Food waste pretreatment coupling power generation system applied to thermal power plant

A technology of catering waste and power generation system, applied in the field of catering waste pretreatment coupled power generation system, can solve the problems of difficult continuous and stable supply of biogas, low daily output of food waste, and high treatment costs, so as to reduce the amount of outbound transportation and ensure sufficient The effect of high utilization and reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

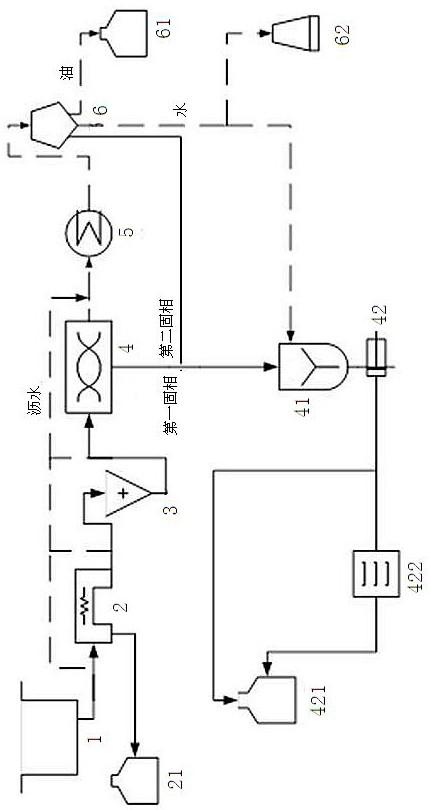

[0024] A food waste pretreatment coupling power generation system applied to a thermal power plant, which consists of: a receiving bin 1, a sorter 2, a crusher 3, a dry-wet separation device 4, a heater 5, a three-phase separator 6, a storage Oil tank 61, mixer 41, conveying device, boiler 421 and drying device 422;

[0025] The receiving bin is arranged underground, and the level of the bin opening is flush with the ground. After the vehicle arrives at the bin opening, the bin cover is opened, and the food waste is unloaded into the bin 1. After the bin cover is closed, the bottom of the bin is arranged The conveyor transports the garbage to the sorting machine, and the food waste sorted by the sorting machine enters the crusher. The crusher 3 can be set to one-stage crushing or multi-stage crushing. After the machine is crushed, it enters the dry-wet separation device, and the dry-wet separation device can be a commonly used screw press or plate-and-frame filter press;

[0...

Embodiment 2

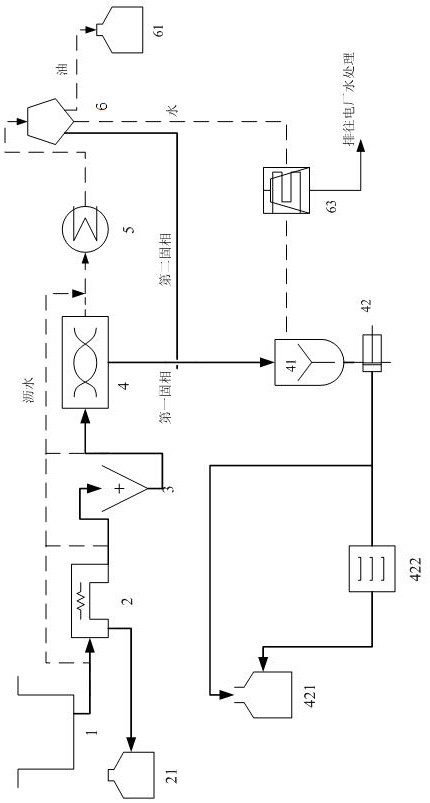

[0029] According to the food waste pretreatment coupling power generation system applied to a thermal power plant described in Embodiment 1, the water separated by the three-phase separator enters the mixer 41 and the waste heat solidification device 62 through the pipeline, and the separated oil enters the to oil storage tank 61.

Embodiment 3

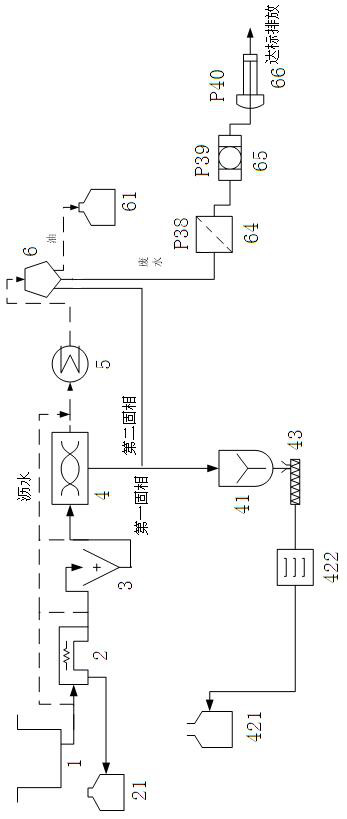

[0031] According to the food waste pretreatment coupling power generation system applied to thermal power plants described in embodiment 1 or 2, the water separated by the three-phase separator enters the waste water concentration and weight reduction device 63, and the separated oil enters the oil storage tank , the concentrated solution concentrated by the waste water concentration and weight reduction device enters the mixer, and the qualified water is discharged to the water treatment system of the power plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com