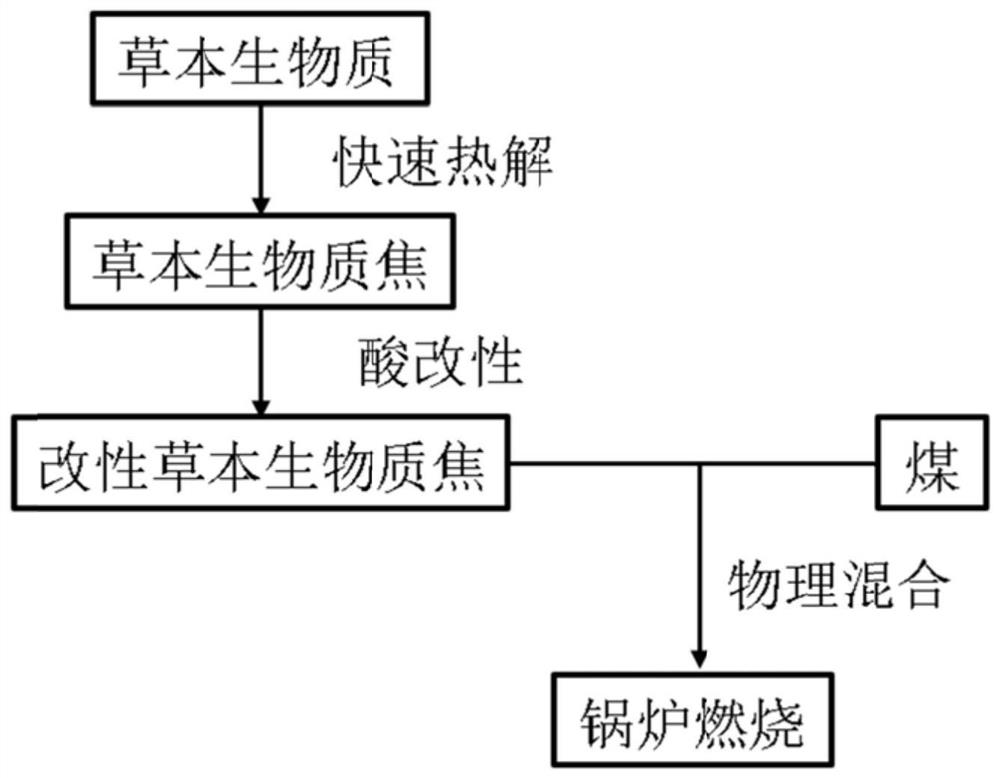

Method for relieving coal combustion contamination problem by using modified herbal biomass coke

A technology of biomass coke and coal combustion, which is applied in the field of power plant chemical industry, can solve the problems of strong fly ash and difficult removal by soot blowing device, and achieve the effect of alleviating the pollution problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Grinding and sieving the straw to below 200 μm;

[0057] (2) place the straw that has been sieved in a drying device at 35° C. for 24 hours;

[0058](3) According to the size of the corundum porcelain boat, put an appropriate amount of straw into the corundum porcelain boat and place the corundum porcelain boat in the room temperature zone of the reactor filled with nitrogen;

[0059] (4) Set the target temperature of the reactor to 500°C; after the temperature of the reactor rises to 500°C, push the corundum porcelain boat to the target temperature zone of the reactor, and keep it warm at 500°C for 30 minutes;

[0060] (5) After the heat preservation is completed and the reactor is cooled to room temperature, the corundum porcelain boat is taken out to obtain straw biomass coke;

[0061] (6) The citric acid solution of rice straw biomass coke and 4mol / L is mixed in the ratio of 5g:200ml to obtain a solid-liquid mixture;

[0062] (7) After stirring the solid-liqui...

Embodiment 2

[0066] (1) Grinding and sieving the wheat straw to below 200 μm;

[0067] (2) Place the sieved wheat straw in a drying device at 40° C. for 24 hours;

[0068] (3) According to the size of the corundum porcelain boat, put an appropriate amount of wheat straw into the corundum porcelain boat and place the corundum porcelain boat in the room temperature zone of the reactor filled with nitrogen;

[0069] (4) Set the target temperature of the reactor to 650°C; after the temperature of the reactor rises to 650°C, push the corundum porcelain boat to the target temperature zone of the reactor, and keep it warm at 650°C for 20 minutes;

[0070] (5) After the heat preservation is completed and the reactor is cooled to room temperature, the corundum porcelain boat is taken out to obtain wheat straw biomass coke;

[0071] (6) Wheat straw biomass coke is mixed with the acetic acid solution of 2mol / L in the ratio of 10g:200ml to obtain a solid-liquid mixture;

[0072] (7) After stirring t...

Embodiment 3

[0076] (1) Grinding and sieving the corn stalks to less than 200 μm;

[0077] (2) Place the sieved corn stalks in a drying device at 45°C for 24 hours;

[0078] (3) According to the size of the corundum porcelain boat, put an appropriate amount of corn stalks into the corundum porcelain boat and place the corundum porcelain boat in the room temperature zone of the reactor filled with nitrogen;

[0079] (4) Set the target temperature of the reactor to 800°C; after the temperature of the reactor rises to 800°C, push the corundum porcelain boat to the target temperature zone of the reactor, and keep it warm at 800°C for 10 minutes;

[0080] (5) After the heat preservation is completed and the reactor is cooled to room temperature, the corundum porcelain boat is taken out to obtain corn stalk biomass coke;

[0081] (6) Mix corn stalk biomass coke with 1mol / L hydrochloric acid solution in a ratio of 20g:200ml to obtain a solid-liquid mixture;

[0082] (7) After stirring the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com