PLA-based degradable adhesive tape

A technology of adhesive tape and substrate layer, which is applied in the field of degradable packaging material preparation, can solve the problems of poor waterproof performance and few PLA-based degradable tapes, and achieve the effects of improving toughness, excellent biodegradability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

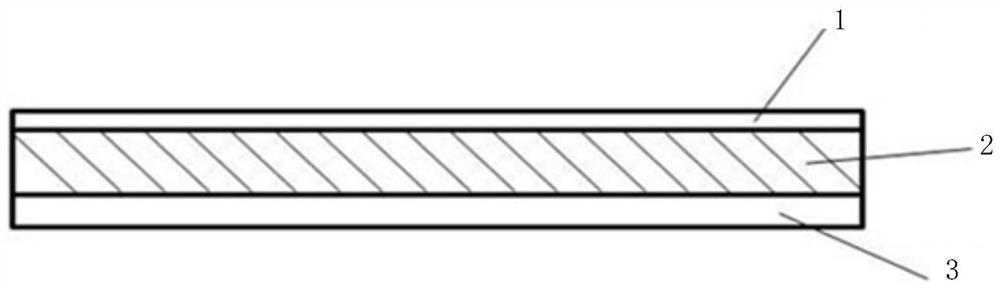

Image

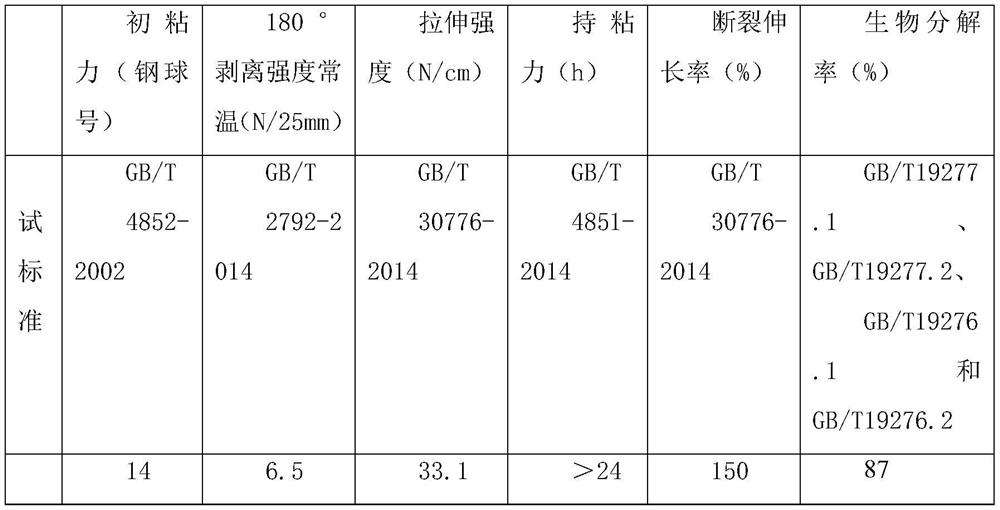

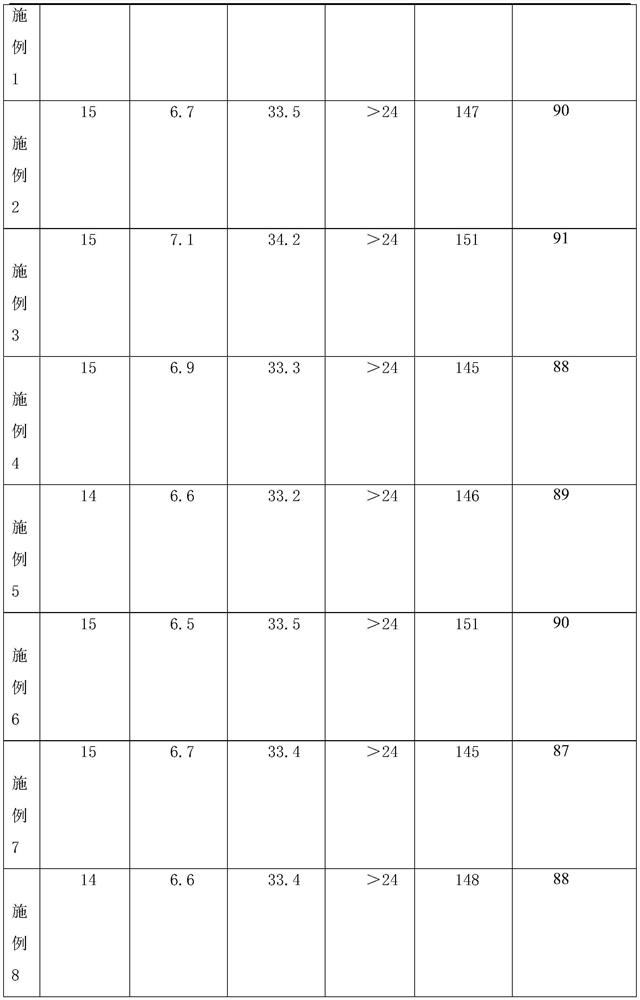

Examples

Embodiment 1

[0021] (1) Preparation of substrate layer

[0022] Stir a mixture of 50 parts of polylactic acid (PLA), 20 parts of PBAT, 20 parts of tapioca starch, 5 parts of nanocellulose and 4 parts of glycerol at 120°C to 150°C for 20 to 30 minutes, then add 0.5 parts of diperoxide Cumene (DCP) and 0.5 parts of zinc stearate are stirred evenly to obtain a mixture; the mixture is extruded and blown into a film to obtain a substrate layer; the semi-finished film is stretched and first dried; The temperature of the first drying treatment step is 170-180°C, and the drying time is 5-10s.

[0023] (2) Preparation of adhesive layer

[0024] Dissolve 5 parts of gelatin in 150 parts of distilled water at 40-50°C, wait until completely dissolved, mix evenly, and let stand for 24 hours to obtain the first glue solution.

[0025] Dissolve 5 parts of 1799 powdered polyvinyl alcohol resin in 150 parts of distilled water at 80-85°C, wait until completely dissolved, mix evenly, and let stand for 24 ho...

Embodiment 2

[0030] (1) Preparation of substrate layer

