Water-soluble silver-indium-sulfur quantum dot photocatalyst and room-temperature preparation method thereof

A silver indium sulfur quantum and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, water treatment parameter control, etc., can solve problems such as long reaction time, high reaction temperature, and small reaction vessel capacity, and achieve operational Simple, simple preparation process, and the effect of reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation operation steps of water-soluble silver indium sulfur quantum dot photocatalyst is as follows:

[0029] (1) Take five beakers, add 15 ml of deionized water, 17 mg of 3-mercaptopropionic acid, 6.0 mg of indium nitrate, and 3.4 mg of silver nitrate into each beaker according to the formula, mix well, add sodium hydroxide until the solution is clear, Five identical precursor solutions were obtained. The molar ratio of silver ions to indium ions in the precursor solution was 1:1; the amount of ligand 3-mercaptopropionic acid added was four times the total molar amount of indium nitrate and silver nitrate.

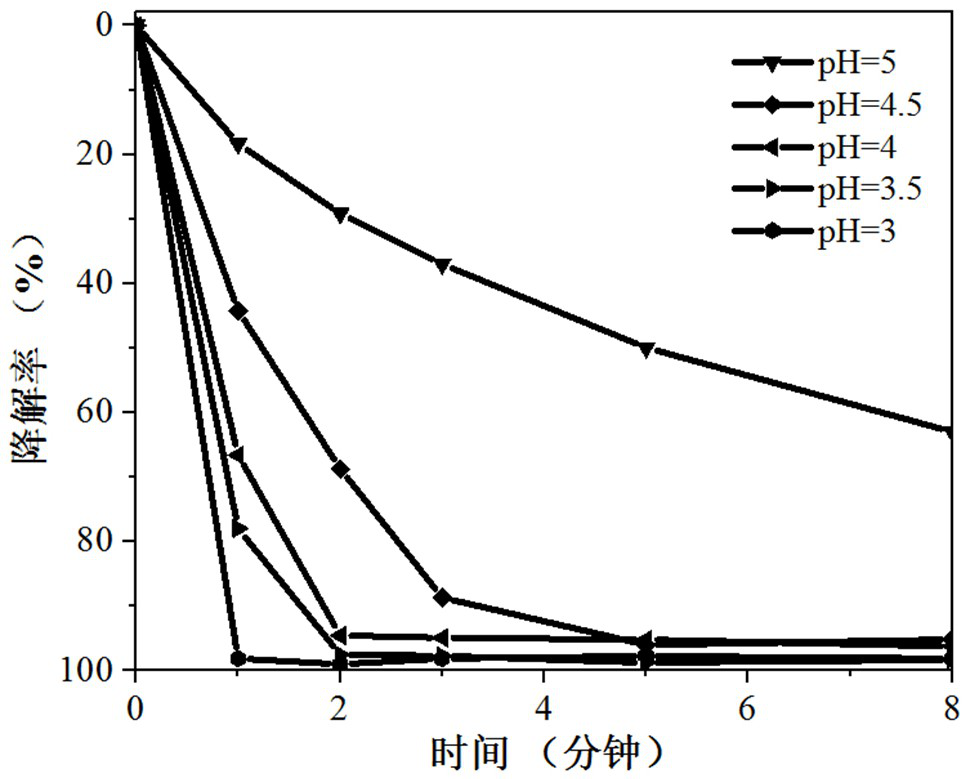

[0030] (2) Add 48 mg of sodium sulfide nonahydrate to the five precursor solutions respectively, the molar ratio of the cationic precursor to sodium sulfide nonahydrate in the five solutions is 1:5, and then use 3-mercaptopropionic acid to dissolve the five The pH value of the precursor solution was adjusted to 3.0, 3.5, 4.0, 4.5, 5.0 respectively, ...

Embodiment 2

[0033] A kind of preparation operation steps of water-soluble silver indium sulfur quantum dot photocatalyst is as follows:

