Mud-resistant water reducing agent and preparation method thereof

A mud-resistant and water-reducing agent technology, which is applied in the field of construction admixtures, can solve problems such as the decline in concrete work performance, the dispersion performance, fluidity and retention performance of polycarboxylate superplasticizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a preparation method of an anti-mud type water reducer, comprising the steps of:

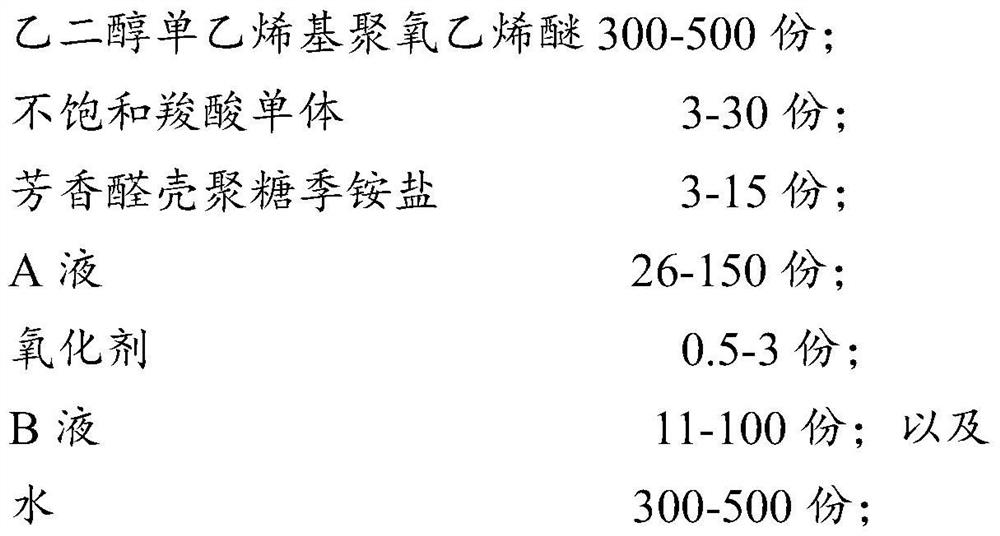

[0068] In parts by weight, 300-500 parts of ethylene glycol monovinyl polyoxyethylene ether, 3-30 parts of unsaturated carboxylic acid monomer, 3-15 parts of aromatic aldehyde chitosan quaternary ammonium salt, 0.5-3 parts The oxidizing agent, 26-150 parts of liquid A, 11-100 parts of liquid B and 300-500 parts of water are placed in the reactor for reaction, and the mud-resistant superplasticizer is obtained after the reaction;

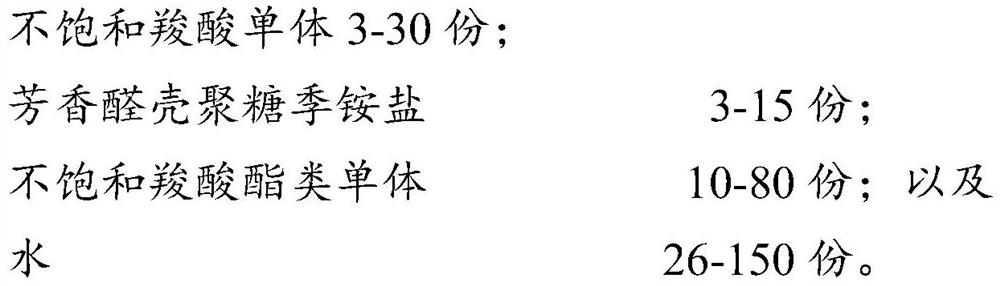

[0069] Wherein, liquid A includes unsaturated carboxylic acid monomer, aromatic aldehyde chitosan quaternary ammonium salt, unsaturated carboxylic acid ester monomer and water;

[0070] Liquid B includes reducing agent, chain transfer agent and water.

