Preparation process of trelagliptin succinate tablet

A troxagliptin succinate, preparation process technology, applied in the field of preparation of troxagliptin succinate tablets, can solve the problems of easy adhesion and compressibility, prone to splitting, poor compressibility, etc., and achieve good flow and compressibility, ensuring product quality attributes, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

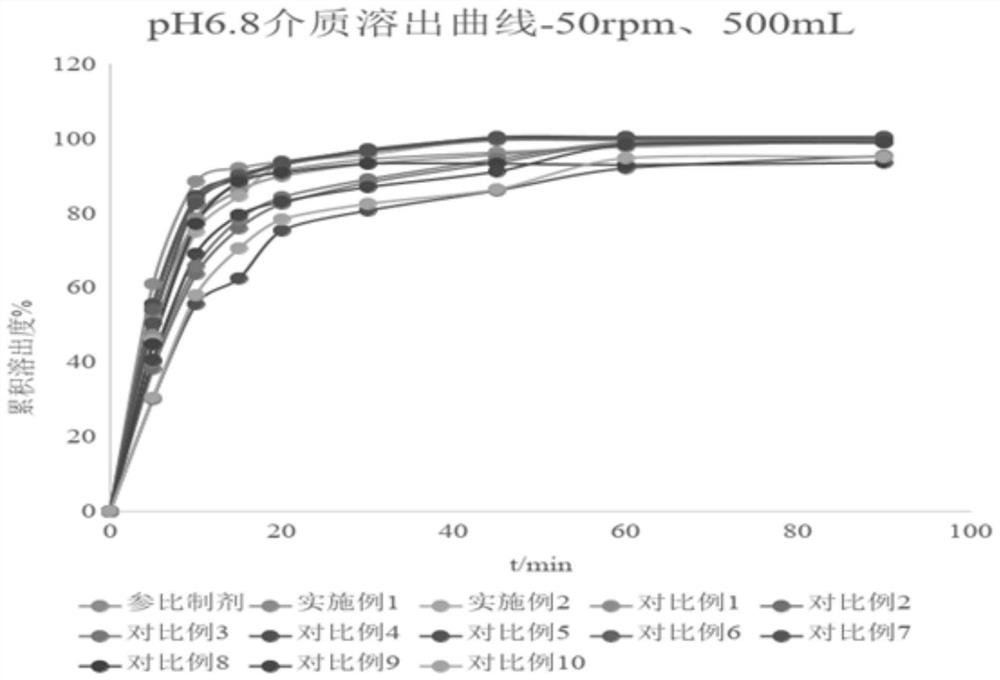

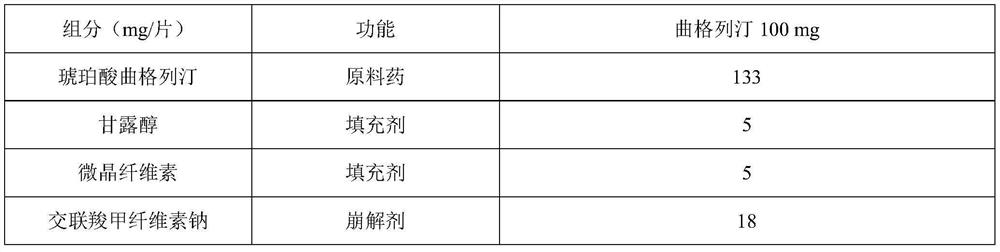

[0025] Tablets are prepared with the formula shown in Table 1, and the specific process is as follows:

[0026] In the first step, mix the prescription amount of trexagliptin succinate with HPC-L:HPMC powder at a ratio of 4:1, dissolve it in water, and make a 0.3% w / w solution of solute.

[0027] The second step is to add the above solution into the spray drying equipment, the air inlet temperature is 160°C, the feeding speed is 5mL / min, the atomization pressure is 0.5MPA, and the dry air source is used for drying and heating. 3 The / h flow rate is transported to the drying room, and the granules are sieved with a granulator in the spray dryer, with a 0.99mm sieve.

[0028] In the third step, the granules obtained by sieving, microcrystalline cellulose, mannitol, and croscarmellose sodium are uniformly mixed in a mixer, and then sodium stearyl fumarate is added for mixing to obtain a tablet-making product. Granules: Using a rotary tablet press, use a 11*5.6mm die to tablet th...

Embodiment 2

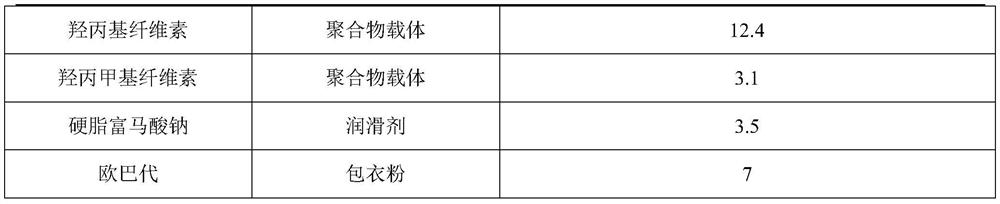

[0033] Prepare tablet with formula shown in table 2, concrete process is as follows:

[0034] In the first step, mix the prescription amount of trexagliptin succinate with HPC-L:HPMC powder at a ratio of 4:1, dissolve it in water, and prepare a solute 3% w / w solution.

[0035] The second step is to add the above solution into the spray drying equipment, the air inlet temperature is 120°C, the feeding speed is 5mL / min, the atomization pressure is 0.5MPa, and the dry air source is used for drying and heating. 3 The / h flow rate is transported to the drying room, and the granules are sieved with a granulator in the spray dryer, with a 0.99mm sieve.

[0036] In the third step, the granules obtained by sieving, microcrystalline cellulose, mannitol, and croscarmellose sodium are uniformly mixed in a mixer, and then sodium stearyl fumarate is added for mixing to obtain a tablet-making product. Granules: Using a rotary tablet press, use a 11*5.6mm die to tablet the granules to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com