Closed-loop pulsating heat transfer pipe and heat dissipation heat exchanger

A closed-loop, heat transfer technology, applied in the fields of heat exchange technology and devices, thermal control, and heat dissipation, can solve the problems of high heat sink, heavy weight, inconsistent temperature of the heat sink, etc. The effect of high production efficiency and productivity, and low investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

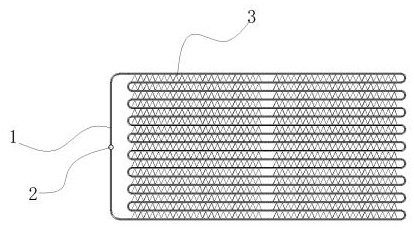

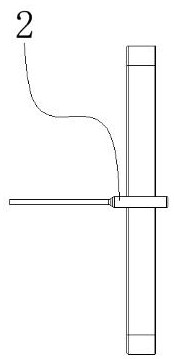

[0023] A new type of pulsating heat pipe

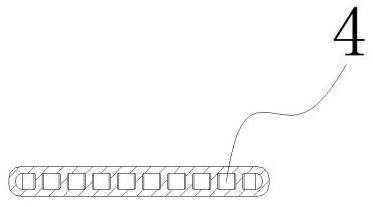

[0024] The pipe body 1 is made of flat porous aluminum pipe fittings. The aluminum pipe is welded and filled with liquid filling pipe fittings after continuous and regular bending to form a closed-loop circuit structure. Pipe fittings, the heat-conducting working medium in the heat pipe boils at low temperature, forming a large number of air bubbles and liquid plugs. The liquid plugs are separated by air bubbles in the tiny tubes. As the temperature of the heat source continues to increase, the heat energy also continues to increase, forming a large number of air bubbles and liquid plugs. Generate, push the liquid plug in the pipe to the condensing section and circulate continuously in the loop pipe. During the circulation process, the working medium continuously vaporizes latent heat, dissipates heat, cools down and flows back to the evaporation section of the heat source, and then circulates continuously to achieve rapid heat dissipa...

Embodiment 2

[0026] A new type of pulsating heat pipe cooling device

[0027] The tube body 1 is fixed (welded or solidified and bonded) on the heat source substrate to become a new type of pulsating heat pipe radiator. In order to improve the heat dissipation and heat exchange efficiency, a heat sink can be installed on the tube body to increase the heat exchange area and improve the efficiency. , forming a super-efficient heat transfer heat exchanger.

[0028] Such as Figure 4 As shown, the radiator bottom plate 5, one side of the radiator bottom plate 5 is connected to the heat source power device (chip), and the other side is connected to the continuous bending closed-loop porous pulsating heat pipe, and the two form a new radiator structure. Larger surface area, forming a new type of pulsating heat pipe radiator, and welding aluminum foil fins are displayed on the pipe fittings, which greatly increases the heat exchange area. High temperature, medium temperature, normal temperature...

Embodiment 3

[0030]A pulsating heat pipe fresh air heat exchange device, which consists of several flat porous pulsating heat pipes made of aluminum and welded with aluminum foil fins. The middle sections of the side-by-side heat exchangers are separated by rubber. In the heat exchange structure pipe, the air fluid in the upper and lower sections of the heat pipe does not circulate. When the heat exchange work starts and the high temperature (low temperature) exhaust gas circulates in the lower layer of the heat exchange structure pipe, the working medium in the pipe body 1 quickly absorbs the heat of the exhaust gas and boils at a low temperature , through the principle of pulsating and oscillating working fluid bubbles and liquid plugs, the liquid plugs are pushed to the upper section of the heat pipe, so that the temperature of the upper section of the heat pipe is close to the temperature of the lower heat pipe, and the fresh air in the upper layer of the heat exchange structure pipe cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com