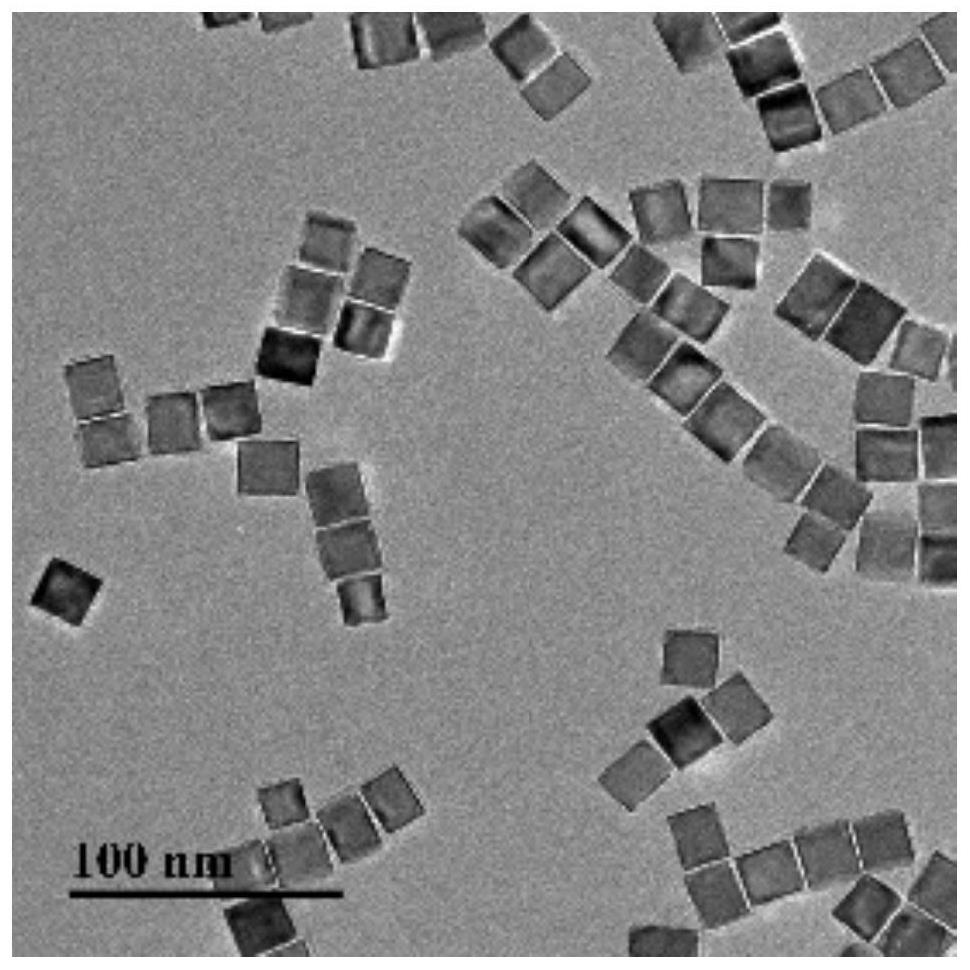

[0037] The preparation method of polyvinylpyrrolidone-modified palladium cubes: add 105mgPVP, 600mg potassium bromide and 60mg ascorbic acid into 8mL deionized water at 80°C, then add 3mL 19mg / mL sodium chloropalladate aqueous solution, react for 3 hours and collect by centrifugation Finally, polyvinylpyrrolidone-modified palladium cubes are obtained.

[0038] The preparation method of polyvinylpyrrolidone-modified palladium octahedron: add 105mgPVP to 7mL deionized water at 80°C, add 0.1mL formaldehyde and 0.34mL palladium cube obtained above in advance, and then add 3mL 10mg / mL sodium chloropalladate The aqueous solution was reacted in deionized water at 60°C for 3 hours and collected by centrifugation.

[0039] Preparation method of polyvinylpyrrolidone-modified palladium icosahedron: add 1 mL of 15.5 mg / mL sodium chloropalladate solution to 2 mL of 80 mg / mL PVP ethylene glycol solution, and react at 130° C. for 1 h. Then collected by centrifugation.

