Cotton quilt and preparation method thereof

A technology of a quilt and a breathable layer, applied in the field of bedding, can solve the problems of cross-infection, uneconomical environmental protection, and the difficulty of carrying quilts, etc., and achieve the effects of low production cost, avoidance of cross-infection, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A second aspect of the present application provides a method for preparing a quilt, comprising the following steps:

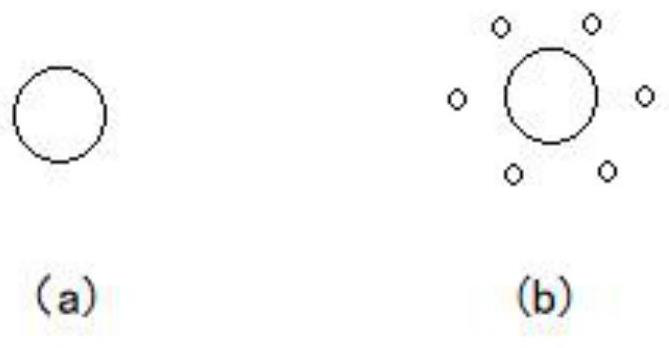

[0051] Prepare SMS non-woven fabric, carry out embossing and perforation process to SMS non-woven fabric, obtain heat-insulating breathable layer, and / or

[0052] Prepare the melt-blown cloth to obtain the thermal insulation and air-permeable layer;

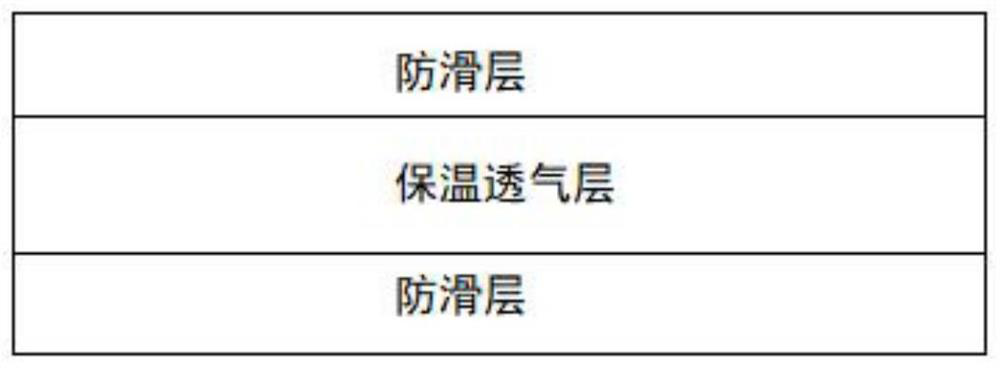

[0053] A heat-preserving and air-permeable layer is stacked between two anti-slip layers to form a sandwich structure, and the quilt is obtained by sewing.

[0054] In the embodiment of the present application, the anti-skid layer is SMS non-woven fabric after embossing, and the surface of the anti-skid layer facing the heat-insulating and air-permeable layer has some first protrusions, which increases the frictional force between the heat-insulating and air-permeable layer. Make the quilt more uniform overall.

[0055] The preparation method of the quilt provided by the application, compared with the pro...

Embodiment 1

[0075] The process of preparing SMS non-woven fabric is as follows: polypropylene raw material + auxiliary functional masterbatch → melting → filtering → metering pump → spinning → cooling → air drafting → web laying → hot rolling → adding antistatic agent and drying → collecting Rolling and slitting → packing.

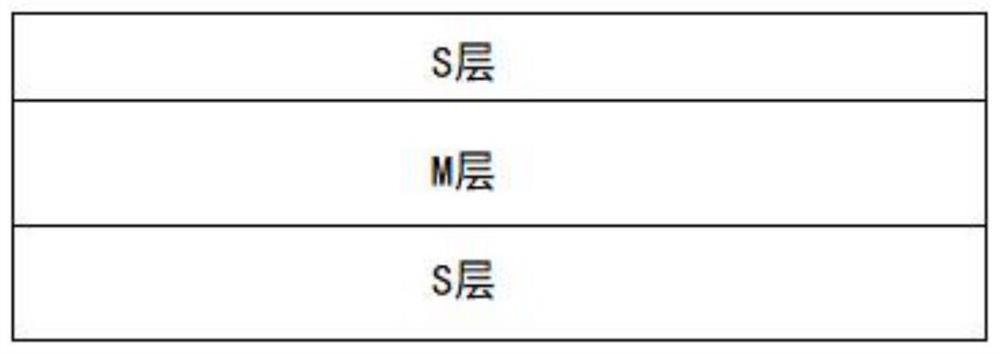

[0076] Specifically, the S layer (spunbonded layer) is made through steps: add 10-20% auxiliary functional masterbatch to polypropylene PP and mix, auxiliary functional masterbatch includes elastic material and soft masterbatch, elastic material and soft The ratio of masterbatch is 25:6, and the components of flexible masterbatch are composed of the following: 60.5% of polypropylene homopolymerization and copolymerization mixture, 22.5% of fatty acid amino derivatives, 15% of polyolefin derivatives, 2% of plastic dispersants, after extrusion The machine is heated and heated to 180-240°C to melt into flowing molten polypropylene, filtered through a filter, and then spu...

Embodiment 2

[0083] Change the thickness of the prepared SMS non-woven fabric, and the remaining steps are the same as in Example 1. The total thickness of the prepared quilt is 1.71mm, the air permeability is 349.98mm / s, the thermal insulation performance is 0.0824㎡.k / w, the softness is 15.42mg / cm, and the elasticity 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com