Preparation method of high-energy composite structure explosive

A technology of composite structure and explosives, which is applied in the direction of explosives processing equipment, explosives, explosives composite components, etc., can solve the problems of slow energy release rate, etc., and achieve the effect of simple process, close contact and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing high-energy composite structure explosives, comprising the following steps:

[0032] Step 1. Prepare 20 mL of Tris buffer solution with a pH of 8.5 to 8.6 and a concentration of 10 mM, and dissolve dopamine hydrochloride in the buffer solution to obtain a dopamine hydrochloride solution with a concentration of 0.4 g / L;

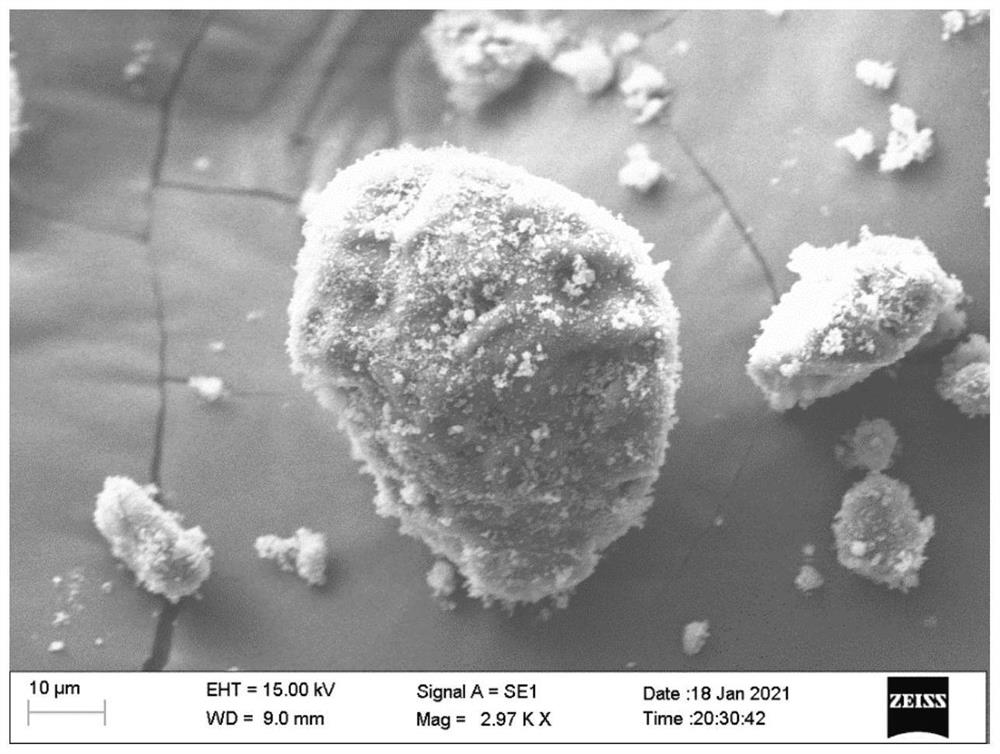

[0033] Step 2: Put 1.4g of RDX in the dopamine hydrochloride solution, stir and mix the dispersion with a magnetic stirrer at a speed of 500RPM for 3 hours, and filter and wash the stirred solution three times with deionized water. Put the cleaned ammonium nitrate explosive in an oven at 50°C for 12 hours to obtain modified RDX;

