Compact oil reservoir CO2 flooding multi-scale channeling control system and preparation method

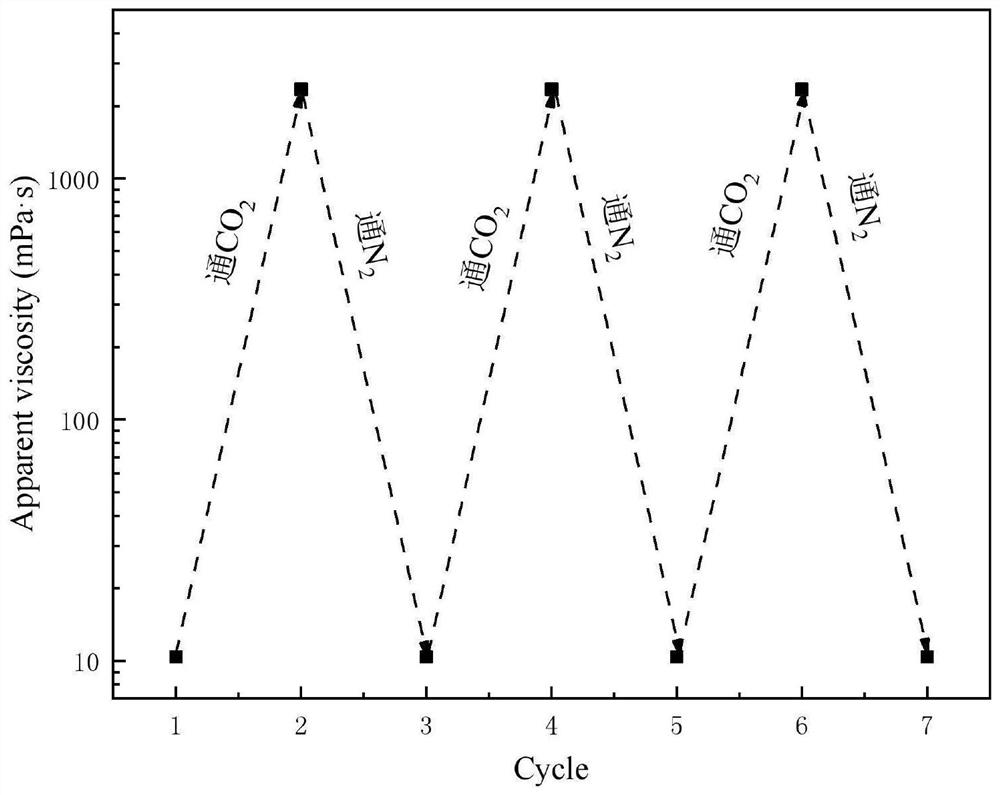

A tight oil reservoir, multi-scale technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high concentration of switch-type dispersants, low applicable temperature, etc., and achieve good response reversibility, fluidity The effect of increased control and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Nanoscale CO 2 Preparation of responsive worm-like micelles

[0039] Dissolve N,N-dimethyl oleic acid amidopropyl tertiary amine in deionized water, prepare 200mL N,N-dimethyl oleic acid amidopropyl tertiary amine solution with a concentration of 90mmol / L, and stir at a speed of 300r / Add 18mmol sodium p-styrenesulfonate to the above solution under the condition of 1 min, stop stirring after the solution is uniform, and obtain nanoscale CO 2 Responsive worm-like micellar system.

[0040] 2) Micron level CO 2 Preparation of Responsive Dispersion Gum

[0041] 0.1g of γ-methacryloxypropyltrimethoxysilane modified hydroxylated multi-walled carbon nanotubes were uniformly dispersed in 75mL of deionized water under ultrasonic conditions, and then 20g of Acrylamide, 5g ethylenediaminoethyl methacrylate, 0.5mL ammonium persulfate (concentration 1wt%), 0.5mL sodium bisulfite (concentration 1wt%) and 1mL azobisisobutylamidine hydrochloride (concentration 1wt%) %) and 1mL ...

Embodiment 2

[0046] 1) Nanoscale CO 2 Preparation of responsive worm-like micelles

[0047] Dissolve N,N-dimethyl oleic acid amidopropyl tertiary amine in deionized water, prepare 200mL N,N-dimethyl oleic acid amidopropyl tertiary amine solution with a concentration of 70mmol / L, and stir at a speed of 500r / Add 14 mmol sodium oleate to the above solution under the condition of 1 min, stop stirring after the solution is uniform, and obtain nano-scale CO 2 Responsive worm-like micellar system.

[0048] 2) Micron level CO 2 Preparation of Responsive Dispersion Gum

[0049] 0.07g of γ-methacryloxypropyltrimethoxysilane-modified hydroxylated multi-walled carbon nanotubes were uniformly dispersed in 70mL of deionized water under ultrasonic conditions, and then 20g of Acrylamide, 8g ethylenediaminoethyl methacrylate, 0.6mL ammonium persulfate (concentration 1wt%), 0.6mL sodium bisulfite (concentration 1wt%) and 1.2mL azobisisobutylamidine hydrochloride (concentration 1wt%) and 0.2gN, N-methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com