Embodiment 1

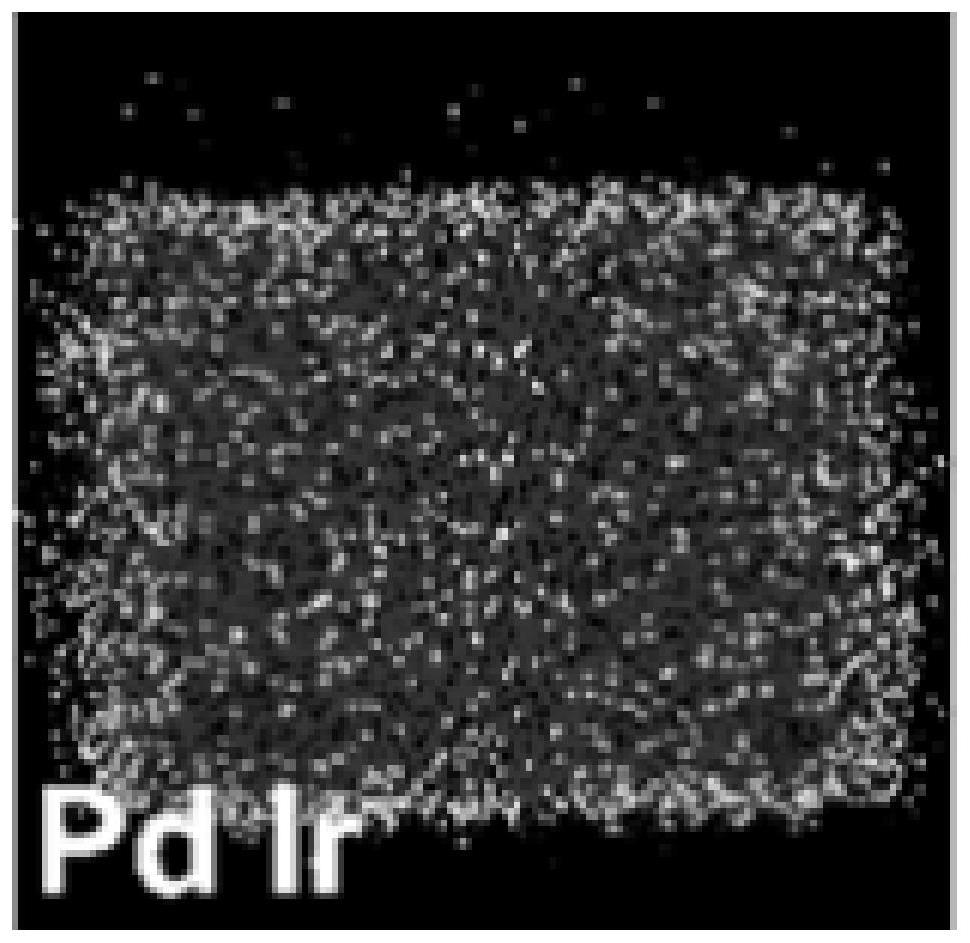

[0040] Example 1: Preparation of Nanoparticle Catalysts with Ultrathin Iridium Nanolayers

[0041]1. Disperse polyvinylpyrrolidone-modified palladium octahedra with a particle size of 12nm in ethylene glycol to prepare a 1.8mg / mL solution, take 0.3mL of the solution, 50mg PVP, and 50mg KBr and disperse them in 7mL triethylene diethylene glycol Alcohol, ultrasonically mixed thoroughly. The solution was heated to 180°C and kept stirring for 30 min.

[0042] 2. Dissolve iridium chloride in ethylene glycol solution and prepare a solution with a concentration of 4mg / mL, take 0.123mL of the solution and add it to the above solution at 180°C, and react for 4h.

[0043] 3. After the reaction time ends, wash 3 times with ultrapure water and acetone, and dry to obtain the nanoparticle catalyst of the ultrathin iridium nano-layer after being centrifuged at 17500 rpm.

Embodiment 2

[0044] Example 2: Preparation of Nanoparticle Catalysts with Ultrathin Iridium Nanolayers

[0045] 1. Disperse polyvinylpyrrolidone-modified palladium cubes with a particle size of 53nm in diethylene glycol to prepare a 2.4mg / mL solution, take 0.2mL of the solution, 150mg PVP, and 100mg KBr and disperse them in 7mL tetraethylene glycol Alcohol, ultrasonically mixed thoroughly. The solution was heated to 190°C and kept stirring for 30 min.

[0046] 2. Dissolve sodium hexachloroiridate in ethylene glycol solution and make a solution with a concentration of 4mg / mL, take 0.221mL of the solution and add it to the above solution at 190°C, and react for 7h.

[0047] 3. After the reaction time ends, wash 3 times with ultrapure water and acetone, and dry to obtain the nanoparticle catalyst of the ultrathin iridium nano-layer after being centrifuged at 17500 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com