[0031] Stir a mixture of 60 parts of polylactic acid (PLA), 15 parts of PBAT, 15 parts of tapioca starch, 5 parts of nanocellulose and 4 parts of glycerol at 120°C to 150°C for 20 to 30 minutes, then add 0.5 parts of diperoxide Cumene (DCP) and 0.5 parts of zinc stearate are stirred evenly to obtain a mixture; the mixture is extruded and blown into a film to obtain a substrate layer; the semi-finished film is stretched and first dried; The temperature of the first drying treatment step is 170-180°C, and the drying time is 5-10s.

[0032] (2) Preparation of adhesive layer

[0033] Dissolve 5 parts of gelatin in 150 parts of distilled water at 40-50°C, wait until completely dissolved, mix evenly, and let stand for 24 hours to obtain the first glue solution.

[0034] Dissolve 5 parts of 1799 powdered polyvinyl alcohol resin in 150 parts of distilled water at 80-85°C, wait until completely dissolved, mix evenly, and let stand for 24 ho...

Embodiment 3

[0039] (1) Preparation of substrate layer

[0040] Stir a mixture of 70 parts of polylactic acid (PLA), 10 parts of PBAT, 10 parts of tapioca starch, 5 parts of nanocellulose and 4 parts of glycerol at 120°C to 150°C for 20 to 30 minutes, then add 0.5 parts of diperoxide Cumene (DCP) and 0.5 parts of zinc stearate are stirred evenly to obtain a mixture; the mixture is extruded and blown into a film to obtain a substrate layer; the semi-finished film is stretched and first dried; The temperature of the first drying treatment step is 170-180°C, and the drying time is 5-10s.

[0041] (2) Preparation of adhesive layer

[0042] Dissolve 5 parts of gelatin in 150 parts of distilled water at 40-50°C, wait until completely dissolved, mix evenly, and let stand for 24 hours to obtain the first glue solution.

[0043] Dissolve 5 parts of 1799 powdered polyvinyl alcohol resin in 150 parts of distilled water at 80-85°C, wait until completely dissolved, mix evenly, and let stand for 24 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com