Composite emulsion containing walnut oil and dihydromyricetin and preparation method thereof

A technology of dihydromyricetin and composite emulsion, applied in the field of composite emulsion, can solve the problems of thin emulsifier interface thickness, high light penetration, large specific surface area, etc., to improve water solubility, prolong shelf life, and prepare method Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A compound emulsion containing walnut oil and dihydromyricetin is composed of the following components by mass: 0.05% dihydromyricetin, 1% walnut oil, 0.5% soybean lecithin, 10% sodium caseinate, whey protein 2%, hydrophobic silica 0.5%, deionized water 85.95%.

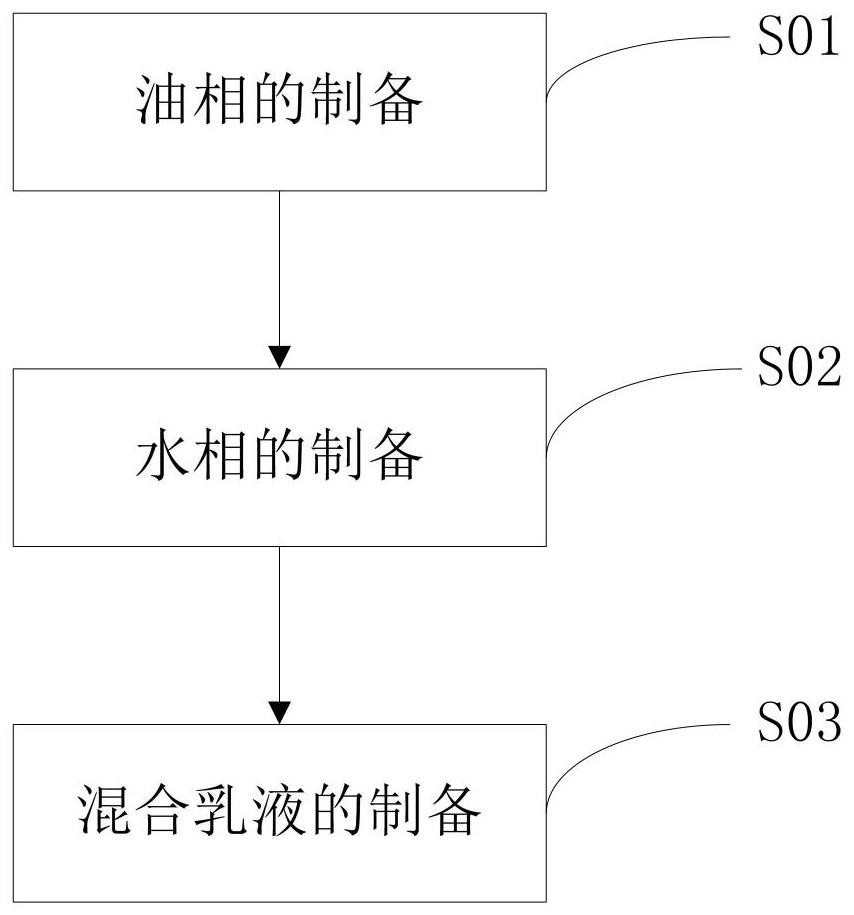

[0033] refer to figure 1 , a kind of preparation method containing the composite emulsion of walnut oil and dihydromyricetin, comprises the following steps:

[0034] Preparation of S01 oil phase: Weigh 0.05g of dihydromyricetin and 1g of walnut oil, add walnut oil and dihydromyricetin into a stirring pot in order to mix and dissolve, and stir until there are no obvious particles under the naked eye to obtain oil Mutually;

[0035] Preparation of S02 water phase: Weigh 0.5g soybean lecithin, 10g sodium caseinate, 2g whey protein, 0.5g hydrophobic silicon dioxide and 85.95g deionized water, add the deionized water into the emulsification pot, and Add soybean lecithin, sodium caseinate, whey protein, and hydrop...

Embodiment 2

[0039] A compound emulsion containing walnut oil and dihydromyricetin is composed of the following components by mass: 1% dihydromyricetin, 7% walnut oil, 10% egg yolk lecithin, 2% sodium caseinate, whey protein 0.5%, hydrophobic silica 0.5%, deionized water 79%.

[0040] refer to figure 1 , a kind of preparation method containing the composite emulsion of walnut oil and dihydromyricetin, comprises the following steps:

[0041] Preparation of S01 oil phase: Weigh 1g of dihydromyricetin and 7g of walnut oil, add walnut oil and dihydromyricetin in a stirring pot in sequence to mix and dissolve, and stir until there are no obvious particles under the naked eye to obtain the oil phase ;

[0042]Preparation of S02 water phase: Weigh 10g egg yolk lecithin, 2g sodium caseinate, 0.5g whey protein, 0.5g hydrophobic silicon dioxide and 79g deionized water, add deionized water into the emulsification pot, Add soybean lecithin, sodium caseinate, whey protein, and hydrophobic silicon di...

Embodiment 3

[0046] A compound emulsion containing walnut oil and dihydromyricetin is composed of the following components by mass: 2% dihydromyricetin, 15% walnut oil, 3% hydrogenated lecithin, 0.5% sodium caseinate, whey protein 10%, Hydrophobic Silica 1%, Deionized Water 68.5%.

[0047] refer to figure 1 , a kind of preparation method containing the composite emulsion of walnut oil and dihydromyricetin, comprises the following steps:

[0048] Preparation of S01 oil phase: Weigh 2g of dihydromyricetin and 15g of walnut oil, add walnut oil and dihydromyricetin in a stirring pot in turn to mix and dissolve, and stir until there are no obvious particles under the naked eye to obtain the oil phase ;

[0049] Preparation of S02 water phase: Weigh 3g of hydrogenated lecithin, 0.5g of sodium caseinate, 10g of whey protein, 1g of hydrophobic silicon dioxide and 68.5g of deionized water, add the deionized water into the emulsification pot, and place Add soybean lecithin, sodium caseinate, whey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com