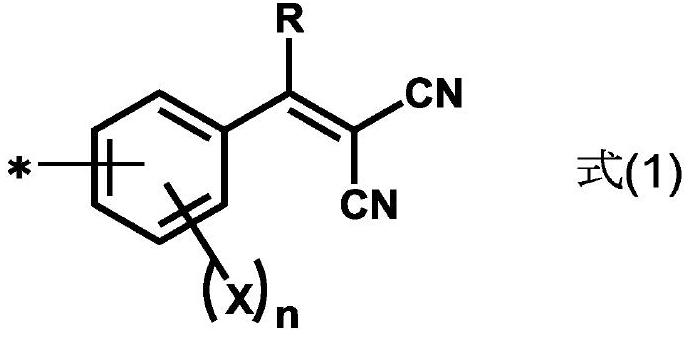

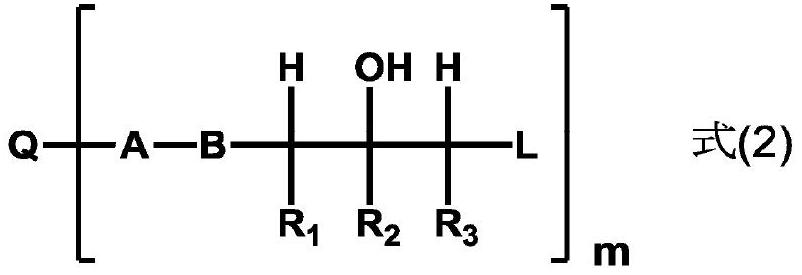

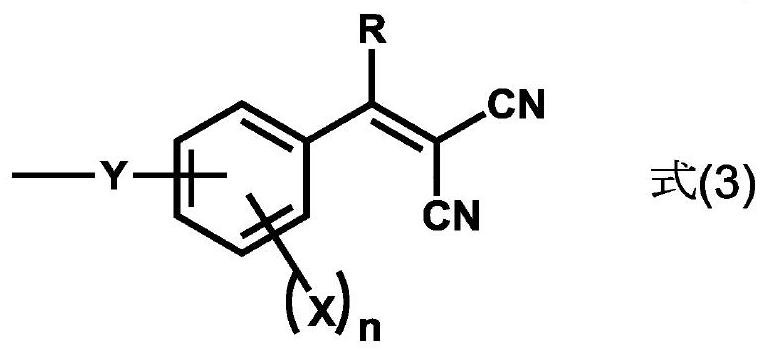

Composition for forming resist underlayer film capable of wet etching, containing heterocyclic compound having dicyanostyryl group

A technology of dicyanostyrene and resist lower layer, which is applied in the direction of organic chemistry, photographic process of pattern surface, photosensitive material used in optomechanical equipment, etc. (Epoxy) resin and other problems, to achieve the effect of good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0213] Next, the content of the present invention will be described concretely with reference to examples, but the present invention is not limited thereto.

[0214] The apparatus etc. used for the measurement of the weight average molecular weight of the polymer obtained in the following synthesis example are shown.

[0215] Device: HLC-8320GPC manufactured by Tosoh Corporation

[0216] GPC column: Shodex〔registered trademark〕Asahipak〔registered trademark〕(Showa Denko Co., Ltd.)

[0217] Column temperature: 40°C

[0218] Flow: 0.35mL / min

[0219] Eluent: Tetrahydrofuran (THF)

[0220] Standard sample: Polystyrene (Tosoh Corporation)

[0221]

[0222] Triazine type epoxy compound (product name: TEPIC, manufactured by Nissan Chemical Co., Ltd., epoxy functionality: 10.03eq. / kg) 10.00g, 4-hydroxybenzaldehyde 12.25g, tetrabutyl bromide 0.85 g and 53.90 g of propylene glycol monomethyl ether were added to the reaction flask, and heated to reflux for 23 hours under a nitrog...

Embodiment 2

[0240] To 7.56 g of a solution (solid content: 23.9% by weight) of the reaction product corresponding to the above-mentioned formula (A-2), 0.27 g of tetramethoxymethyl glycoluril as a crosslinking agent and 0.27 g of tetramethoxymethyl glycoluril as a crosslinking catalyst were added pyridine - 0.02 g of p-toluenesulfonate, 13.78 g of propylene glycol monomethyl ether, and 8.37 g of propylene glycol monomethyl ether acetate were used to prepare a solution of a composition for forming a resist underlayer film.

Embodiment 3

[0242] 3,3',5,5'-Tetrakis(methoxymethyl) was added as a crosslinking agent to 6.96 g of a solution (solid content: 23.9% by weight) corresponding to the reaction product of the above formula (A-2). base)-4,4'-dihydroxybiphenyl (product name: TMOM-BP, manufactured by Honshu Chemical Industry Co., Ltd.) 0.42 g, pyridine as a crosslinking catalyst - 0.02 g of p-toluenesulfonate, 14.23 g of propylene glycol monomethyl ether, and 8.37 g of propylene glycol monomethyl ether acetate were used to prepare a solution of a composition for forming a resist underlayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com