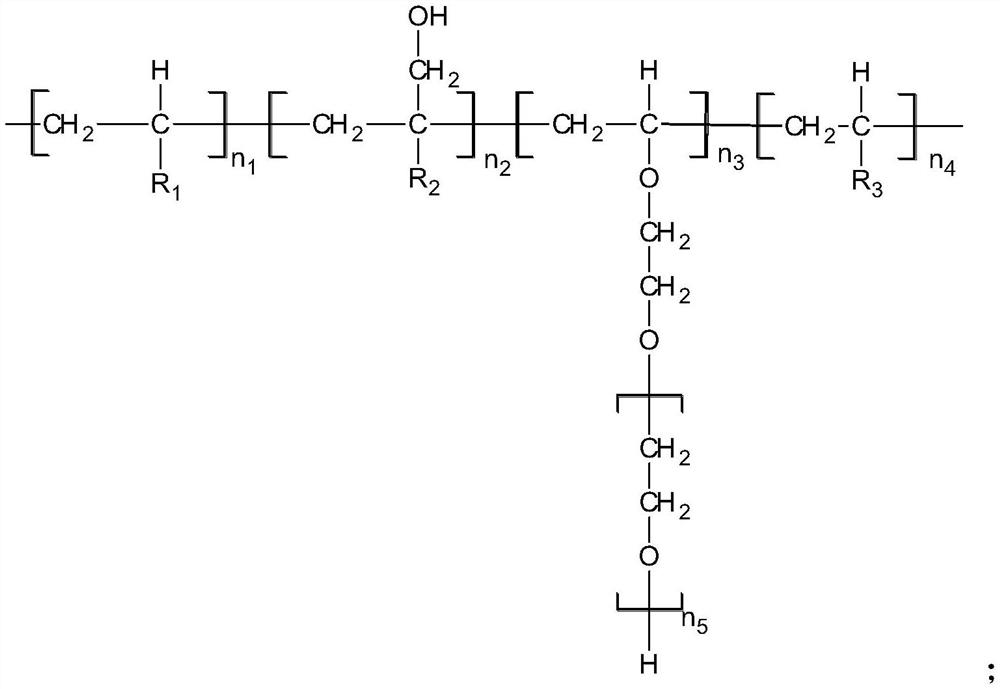

[0071] Specifically, the anti-mud type water reducer provided by the present invention is composed of ethylene glycol monovinyl polyoxyethylene ether, unsaturated carboxylic a...

Embodiment 1

[0114] In terms of weight fraction, 440 parts of ethylene glycol monovinyl polyoxyethylene ether and 400 parts of water are placed in the first reaction vessel and stirred at room temperature until completely dissolved, then 3 parts of acrylic acid and 2 parts of aromatic aldehyde chitosan are added The quaternary ammonium salt is stirred to make the first mixed solution;

[0115] After the first mixing temperature drops to 10-20°C, add 1.5 parts of hydrogen peroxide and 0.2 parts of 1% ferrous ion solution to the first mixed solution, and stir for 5-10 minutes to obtain the second mixed solution;

[0116] Add liquid A and liquid B dropwise to the second mixed liquid at the same time. After the dropwise addition is completed, the dropwise addition time is 40-50 minutes. liquid;

[0117] A neutralizing agent was added dropwise to the third mixed solution to adjust the pH to 5-7, and 25 parts of water was replenished to obtain an anti-mud type superplasticizer with a solid cont...

Embodiment 2

[0121] In terms of weight fraction, 440 parts of ethylene glycol monovinyl polyoxyethylene ether and 400 parts of water are placed in the first reaction vessel and stirred at room temperature until completely dissolved, then 3 parts of acrylic acid and 2 parts of aromatic aldehyde chitosan are added The quaternary ammonium salt is stirred to make the first mixed solution;

[0122] After the first mixing temperature drops to 10-20°C, add 1.5 parts of hydrogen peroxide and 0.2 parts of 1% ferrous ion solution to the first mixed solution, and stir for 5-10 minutes to obtain the second mixed solution;

[0123] Add liquid A and liquid B dropwise to the second mixed solution at the same time. After the dropwise addition is completed, the dropwise addition time is 40-50 minutes. After the dropwise addition is completed, the reaction temperature is 10-35° C. to obtain the third mixed solution;

[0124] A neutralizing agent was added dropwise to the third mixed solution to adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com