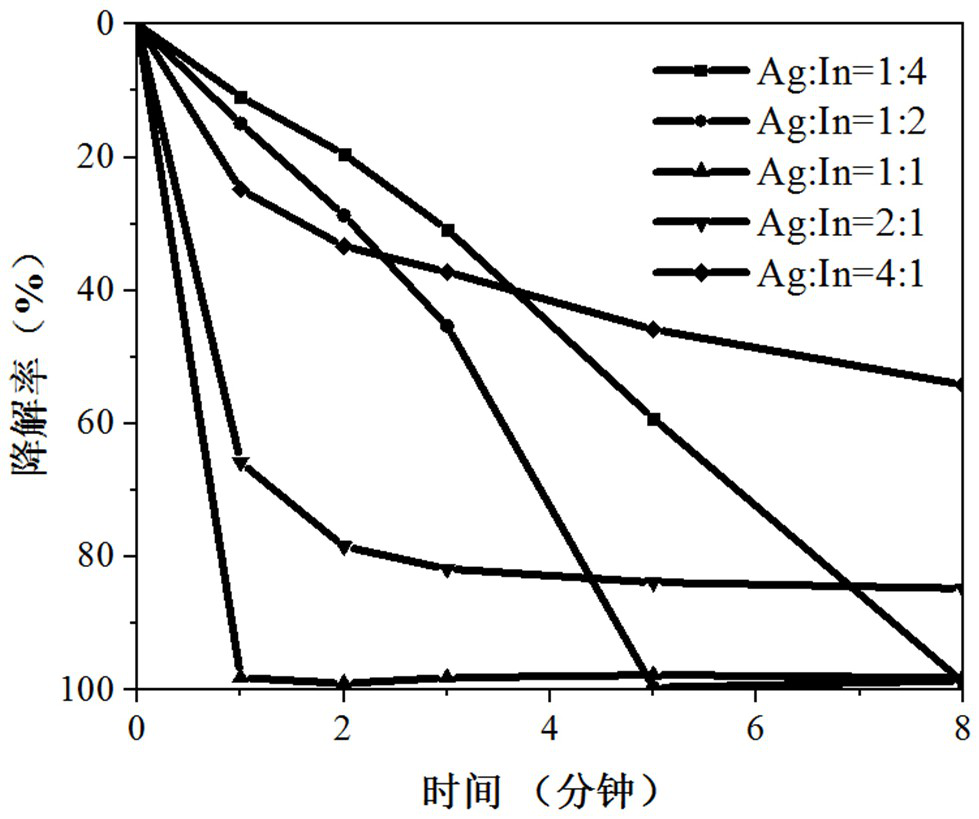

[0034] (1) Take five beakers marked as No. 1-5, add 15 ml of deionized water respectively, and then add 17 mg of 3-mercaptopropionic acid, 9.60 mg of indium nitrate, and 1.36 mg of silver nitrate to No. 1 beaker according to the formula; Add 17 mg of 3-mercaptopropionic acid, 8.10 mg of indium nitrate, and 2.21 mg of silver nitrate to No. 2 beaker; add 17 mg of 3-mercaptopropionic acid, 6.00 mg of indium nitrate, and 3.40 mg of silver nitrate to No. 3 beaker; Add 17 mg of 3-mercaptopropionic acid, 3.90 mg of indium nitrate, and 4.59 mg of silver nitrate; add 17 mg of 3-mercaptopropionic acid, 2.40 mg of indium nitrate, and 5.44 mg of silver nitrate to No. 5 beakers; add hydrogen to each of the five beakers Sodium oxide was oxidized until the solution was clear to obtain five precursor solutions in which the molar ratios of silver cation precursor to ind...

Embodiment 3

[0038] A kind of preparation operation steps of water-soluble silver indium sulfur quantum dot photocatalyst is as follows:

[0039] (1) Take five beakers, add 15 ml of deionized water, 17 mg of 3-mercaptopropionic acid, 6.0 mg of indium nitrate, and 3.4 mg of silver nitrate to each beaker according to the formula, mix well, add sodium hydroxide until the solution is clear , five identical precursor solutions were obtained, and the molar ratio of the silver cation precursor to the indium cation precursor in the precursor solution was 1:1.

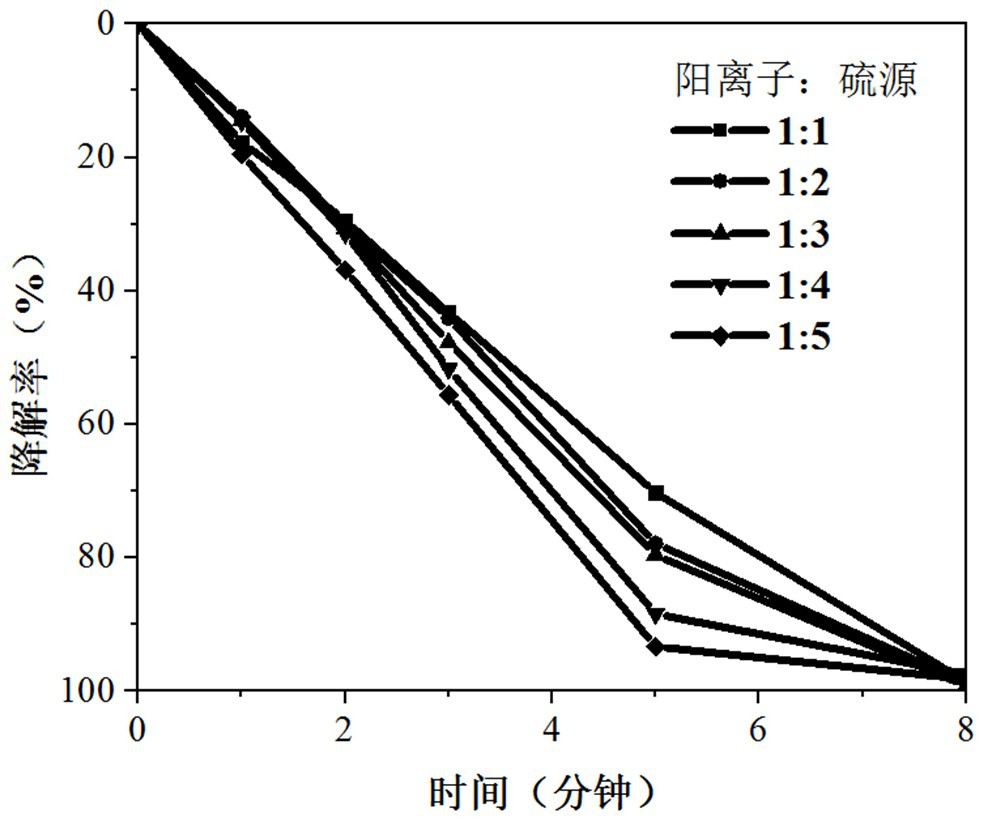

[0040] (2) Add 9.6 mg, 19.2 mg, 28.8 mg, 38.4 mg, and 48 mg of sodium sulfide nonahydrate to the five precursor solutions respectively, and the molar ratios of the cationic precursor to sodium sulfide nonahydrate in the five solutions are 1 :1, 1:2, 1:3, 1:4, 1:5. Then use 3-mercaptopropionic acid to adjust the pH value of five parts of the precursor solution to 3.5, and react for 20 minutes under stirring conditions to obtain five parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com