Fabric texture matt glaze, matt frit, ceramic tile, application and preparation method

A matte glaze and texture technology, applied in the field of ceramic tiles, can solve the problems of monotonous glaze and achieve the effect of solving light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the matte frit of cloth art texture matte glaze comprises the following steps:

[0039] The raw materials of the matt frit are centrifugally stirred evenly, and then transferred to a furnace at 1535°C-1555°C for heat preservation, so that the matte frit melt is homogenized, and then quenched in water and dried to obtain a matt frit.

[0040] A fabric texture matte glaze, comprising: 60-80% base glaze and 20-40% matte frit;

[0041] The matte frit is the matte frit of the above-mentioned fabric texture matte glaze.

[0042] The basic glaze of this solution can be replaced by a known glaze, and when combined with a matte frit, the glaze can be made into a ceramic tile with a matte texture, a texture of fabric, anti-fouling, anti-slip, acid and alkali corrosion resistance, wear resistance and high hardness.

[0043] More preferably, according to mass percentage, its raw materials include: 0-20% ultrawhite albite, 15-20% ultrawhite potassium felds...

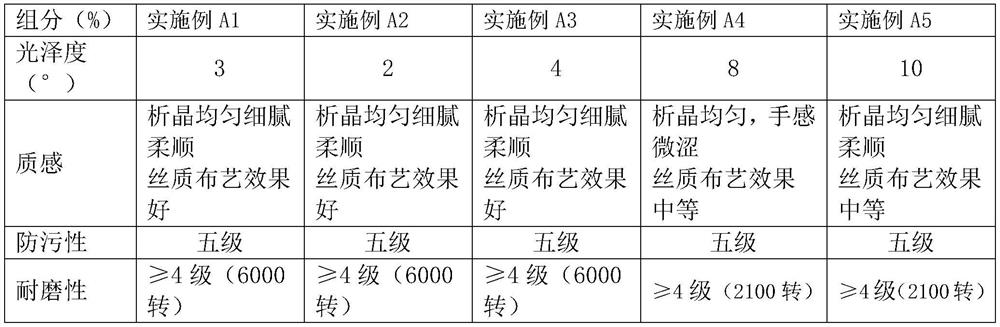

Embodiment A

[0064] Preparation method of fabric texture matte tile

[0065] To prepare the top glaze:

[0066] The surface glaze is selected from the existing formula, and the raw materials include: 7 parts of air-knife soil, 34 parts of potassium feldspar, 11 parts of albite, 15 parts of burnt soil, 10 parts of quartz powder, 12 parts of calcined alumina, in parts by weight, 3 parts of dolomite, 8 parts of frit A, 8 parts of zirconium silicate, add water to account for 40% of the mass, after ball milling, sieving, iron removal, control the flow rate of ball glaze slurry for 50-80 seconds, specific gravity 1.88, 325 mesh sieve The remaining 0.5-1.0g / specific gravity cup. The top glaze is applied on the surface of the green body through the glaze pouring process to form a top glaze layer.

[0067] Preparation of fabric texture matte glaze:

[0068] (1) The raw materials of the matt frit are centrifugally stirred evenly, and then transferred to a melting furnace at 1535° C. for 100 minut...

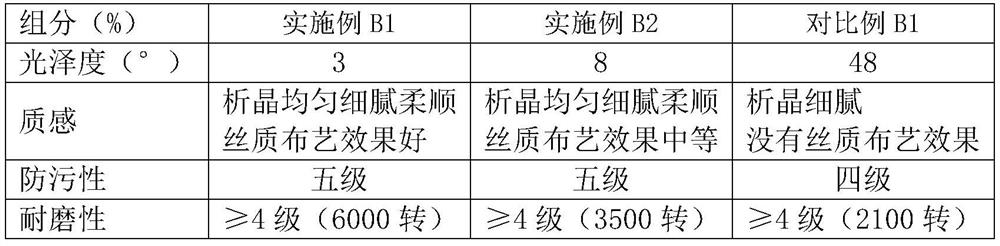

Embodiment B

[0081] 1. Prepare the top glaze:

[0082] The present embodiment B1-B2 and comparative example B1 select the surface glaze, according to parts by weight, including: 7 parts of air knife soil, 34 parts of potassium feldspar, 11 parts of albite, 15 parts of burnt soil, 10 parts of quartz powder, calcined 12 parts of alumina, 3 parts of dolomite, 8 parts of frit A, and 8 parts of zirconium silicate. Add water to account for 40% of the mass. After ball milling, sieving, and iron removal, the flow rate of the ball glaze slurry is controlled for 50-80 seconds, the specific gravity is 1.88, and the remaining 0.5-1.0g / specific gravity cup is 325 mesh sieve. The top glaze is applied on the surface of the green body through the glaze pouring process to form a top glaze layer.

[0083] 2. Prepare the inkjet layer, apply the textured inkjet layer on the surface of the glaze layer by inkjet printing.

[0084] 3. Prepare the color-boosting glaze layer, which is applied to the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com