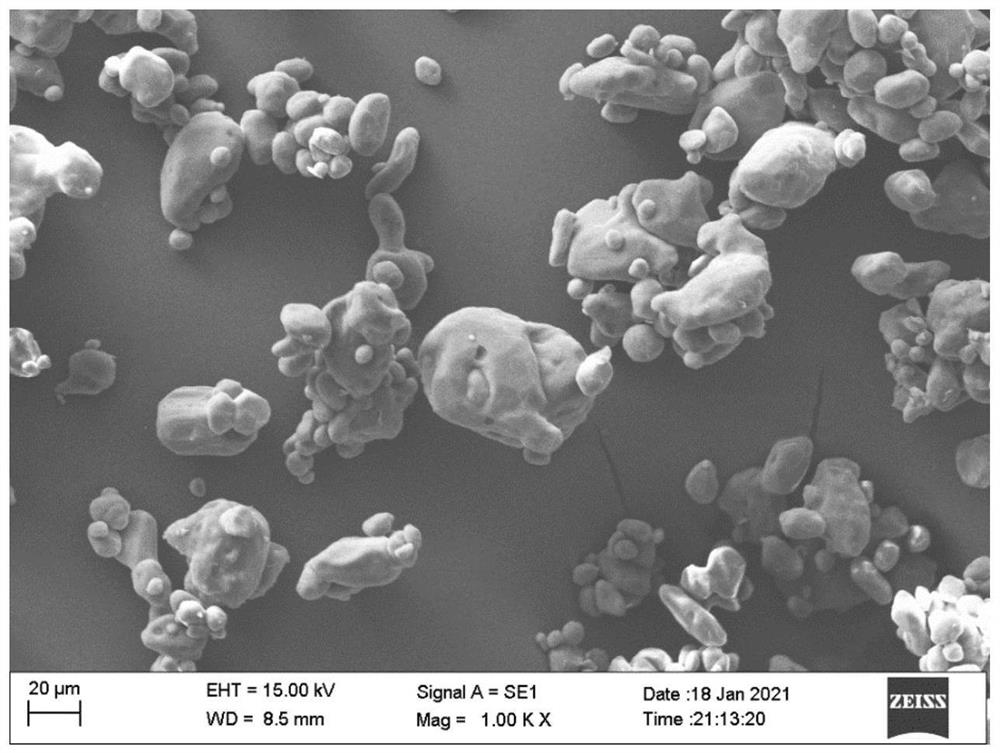

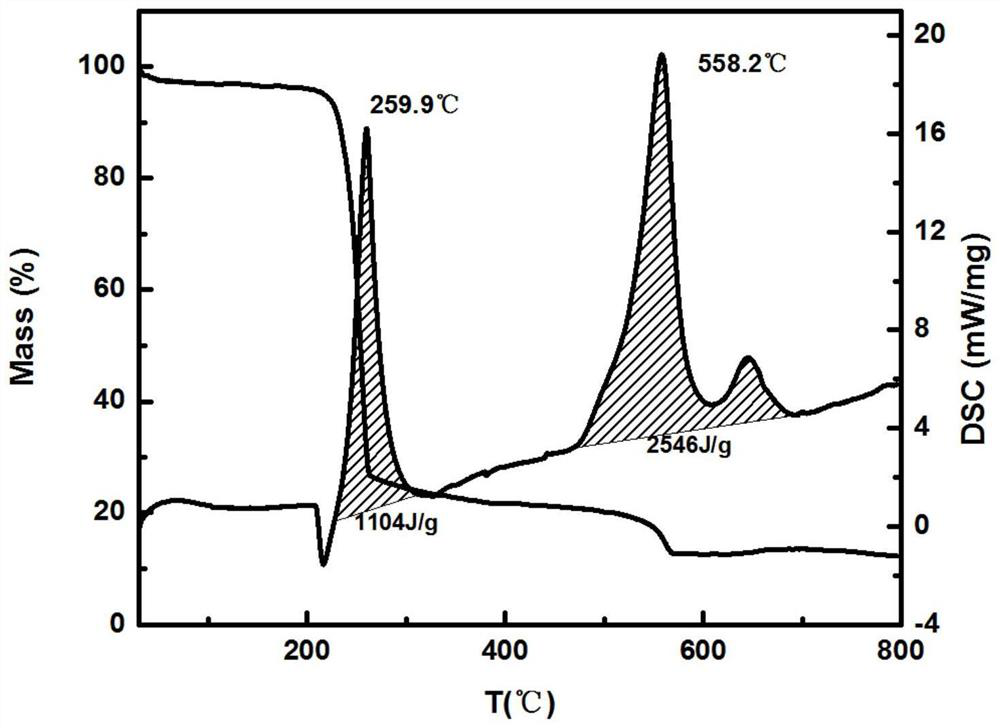

[0034] Step 3: Weigh 0.7g of modified RDX, 0.1g of nano-aluminum powder, and 0.2g of polytetrafluoroethylene into 10mL of alcohol solution, filter out most of the solvent after ultrasonication for 10min, and dry in a vacuum oven for 2h to obtain Composite structure explosive; ultrasonic frequency is 45k...

Embodiment 2

[0038] A method for preparing high-energy composite structure explosives, comprising the following steps:

[0039] Step 1. Prepare 20 mL of Tris buffer solution with a pH of 8.5 to 8.6 and a concentration of 10 mM, and dissolve dopamine hydrochloride in the buffer solution to obtain a dopamine hydrochloride solution with a concentration of 0.4 g / L;

[0040] Step 2: Put 1.4g of RDX in the dopamine hydrochloride solution, stir and mix the dispersion with a magnetic stirrer at a speed of 500RPM for 3 hours, and filter and wash the stirred solution three times with deionized water. Put the cleaned ammonium nitrate explosive in an oven at 50°C for 12 hours to obtain modified RDX;

[0041]Step 3: Weigh 0.7g of modified RDX, 0.12g of nano-aluminum powder, and 0.18g of iron oxide into 10mL of isopropanol solution, filter out most of the solvent after ultrasonication for 10min, and dry in a vacuum oven for 2h to obtain a composite Structural explosives; the frequency of ultrasound is ...

Embodiment 3

[0043] A method for preparing high-energy composite structure explosives, comprising the following steps:

[0044] Step 1: Prepare 50 mL of Tris buffer solution with a pH of 8.5 to 8.6 and a concentration of 10 mM, and dissolve dopamine hydrochloride in the buffer to obtain a dopamine hydrochloride solution with a concentration of 2 g / L;

[0045] Step 2. Put 2g of RDX in the dopamine hydrochloride solution, use a magnetic stirrer to stir and mix the dispersion at a speed of 500RPM for 3 hours, and filter and wash the stirred solution three times with deionized water. The cleaned ammonium nitrate explosive was placed in an oven at 50°C for 12 hours to obtain modified RDX;

[0046] Step 3: Weigh 0.7g of modified RDX, 0.12g of nano-aluminum powder, and 0.2g of polytetrafluoroethylene into 10mL of isopropanol solution, filter out most of the solvent after ultrasonication for 10min, and dry in a vacuum oven for 2h. Obtain composite structure explosive; the frequency of ultrasound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com