A crystallization method for preparing azithromycin with millimeter-scale large particle size

A technology of azithromycin and large particle size, which is applied in the field of crystallization of azithromycin with millimeter-scale large particle size, can solve the problem of high product purity, achieve high product purity, realize industrial production, and have good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

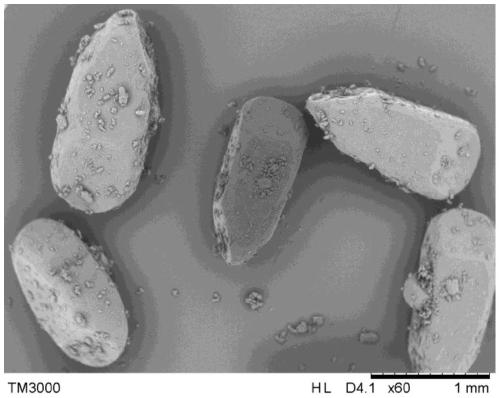

[0026] Add 5g of azithromycin and 10g of acetone into a crystallizer with stirring, heat it to 50°C and keep it warm. After the azithromycin is completely dissolved, add 2.5g of water. After the system is stable, add 0.5% of the total weight of azithromycin Azithromycin crystals are used as crystal seeds , grow crystals at constant temperature for 30 minutes, slowly add 10 g of water dropwise, and the entire dropping time is controlled at about 5 hours, after adding water, filter and dry to obtain the product. The SEM photo of the product is attached figure 2 As shown in the figure, it can be seen from the figure that the particle size of a single crystal product is greater than 1.4 mm, and the particle size distribution of the product is uniform; the bulk density is 0.58g / mL; the angle of repose is 37.2°; the purity of the product detected by liquid phase is 99.7%.

Embodiment 2

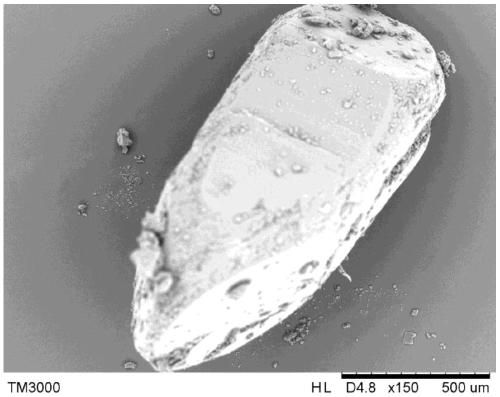

[0028] Add 10g of azithromycin and 50g of acetone into a crystallizer with stirring, keep the temperature at 30°C and keep it warm. After the azithromycin is completely dissolved, add 20g of water. After the system is stable, add azithromycin crystals of 2% of the total weight of azithromycin as crystal seeds , grow crystals at constant temperature for 10 minutes, slowly add 60g of water dropwise, the whole dropping time is controlled at about 10h, after adding water, filter and dry to obtain the product. The SEM photo of the product is attached image 3 As shown, it can be seen from the figure that the particle size of a single crystal product is greater than 1.6 mm, and the particle size distribution of the product is uniform; the bulk density is 0.59g / mL; the angle of repose is 36.5°; the purity of the product detected by liquid phase is 99.8%.

Embodiment 3

[0030] Add 8g of azithromycin and 32g of acetone into the crystallizer with stirring, keep the temperature at 50°C and keep it warm. After the azithromycin is completely dissolved, add 12g of water. After the system is stable, add azithromycin crystals of 1% of the total weight of azithromycin as crystal seeds , grow crystals at constant temperature for 40 minutes, slowly add 40 g of water dropwise, the entire dropwise addition time is controlled at about 8 hours, after adding water, filter and dry to obtain the product. The SEM photo of the product is attached Figure 4 As shown, it can be seen from the figure that the particle size of a single crystal product is greater than 1.5 mm, and the particle size distribution of the product is uniform; the bulk density is 0.60 g / mL; the angle of repose is 37.9°; the purity of the product is 99.8% through liquid phase detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com